Did you know? Automating your tool changing system can reduce downtime by up to 90%, drastically boosting productivity and profits. The manufacturing world is evolving at breakneck speed, and the secret to staying ahead isn’t just about new machines—it’s about smarter processes. In this feature, we’ll reveal how modern tool changing systems are not just a luxury but a necessity for staying competitive, shrinking downtime, and dramatically accelerating your production floor’s potential.

A Game-Changer: Why Tool Changing Systems Revolutionize Modern Manufacturing

Modern manufacturing thrives on speed, precision, and adaptability. Today, tool changing systems are the silent engine behind these gains. Upgrading from manual tool change to state-of-the-art automatic tool changers or integrating robotic tool changers onto your CNC machines can revolutionize productivity across your facility. By automating the process of switching tools, production lines achieve seamless transitions between operations—spanning from sheet metal fabrication to parts assembly—without the bottlenecks imposed by manual tool changes. This translates to a significantly reduced downtime, optimized labor allocation, and a sharp increase in overall output.

Manufacturers adopting advanced tool changers witness less machine idling and more time spent actually machining or assembling products. With global trade conditions, tariffs, and reshoring adding complexity to supply chains, adopting a robust tool changing system is more than a tech upgrade—it’s a strategy to future-proof operations. From the moment tool holders and robotic arms start working in concert, companies unleash a new era of efficiency. This is why leading manufacturers, such as Schwanog, are reshaping their business models to integrate these technologies, ensuring they remain resilient no matter what the global market throws at them.

Did you know? Automating your tool changing system can reduce downtime by up to 90%, drastically boosting productivity and profits.

What You'll Learn About Tool Changing Systems

Core features of tool changing systems

Comparison between automatic and manual tool changers

How robotic tool changers enhance operations

Real-world case studies, including Schwanog's global adaptation

Commonly asked questions about tool changing

Understanding Tool Changing Systems: An Introduction

What is a Tool Changing System?

A tool changing system is a critical component in modern manufacturing environments, facilitating the quick and accurate exchange of tools during the machining or fabrication process. At its core, it minimizes the delays between different operations on CNC machines, ensuring that the right tool is always available for the next task. Whether you're running production lines with frequent part changes or need the flexibility to switch between processes on demand, tool changing systems transform efficiency by automating what was once a time-consuming manual process.

These systems come in various configurations, from manual tool changers—suitable for prototyping and low-volume runs—to automated tool changers essential for high-volume industrial settings. The most advanced models integrate robotic tool changers capable of communicating directly with machine tool controllers and robots. This means processes can continue with minimal human intervention, slashing labor costs and the risk of human error. Tool holders, robot arms, and advanced ATC systems (automatic tool changers) work jointly to create an agile manufacturing process that’s both scalable and future-proof, perfectly aligning with the demands of today’s global market.

Types of Tool Changers: Automatic, Robotic, and Manual Tool Change

Tool changing systems can be broadly divided into three categories: manual tool changers, automatic tool changers, and robotic tool changers. Each type is suited for specific manufacturing needs. Manual tool changers require human intervention to change tools and are typical in low-volume or prototype environments where flexibility is paramount and speed is a secondary concern. In contrast, automatic tool changers—commonly found in CNC machines—automate the process, enabling rapid and precise tool swaps at the touch of a button or within programmed cycles, greatly reducing the time lost to manual tool changes.

Robotic tool changers take automation a step further, integrating with robotic arms and manufacturing cells for a seamless, fully autonomous approach. These systems are especially beneficial in industries that demand flexible manufacturing and frequent part changeover, such as automotive or sheet metal fabrication. The choice between these depends largely on production volume, required speed, and degree of automation desired. The following table outlines key differences between the most common types.

Type |

Speed |

Application |

Maintenance |

|---|---|---|---|

Automatic Tool Changer |

Very Fast |

CNC, Robotics |

Low |

Robotic Tool Changer |

Fast |

Assembly, Welding |

Medium |

Manual Tool Changer |

Moderate |

Low-volume, Prototyping |

High |

How Tool Changing Systems Work: From Manual to Robotic Tool Changers

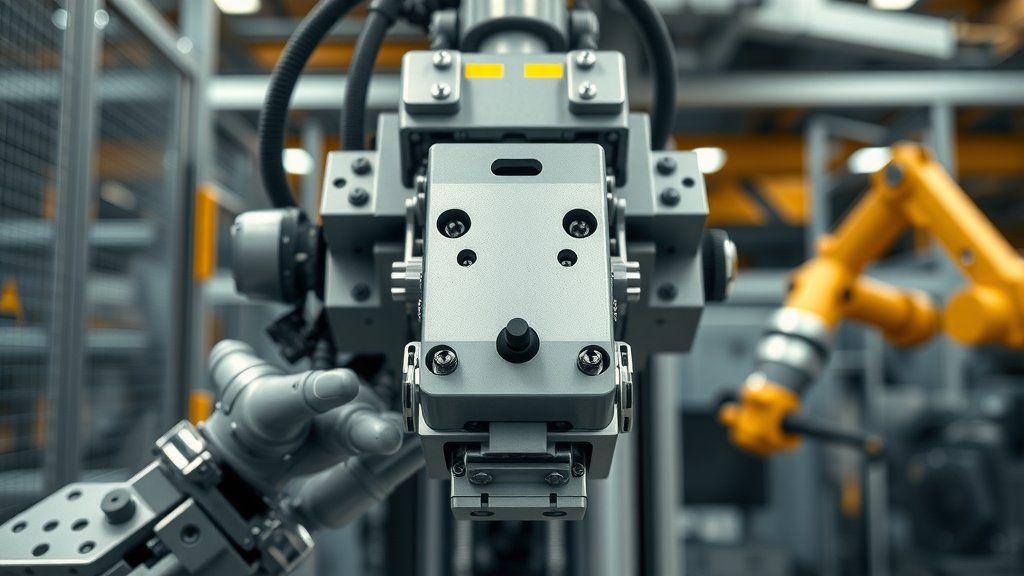

Essential Mechanisms in Automatic Tool Changers

Automatic tool changers (ATCs) lie at the heart of advanced CNC and robotic automation. In these systems, a precisely engineered mechanism selects and swaps tools with minimal human input, enabling the cnc machine or robotic arm to carry out multiple operations without stopping production. Key components include the tool magazine, arm grippers, and precision tool holders. The magazine stores a wide range of cutting and assembly tools; when a tool change is needed, the gripper retrieves the correct tool, aligns it with the spindle or robot end-effector, and completes the switch efficiently.

The process is meticulously programmed into the machine tool’s controller. Sensors and feedback mechanisms ensure each change tool sequence is both accurate and safe. Modern ATCs often feature built-in diagnostics, helping operators monitor tool wear and proactively address maintenance needs. These mechanisms not only prevent costly tooling errors but optimize the use of each tool, increasing tool lifespan and maximizing machine uptime. With automatic tool changers, manufacturers can shift from batch runs to high-mix, low-volume production models without loss in efficiency, creating a truly flexible industrial process.

Integration with Robotic Tool Changers for Advanced Automation

In the era of Industry 4.0, robotic tool changers have become the backbone of high-end automation. Their integration allows seamless switching between different robot end-effectors—grippers, welding torches, sensors, and more—without manual intervention. This advanced changing system is pivotal for flexible manufacturing and for applications where a single robot must perform a wide range of tasks. Core to their efficiency is their precision locking mechanism and connection points, designed for repeated, rapid actuation.

For industries like automotive or electronics, robotic tool changers can significantly shorten cycle times and enable round-the-clock operation. Sophisticated sensors and communication protocols guarantee correct tool engagement, while their modular design allows for quick expansion or adaptation to new processes. By retrofitting existing robot arms with modern tool changers, manufacturers can drastically enhance the flexibility of their facilities—future-proofing their operations for unforeseen shifts in product demand or supply chain unpredictability.

Watch: Demonstration of an automatic tool changer in a live manufacturing environment, showing key efficiency gains.

Benefits of Tool Changing Systems for Increased Efficiency

Downtime reduction

Flexible manufacturing

Optimized tool use and longevity

Improved safety

Deploying tool changing systems delivers a suite of benefits. The most immediate is a steep decline in downtime as machines automatically select and swap tools—no more waiting for operators to change tools manually. This keeps critical equipment, from cnc machines to advanced robotic arms, running at optimal capacity. With reduced manual handling, safety on the production floor also gets a significant boost, decreasing the risk of accidents or mistakes during a manual tool change.

Additionally, these systems extend tool life by ensuring tools are used as intended and are swapped out before reaching failure. With advanced diagnostics, predictive maintenance becomes a reality, reducing costly unplanned stoppages. By having the right tool available whenever required, companies can shift production more freely, adapt to last-minute schedule changes, and support a broader product range. Ultimately, tool changing systems transform the entire industrial process, positioning manufacturers for success in a volatile market.

Choosing the Right Tool Changing System for Your Operation

Key Features to Consider in Tool Changers

Selecting the right tool changing system involves weighing several critical factors. Speed tops the list—automatic and robotic tool changers can operate in seconds, while manual tool changing takes much longer and poses greater risks to consistency. Consider compatibility with your machine tool fleet, especially if running legacy CNC machines or integrating with robotic arms. Look for systems that offer robust diagnostics and preventative maintenance features as standard, which dramatically reduce unscheduled downtime.

In addition, evaluate the system’s product range – can it accommodate the wide variety of tool holders and sizes required in your operation? Durability and ease-of-use are equally vital. The best changers deliver smooth operations regardless of the frequency of tool change cycles or the harshness of the working environment. Companies such as Schwanog have demonstrated how adapting such systems enhances both output and resilience, enabling rapid adjustments whether responding to new tariffs, reshoring trends, or supply chain fluctuations.

Automatic vs. Manual Tool Changers: A Comparative Guide

Speed: Automatic tool changers execute tool change operations in mere seconds, dramatically outperforming manual approaches.

Cost: Upfront expense for automation is higher, but savings in labor and improved efficiency offer a rapid return on investment.

Maintenance requirements: Manual tool changers demand more frequent checks, while automated systems benefit from advanced diagnostics and lower routine upkeep.

Industry relevance: Automatic and robotic tool changers are essential for high-volume, high-mix industries, whereas manual systems remain relevant for prototyping or niche manufacturing.

When choosing between automatic tool changers and manual tool changers, consider your industry’s typical product runs, quality requirements, and flexibility demands. For continuous, high-speed production lines—like those in automotive or electronics—automation is non-negotiable. In contrast, highly specialized or prototype work might still benefit from manual solutions, provided the cost and labor investments are justified.

Industry Spotlight: How Schwanog Adapts Tool Changing Systems for Global Supply Chains

"In a world of shifting tariffs and trade routes, manufacturers like Schwanog illustrate how adaptive tool changing systems help navigate global uncertainty."

Today’s global trade landscape is full of challenges: new tariffs, evolving transportation routes, and unpredictable supply chains. Companies like Schwanog are setting an industry benchmark by embracing highly adaptable tool changing systems. By integrating automatic and robotic tool changers into their production, Schwanog can rapidly adjust operations in response to new market realities. If materials must be sourced from different locations due to tariffs or supply disruptions, tool changers ensure production lines remain flexible and responsive.

Schwanog’s case demonstrates a broader trend among leading manufacturers—those who invest in flexible, high-speed tool change technology are better equipped to navigate global economic shifts. Their ability to retrofit existing machine tools with advanced changers, or rapidly deploy new lines configured for different product ranges, is a clear competitive advantage. As global supply chains continue to evolve, such proactive adaptation is rapidly becoming the standard for success.

Real-World Applications: Tool Changing Systems in Robotics and Sheet Metal Fabrication

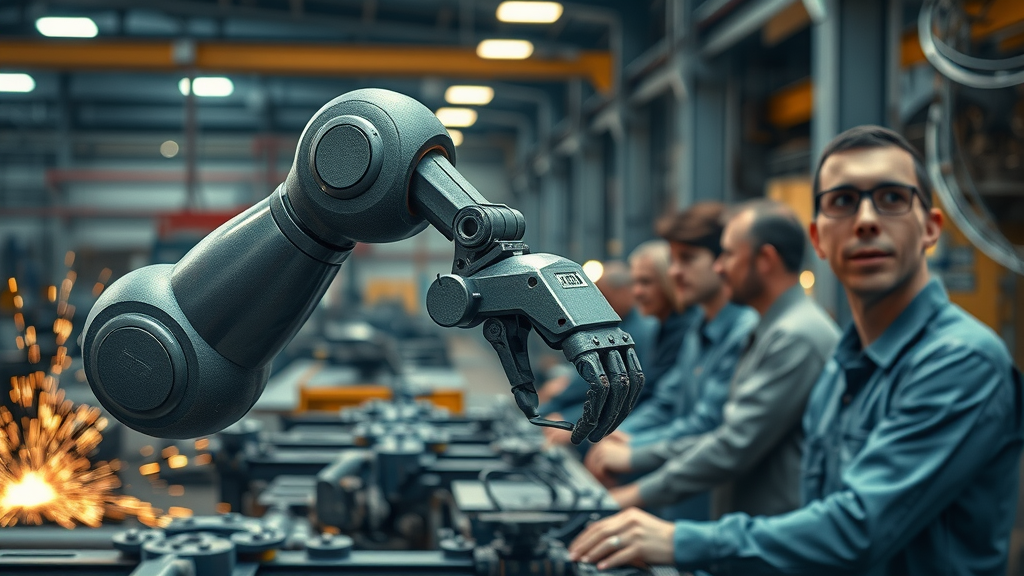

Robotic Tool Changers in Flexible Manufacturing

Flexible manufacturing is all about quickly adapting to varying demand and complex assembly requirements. Robotic tool changers are essential in facilities where a single robot arm must perform a wide range of tasks, from picking and placing components to precision welding. These changers allow robots to swap end-effectors in seconds without any manual intervention, supporting high-mix, low-volume strategies that are increasingly required in competitive global markets.

By utilizing sophisticated robotic tool changers, manufacturers can switch between various tasks without needing multiple robots or excessive downtime for reconfigurations. For instance, a sheet metal fabrication line can operate non-stop as robots efficiently alternate between cutting, bending, and welding tools. This directly contributes to increased throughput, higher quality, and an efficient use of capital equipment—all essential for staying ahead in dynamic, tariff-sensitive sectors.

Tool Change Processes in Sheet Metal Environments

Sheet metal fabrication plants are under constant pressure to deliver on speed and quality, often juggling a diverse range of product designs and sizes. Here, tool changing systems eliminate the need for manual tool changeovers, allowing automatic and robotic changers to facilitate back-to-back production of different components. This makes it possible for fabrication lines to execute custom runs and accept last-minute client changes—without costly downtime.

Operators benefit from simplified workflows, as changers automate the once-tedious process of swapping cutting heads, punch tools, or welding torches. The payoff? Production lines that can adapt on the fly, meet tight delivery deadlines, and achieve consistently high output regardless of fluctuations in order size or design specifications.

Key Considerations: Maintenance and Troubleshooting of Tool Changing Systems

Preventative maintenance for automatic tool changers

Common diagnostic steps for tool change issues

Regular maintenance of tool changing systems is paramount to maximizing uptime and tool longevity. For automatic tool changers, scheduled inspections are critical—operators should check for debris or wear in tool holders, ensure lubrication of moving parts, and use built-in diagnostics to monitor component wear. Preventative maintenance routines typically include checking sensor accuracy, cleaning the magazine or changer head, and confirming all safety interlocks are functional. These small, consistent investments prevent costly catastrophes—such as tool drops or unexpected tool failures—during high-volume runs.

When troubleshooting, operators should follow a systematic approach. Start by reviewing error logs in the ATC or robotic controller. Conduct visual inspections of tool arms and connection points to spot misalignments or obstruction. Often, recalibrating tool holders or tightening connection hardware resolves common tool change hiccups. Training your maintenance staff on these protocols is as vital as investing in the tech itself, ensuring your operation never grinds to a halt unexpectedly.

People Also Ask: Tool Changing Systems FAQs

[[paa]]

FAQs: Everything You Need to Know About Tool Changing Systems

How do automatic tool changers increase productivity?

Automatic tool changers boost productivity by enabling machines to switch tools quickly and seamlessly, reducing downtime between operations and allowing a single CNC or robot to handle multiple tasks in succession without manual intervention.Can tool changing systems be retrofitted to existing equipment?

Yes, most modern tool changing systems are designed with modularity in mind, making it possible to retrofit them onto existing CNC machines and robots to upgrade efficiency without replacing entire production lines.What are the main benefits compared to manual tool change?

Compared to manual tool changes, automatic and robotic tool changers significantly cut down labor costs, minimize the risk of operator error, enhance safety, and increase throughput, making them indispensable for scalable manufacturing.Which industries benefit most from tool changers?

Industries like automotive, aerospace, electronics, and sheet metal fabrication benefit most from tool changers, thanks to their need for high variability, rapid production shifts, and minimal downtime.What maintenance is required for robotic tool changers?

Routine maintenance includes regular cleaning, checking, and recalibrating locking mechanisms, inspecting sensors, and ensuring software updates to maintain reliability and safety standards.

Key Takeaways: Why Invest in Tool Changing Systems Now

Immediate ROI from downtime reduction

Critical role in automated manufacturing

Essential for future-proof production in dynamic global markets

Take the Next Step: Upgrade Your Manufacturing with Tool Changing Systems

Don't miss out! Call Schwanog at 847-289-1055.

Subscribe to Global Trade News for the latest updates. Call 203-271-7991 today.

Add Row

Add Row  Add

Add

Write A Comment