Did you know nearly 80% of global manufacturing relies on advanced machine tools? This staggering fact highlights how essential machine tools have become for businesses seeking precision, speed, and innovation in manufacturing. From smart factories humming with automated CNC machines to hands-on workshops deploying traditional lathes and mills, the world of machine tools is rapidly transforming, unlocking new frontiers of efficiency and possibility. If you’re looking to keep your manufacturing edge razor-sharp—or considering an investment in next-generation machining technology—read on. You'll discover why you'll never want to go back to the old way of making things.

Discover the Power of Machine Tools: Why They’re Transforming Manufacturing

“Nearly 80% of global manufacturing relies on advanced machine tools, underscoring their game-changing importance in the modern industry.”

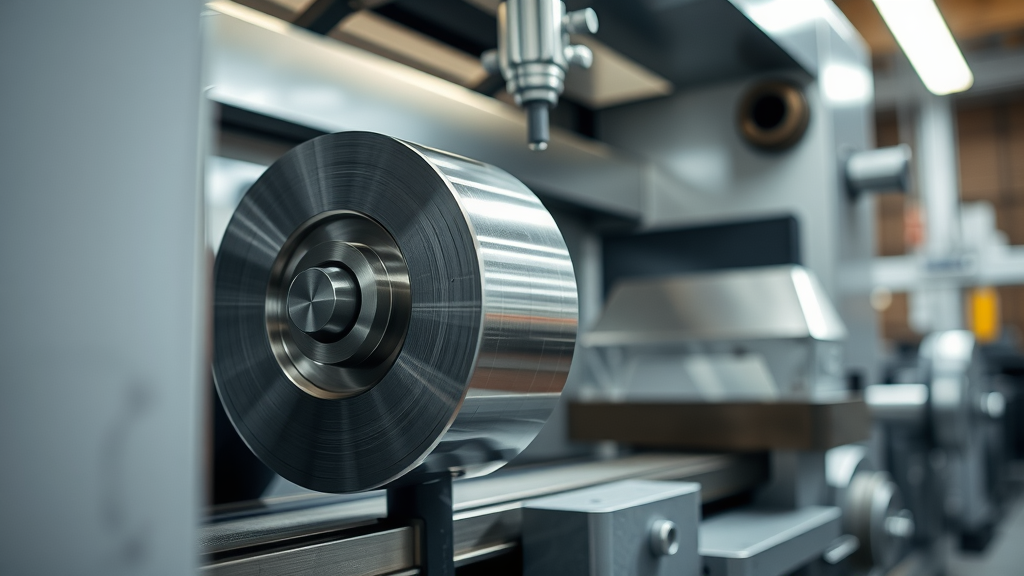

Machine tools are at the heart of the manufacturing revolution, ushering in a new era of precision and speed never before possible. With advanced capabilities, these industrial machine tools empower businesses to deliver products with higher accuracy, minimize waste, and scale complex operations effortlessly. A variety of machine tools—from traditional milling machines to cutting-edge CNC machining centers—have not only improved individual processes, but also streamlined entire global supply chains.

Revolutionary improvements in precision and speed

Streamlining of complex manufacturing processes

Impact on global supply chains

Whether you’re operating a bespoke machine shop or a major OEM production line, breakthroughs in metalworking machine technology are transforming how products are envisioned, designed, and built. As absolute machine tool solutions become more common, companies experience lower downtime, increased automation, and expanded capabilities to tackle diverse projects—sometimes with just a single, smart CNC machine tool on the factory floor.

What You’ll Learn About Machine Tools and Industry Innovations

The essential types of machine tools and their key functions

Emerging technologies in machine tool solutions

How companies like Schütte Corporation excel amid global trade change

Tips for assessing machine tool investments

This article dives deep into the ever-expanding world of nc machine and cnc machine tool technologies—from foundational concepts to advanced manufacturing trends. Get definitive answers, investment strategies, and actionable intelligence tailored for modern manufacturers.

Machine Tool Basics: Concepts, Industry Terms, and Key Features

What is a Machine Tool? Comprehensive Overview

A machine tool is any powered mechanical device that shapes and forms metal, plastic, or other rigid materials through processes like cutting, drilling, grinding, and milling. These tools employ emerging technologies to control the movement and force applied to a workpiece, enabling unimaginable accuracy and consistency. Machine tool terminology covers everything from classic lathes to next-generation CNC machines and even NC machines, serving as the backbone of both manual and highly automated production environments.

In traditional terms, machine tools were operated by skilled machinists in bustling machine shops using manual controls and keen eye judgment. Today, advancements in digital controllers, automation, and AI-powered diagnostics mean that modern cnc machines can handle complex tasks with minimal human intervention. Tools include not just those that cut or grind, but also broaching machines and shaping tools that support intricate forms and detailed part finishes. Across industries as diverse as automotive, aerospace, and consumer electronics, machine tools are essential for shaping our everyday world.

7 Basic Machine Tools Every Manufacturer Should Know

Turning machine (lathe)

Drilling machine

Milling machine

Grinding machine

Shaping machine

Planing machine

Broaching machine

To master the art and science of manufacturing, it’s crucial to understand these foundational machine tool categories. Turnings machines or lathes are indispensable in forming cylindrical shapes and handling metal cutting tasks. Drilling and milling machines allow for detailed hole-making and surface adjustments. Grinding machines take care of fine finishes and removing high spots. Shaping, planing, and broaching machines produce everything from gears to flat surfaces with precision. Any machine shop with these tools can deliver reliable results across a wide spectrum of metalworking requirements.

Machine Equipment vs. Machine Tools: Defining the Difference

It’s easy to mix up machine tools with machine equipment, but there’s a distinct difference. Machine tools are devices that directly cut, shape, or finish a workpiece, such as a CNC milling machine or a grinding tool. In contrast, machine equipment refers to supporting devices, from workholding fixtures and plane gages to automation accessories that aid a machine tool’s operation but don’t shape material on their own.

For example, in a metalworking machine environment, the machine tool could be a sophisticated CNC lathe or a traditional broacher, while the supporting equipment might include conveyors, coolant systems, or safety enclosures. Recognizing this difference can help you maximize the potential of your shop’s investment, streamline procurement, and select the best absolute machine tools or accessories for each application.

Types of Machine Tools: From Basic to Advanced Solutions

Traditional Machine Tools vs. CNC Machine Tool Advances

The leap from traditional machine tools to computer-driven CNC solutions is one of the most important in manufacturing history. Manual lathes and mills—once the lifeblood of machine shops—have gradually given way to versatile, high-performance cnc machines. These digital tools can perform multi-step processes automatically, producing intricate forms and consistent high spots which are difficult or impossible to replicate by hand. This move to automation also significantly boosts productivity, especially in industries requiring absolute machine repeatability and minimal error.

CNC machine tools are now able to tackle complex projects thanks to computerized controls, programmable motions, and integrated sensors. Unlike traditional machines requiring constant adjustments, a single CNC machine can perform the work of several manual machines—and often at much faster speeds. This allows manufacturers to keep pace with global supply chain demands while supporting diverse product lines, all from a streamlined production cell.

NC Machine and CNC Machine Tool Innovations

The development of NC machines (numerically controlled machines) and CNC machine tool technology has redefined what’s possible in modern manufacturing. Instead of relying on physical templates and operator skill, NC and CNC technologies use encoded instructions to deliver pinpoint control across every axis of movement. This means faster changes, improved cutting tool lifespan, and an unmatched ability to form metal with high precision.

Newer innovations—like smart sensors, predictive maintenance features, and IoT integration—continue to drive value for both small machine shops and massive OEM plants. CNC machines can now communicate with other industrial machine tools and ERP systems to optimize production schedules, anticipate maintenance needs, and guarantee consistent product quality. This digital transformation is making absolute machine solutions more robust, more accessible, and more profitable for industry stakeholders everywhere.

Industry Insights: Metalworking and Metal Cutting Technologies

State-of-the-art metal cutting and metalworking machine technologies form the core of most high-volume manufacturing processes. These tools employ advanced materials—such as carbide, ceramic, or diamond-tipped cutting tools—to ensure that even the toughest metals are shaped with accuracy and efficiency. In sectors like aerospace and automotive, modern metalworking machine tools can mean the difference between leading and lagging in innovation.

Whether you’re using a broaching machine for gear production or a high-speed CNC machining center for complex aerospace components, these machines bring industrial precision that manual labor can’t replicate. Successful adoption of new metal cutting solutions not only improves the quality and tolerance of finished products but can also lower overhead costs by reducing need for secondary finishing and manual correction of high spots.

Products and Services: How Schütte Corporation Sets the Standard in Machine Tools

"Schütte Corporation demonstrates resilience and adaptability, leveraging robust machining solutions for precision and efficiency amid global trade uncertainty."

When it comes to products and services that shape the future, Schütte Corporation stands out with versatile solutions for a variety of industries. Their absolute machine tools offerings span from foundational turning and milling equipment to highly digitalized CNC machining centers. With an emphasis on precision, quality, and after-sales support, they empower manufacturers to remain competitive regardless of shifting trade winds.

Comparison of Key Machine Tool Products and Services |

|||

Product/Service |

Application |

Key Features |

Benefit |

|---|---|---|---|

Multi-Spindle CNC Machines |

High-volume, precision part manufacturing |

Complex operations, fast changeovers, automated tool changers |

Extreme efficiency, reduced downtime |

Grinding Solutions |

Surface, cylindrical, centerless finishing |

High spots removal, programmable controls |

Superior finishes, consistent tolerances |

Custom Automation Systems |

Process integration, smart factory solutions |

IoT connectivity, advanced robotics |

Unmatched scalability, improved safety |

Maintenance & After-Sales Support |

All machine tool installations |

Remote diagnostics, preventative care, operator training |

Longer machine life, reduced downtime |

By embracing innovation and a global outlook, Schütte Corporation ensures its product range—from classic industrial machine tools to cutting-edge machining centers—keeps customers one step ahead in a rapidly changing market.

Selecting Machine Tools: Factors to Consider for Optimal Performance

Application requirements (metalworking, plastics, etc.)

Precision and quality needs

Automation and CNC controls

Machine tool cost and ROI analysis

Maintenance and after-sales support

Choosing the right machine tool—whether a simple broaching machine or an advanced CNC machine—demands a clear understanding of your process needs. Start by defining the application. Are you seeking a solution for heavy-duty metalworking, or do you need fine tolerances for precision parts? Next, consider whether CNC capability or full automation is essential for your workflow. The return on investment goes beyond sticker price, involving factors like machine tool durability, high-quality output, and after-sales support.

It’s critical to partner with a provider that offers robust products and services including technical support, preventive maintenance, and easy-to-access spare parts. Forward-thinking companies, such as Schütte Corporation, take pride in providing not only top-tier equipment but also the expertise and infrastructure to support their customers for the full lifecycle of a machine tool investment.

Case Study: Schütte Corporation Navigating Global Trade with Machine Tools

Real-world implementation of absolute machine tools

Adaptations to tariffs and reshoring trends

Enhancements in manufacturing efficiency with advanced technology

In recent years, Schütte Corporation has demonstrated how agile responses to global trade changes—such as new tariffs and the increased pace of reshoring—are possible with adaptive machine tool strategies. By modernizing with absolute machine and CNC machine tool innovations, the company increased production flexibility and minimized the impact of supply chain uncertainties.

Their adoption of high-speed machining centers, coupled with real-time analytics and automated systems, has enabled clients to maintain product consistency and quality even as regulations shift. These practices highlight the critical role advanced machine tools play not only in daily production but in macro-level business strategy as well.

Watch industry experts demonstrate the latest advances in cnc machine tool solutions and discover why more manufacturing teams are investing in automated, smart equipment to strengthen their operations.

People Also Ask: Machine Tools Q&A

What are the 7 basic machine tools?

The seven basic machine tools every manufacturer should know include: turning machines (lathes), drilling machines, milling machines, grinding machines, shaping machines, planing machines, and broaching machines. These tools form the core of almost every machine shop and are essential for forming, finishing, and precision cutting tasks in metalworking and beyond.

What is the machine tool?

A machine tool is a powered device used to fabricate parts by removing material, often via metal cutting, drilling, grinding, or milling. Traditional examples include lathes and drills, while modern forms range from advanced CNC machines to specialized metalworking machine centers, each designed for precision and efficiency.

What are machine equipments?

Machine equipment refers to all auxiliary devices that support the main function of machine tools, such as clamps, workholding fixtures, plane gages, and automated conveyors. While they don’t directly shape or cut material, these pieces of equipment enable smoother, safer, and more accurate operation of your core machine tools.

What are industry machine tools?

Industry machine tools are specialized tools and systems used in manufacturing sectors such as automotive, aerospace, energy, and consumer goods production. This category includes everything from classic milling machines and grinding tools to innovative absolute machine tools and CNC machining centers engineered for high-throughput, consistent output.

Machines that Power Industry: Absolute Machine, CNC Machine, and Future Trends

Rise of smart manufacturing

Integration of IoT with CNC machines

The growing role of sustainable machining practices

Cutting-edge machine tools are at the center of smart manufacturing trends. IoT technology enables cnc machines to communicate with other machines, optimize workflow, and predict maintenance. Sustainability is also shaping equipment choices, with newer absolute machine tools designed for energy efficiency and minimal waste. By staying ahead of these trends, businesses can ensure long-term operational and environmental success.

Learn from leading manufacturing industry professionals how the latest machine tool technologies, changing trade policies, and sustainable practices are shaping the future of global manufacturing.

Key Takeaways for Investing in Machine Tools

Prioritize performance matched to workload

Monitor trade policies and tariffs for strategic timing

Partner with forward-thinking technology providers

Investing in the right machine tool is about more than current needs—consider future scalability, global trade trends, and choosing a provider who understands innovation and service.

FAQs: All About Machine Tools

How to service machine tools for extended life?

Regular maintenance—like lubrication, scheduled inspection of high-wear components, and timely part replacement—can greatly extend the lifespan of both manual and advanced CNC machine tools. Partner with providers offering remote diagnostics and preventive care, such as Schütte Corporation, for the best results.What safety protocols are essential for CNC machines?

Modern CNC machines require strict adherence to operational safety guidelines. Always enforce safety lockouts, proper training for operators, and use of shields and emergency stops. Smart sensors on advanced models can also help automate many aspects of safety monitoring.How do machine tools impact product quality?

The precision of machine tools determines final product accuracy, surface finish, and dimensional reliability. Well-maintained and properly aligned equipment reduces the risk of high spots and ensures consistent quality across production runs.What is the difference between manual and automatic machine tools?

Manual machine tools require hands-on operator input and adjustment, best suited for prototyping or small runs. Automatic or CNC machine tools leverage digital programs and robotics to handle complex or repetitive tasks, dramatically boosting speed, efficiency, and uniformity.

Stay Ahead in Machine Tools: Get Global Trade Updates

Call Schutte Corporation at 517-782-3600.

Subscribe to Global Trade News for Latest updates. Call 203-271-7991 today.

Conclusion: Elevate Your Manufacturing Strategy with Machine Tools

Unlocking the true value of machine tools means more than upgrading equipment—it’s committing to future-ready manufacturing, smarter investment, and an agile response to industry change. Start your journey today.

Add Row

Add Row  Add

Add

Write A Comment