Did you know that sudden servo motor failures cost global manufacturers nearly $10 billion in downtime annually? Struggling with servo motor repairs doesn’t just cause hassle—it threatens productivity, business continuity, and can even reshape a company’s ability to compete on the global stage. In today’s fast-paced industrial environment, finding top-tier servo motor repair services isn’t a luxury; it’s a strategic necessity. This guide will arm you with the knowledge and practical steps to resolve repair challenges, minimize risk, and invest confidently in your facility’s future.

Why Servo Motor Repairs Matter: A Startling Industry Insight

Whether you oversee a sprawling factory floor or run a small-scale workshop, your production lines hinge on the performance of servo motors. More than simple hardware, these motors represent the heartbeat of the automation industry, powering manufacturing robots, CNC machines, and countless other automated systems. When servo motors falter, bottlenecks appear, and downtime mounts. The cost? Not just money, but lost orders, delayed shipments, and diminished trust with key clients.

Recent data confirms a rising demand for high-quality servo motor repair services worldwide. This demand isn’t surprising—many manufacturers depend on a wide range of servo motors from leading brands, each with unique parameters and compatible drive systems. With factories pushing for faster throughput, a single faulty servo motor can halt entire lines. That’s why investing in quality servo motor repairs isn’t just about fixing motors—it’s about protecting your reputation, meeting customer expectations, and staying ahead in a fiercely competitive market. Reliable repair services are your insurance policy against unpredictable failures.

The Rising Demand for High-Quality Servo Motor Repair Services

As global industries automate further, the race for quality servo motor repair expertise intensifies. Manufacturing plants operating 24/7 can’t afford protracted downtime. Servo motor repairs have evolved into a high-priority tactical decision, with repair facilities investing in precision test rigs and diagnostic tools that guarantee quick, accurate results. The automation industry’s pace means the best repair shops offer expedited turnaround times, comprehensive testing, and robust warranties—ensuring that even under the toughest production demands, your systems can return to service rapidly. Request a quote today and experience the peace of mind that comes with a quality-driven repair service.

Companies now routinely evaluate a service provider’s track record for delivering reliable, long-term motor repair solutions. Key selection criteria include the depth of their engineering team, access to OEM parts, certification status, and transparency in diagnostics and pricing. The bottom line: in today’s world market, regular and expert servo motor repairs form the backbone of manufacturing resilience.

What You’ll Learn About Servo Motor Repairs and Repair Services

The fundamentals of servo motor repair

How to identify quality repair services

Common issues with servo motors and how repairs extend lifespan

Steps in the professional repair process

Tips for choosing the best repair service

Understanding Servo Motors and Their Repair Service Needs

Servo motors are engineered for high-precision automation tasks—making their repair requirements uniquely complex. Unlike basic motors, servo motors operate inside tightly controlled feedback loops, often paired with compatible drives to execute nuanced movements. These motors are ubiquitous in everything from robotics and aerospace to food packaging and textiles. The variety—such as AC, DC servo, and brushless models—means each brings its own set of maintenance and repair challenges. Failing to address their unique service needs risks not only operational inefficiencies but also premature machine failure. The stakes for timely, expert servo motor repairs couldn’t be higher in any modern, digitally controlled factory.

Whether you’re running a single dc servo in a CNC lathe or a whole fleet across a production line, regular repair services are crucial for longevity and performance. Well-maintained motors will power your operations for years, but neglect—such as ignoring small signs of malfunction—spirals quickly into major breakdowns. A trusted repair service will not only restore motors but also uncover root causes, offer upgrade options, and keep logs to preempt future failures, thereby ensuring the ongoing health and efficiency of your system.

What Makes Servo Motors Unique in Industrial Applications

The power of servo motors lies in their advanced control systems. Unlike traditional motors, servo motors integrate feedback sensors to constantly monitor and adjust position, speed, and torque. This dynamic feedback is essential for executing precise movements, such as robotic arms on automotive lines or medical device automation. Their complexity, which includes both electrical and mechanical components, means that motor repair requires a deep understanding of each model’s design and how it interacts with compatible drive circuits.

The result is that expert servo motor repair can rejuvenate even aging systems, extending equipment life and reducing the total cost of ownership. Repair technicians use specialized test rigs and diagnostic software to simulate real-world conditions and validate repairs. By focusing on both the electronic and mechanical integrity of servo motors and the synchronization with automation industry standards, companies can future-proof their investments and keep critical systems online with maximum reliability.

Common Signs That Require Servo Motor Repairs

Don’t wait for catastrophe. The most common indicators that a servo motor is failing include erratic or inconsistent motion, excessive vibration, overheating, unusual noises, or a sudden lack of response to control signals. Some issues are subtle—such as gradual loss of accuracy or increased cycle times—while others, like burning smells, signal immediate danger. Addressing these red flags early with a professional repair service can mean the difference between a quick fix and a costly, production-halting failure. Regular testing, including comprehensive test rig procedures, is critical for early detection.

“A servo motor’s performance directly impacts production efficiency—proactive repairs ensure minimal downtime.”

Maintenance logs and regular assessments can help you spot these warning signs before they spiral. Partnering with a repair shop that documents all interventions and can provide a free evaluation helps identify both acute and latent issues, keeping your business ahead of preventable losses.

The Servo Motor Repair Process: Step-by-Step Overview

Initial diagnostics and assessment

Disassembly of the servo motor

Cleaning and inspection of internal components

Replacing worn or damaged parts

Precise reassembly and calibration

Dynamic performance testing

Final quality assurance

Navigating a full servo motor repair calls for both technical expertise and methodical precision. The first step is a comprehensive assessment using diagnostic tools to identify electrical faults, mechanical wear, or software glitches. Once diagnosed, skilled technicians meticulously disassemble the unit—caring for delicate windings, bearings, and feedback devices. Every component undergoes a thorough cleaning, followed by close inspection for corrosion, heat damage, or mechanical fatigue, often using precision instruments and test rig simulations.

Next, technicians replace any defective components, from brushes to feedback encoders, always using OEM or equivalent quality parts. Reassembly demands high attention to detail, especially for aligning rotors and recalibrating sensors for maximum accuracy. Once reassembled, the motor undergoes dynamic performance testing to confirm that repairs meet or exceed manufacturer specifications. Only after final quality assurance checks—often including comprehensive testing under load conditions—is the motor released for return to service. This rigorous process guarantees reliability and efficiency.

Choosing the Right Servo Motor Repair Service Provider

The success of your next servo motor repair depends on your service provider’s credentials—don’t settle for less. Certified and experienced repair teams ensure that equipment is restored according to strict industry standards. Key indicators of a best-in-class provider include ISO certification, experienced engineers, use of OEM parts, and the ability to service a wide range of servo models from leading brands.

“Selecting a certified and experienced repair service minimizes risks and maximizes equipment lifespan.”

Don’t hesitate to request a quote, inquire about diagnostic procedures, or demand free evaluations before committing. The best providers work transparently, offering up-front explanations of pricing, repair timelines, and warranty terms. Relying on certified companies not only minimizes risk but offers peace of mind—allowing your production floor to run without costly interruptions, and ensuring that repair solutions are tailored to your exact operational needs.

Benefits of Professional Servo Motor Repairs vs DIY Solutions

With countless resources detailing DIY “hacks,” it’s tempting to troubleshoot servo motor issues in-house. However, modern servo motors are complex, tightly integrated systems. Professional repair services leverage advanced diagnostics, specialized test rigs, and OEM parts to restore peak function—with the added benefits of warranties and documented service histories. In contrast, DIY attempts risk compounding problems, voiding warranties, and introducing safety hazards. Professional repair shops have access to the latest technologies and testing equipment, ensuring that each component of your servo motor is rehabilitated to precise manufacturer standards, rather than relying on guesswork or incomplete fixes.

Comparison of DIY vs. Professional Repairs |

||

Criteria |

DIY Repair |

Professional Repair |

|---|---|---|

Cost |

Low upfront, higher risk of repeat failure |

Moderate, includes warranty and expert labor |

Turnaround Time |

Variable, often prolonged by troubleshooting |

Predictable, expedited by specialist teams |

Warranty |

Usually none; may void existing coverage |

Comprehensive OEM or service warranty |

Long-Term Reliability |

Risk of hidden defects, unpredictable |

Tested and validated for industrial standards |

Frequently Asked Questions About Servo Motor Repairs

Can servo motors be repaired?

Yes, most servo motors can be repaired by skilled technicians specializing in servo motor repair services. Professional assessment determines the feasibility, costs, and expected outcome.

What is the life expectancy of a servo motor?

With regular maintenance and timely repairs, quality servo motors can last up to 10–15 years in industrial environments. Neglecting servo motor repairs leads to early failure.

How to tell if a servo motor is bad?

Common signs include erratic movement, unusual noises, overheating, and failure to respond to signals. Immediate motor repairs are recommended if these symptoms arise.

How to fix servo not working?

Check power supply and connections as a first step. If issues persist, consult a professional specializing in servo motor repair services for diagnostics and repair.

Real-World Example: How Servotech, Inc. Navigates Global Servo Motor Repair Challenges

Supply Chain Resilience and Adapting Repair Solutions

In the rapidly evolving global landscape, even the most experienced providers like Servotech, Inc. must continually innovate to maintain reliable servo motor repairs worldwide. Disruptions—whether from shifting tariffs, resourcing shortages, or new regulations—test the limits of repair facilities everywhere. Servotech, Inc. answers these challenges by reinforcing supplier relationships, diversifying their global logistics network, and investing in local inventory of OEM parts. The result: minimized downtime even in the face of international supply chain delays.

Their integrated approach—combining local repair facilities, advanced test rigs, and robust remote support—ensures diagnostic accuracy and repair solutions tailored to each client’s unique application. They work closely with engineers around the globe, developing custom repair processes and sharing best practices, which guarantees repairs meet the highest standards in quality and performance. Real-world adaptability is the key to delivering reliable, global servo motor repair solutions in any climate.

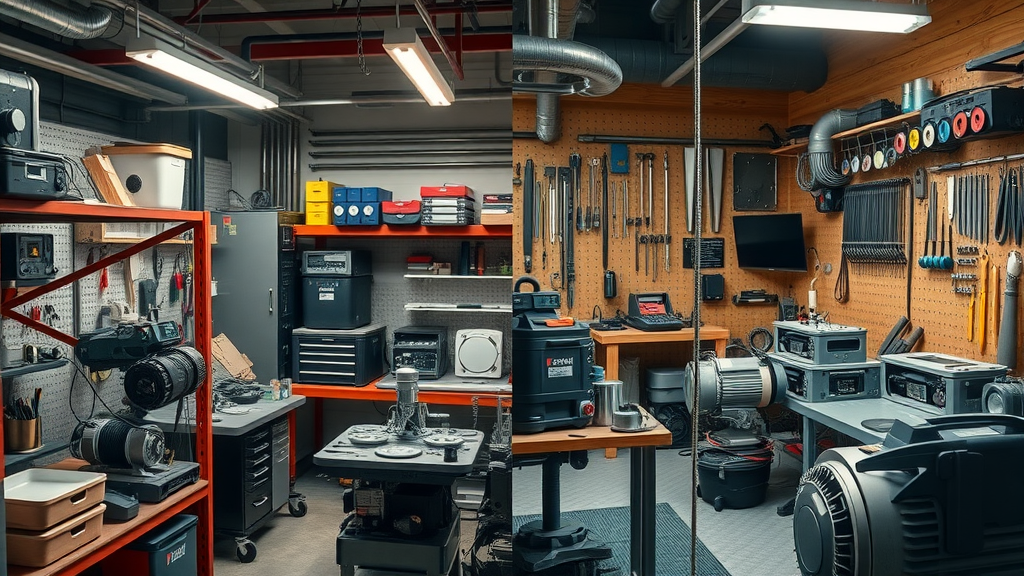

Overview: Servo Motor Repairs in Modern Manufacturing—A Visual Guide

Top Tips for Ensuring Lasting Servo Motor Repairs

Schedule preventive maintenance—Routine checks catch small faults before they escalate.

Use only OEM parts for motor repairs—Authentic components boost longevity and performance.

Partner with trusted repair service providers—Certification and transparency are non-negotiable.

Track and log all repair services for future audits—Documentation simplifies troubleshooting and future upgrades.

These measures extend the life of your servo motors and help maintain consistent, issue-free production. Keeping organized maintenance logs, insisting on genuine parts, and building lasting relationships with certified service shops form the basis of a robust strategy to minimize long-term risk. Incorporating these best practices into your facility workflow can transform how you approach servo motor repairs.

Key Takeaways and Next Steps for Reliable Servo Motor Repair Services

Professional repair services are essential for servo motor longevity

Regular maintenance reduces downtime and operational costs

Consult only certified repair service providers

Integrating these principles into your company’s maintenance strategy ensures operational resilience and cost-efficiency, while a partnership with reputable repair services means fewer emergencies and expedited solutions when issues finally do arise.

Conclusion: Invest in Quality Servo Motor Repairs to Safeguard Your Operations

Proactive investment in professional servo motor repairs safeguards your production line, reduces risk, and secures future growth—don’t let preventable failures disrupt your business.

Stay Ahead: Subscribe for the Latest Global Trade and Industry Updates

Don’t miss out! Call Servotech at 860-632-0164.

Subscribe to Global Trade News for the latest updates. Call 203-271-7991 today.

When dealing with servo motor repairs, it’s crucial to partner with experienced service providers to ensure optimal performance and longevity of your equipment. For instance, Servotech offers comprehensive repair services for over 100 major servo motor brands, providing rapid response times and a one-year unconditional warranty on refurbished motors.

Add Row

Add Row  Add

Add

Write A Comment