Did you know? In just one year, over 35% of advanced manufacturing facilities worldwide adopted laser welding technology to accelerate production, marking a dramatic shift towards precise, high-efficiency manufacturing . As global industries race toward smarter automation, laser welding stands at the forefront—offering unmatched speed, accuracy, and adaptability. Whether you oversee a busy factory floor or manage OEM supply chains, understanding this revolutionary process is critical to staying competitive and future-ready.

Unlocking Efficiency: How Laser Welding Technology is Redefining Modern Manufacturing

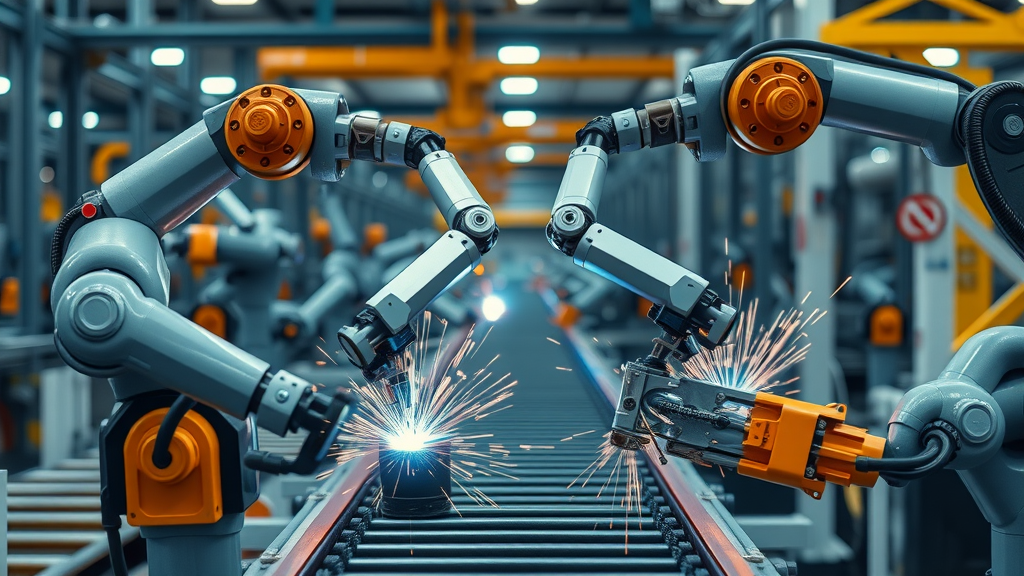

Laser welding technology is dramatically reshaping the landscape of modern manufacturing, allowing businesses to accomplish more, with less. By harnessing ultra-focused laser beams, manufacturers can perform high-speed, precise welds on even the most complex assemblies. This means reduced production times and significant improvements in product quality, a game-changer whether you're working with automotive components or intricate electronics. The practical impact? Companies are achieving output previously thought impossible using traditional welding processes, slashing turnaround times while increasing durability and performance.

Take, for example, a state-of-the-art automotive manufacturer. By integrating automated laser welding machines, they've achieved higher welding speeds and deeper penetration—creating stronger bonds with less thermal distortion and minimal post-processing. This isn't limited to heavy industry either. Providers of medical devices and consumer electronics now rely on laser beam welding for ultra-fine, micro-precision joints essential for reliability and compliance. With laser welding technology, efficiency gains aren't just theoretical—they're documented, measurable, and driving manufacturing forward at unprecedented speed.

A Surge in Automation: The Global Impact of Laser Welding Technology in Numbers

"In 2023, over 35% of advanced manufacturing facilities globally adopted laser welding technology to streamline production—demonstrating a seismic shift toward precise, high-efficiency processes."

- The scientific principles behind laser welding technology

- Differences between beam welding, laser beam welding, and keyhole welding

- The specific benefits laser welding provides versus traditional welding technique

- Types of lasers and welding machines used in industrial applications

- How to choose the right welding process for your production needs

- Real-world case studies illustrating the impact of laser welding

What is Laser Welding Technology and Why is It Transforming Manufacturing?

At its core, laser welding technology utilizes highly concentrated beams of light—generated by advanced laser sources—to fuse metals or thermoplastics with such precision that traditional welding methods struggle to compete. Unlike arc welding or resistance welding, the laser beam welding process delivers a tightly directed and incredibly intense heat source, capable of deep penetration and high welding speed, while preserving delicate materials from excessive heat or distortion. This unique ability results in consistently high weld quality and the flexibility to work with thin materials or intricately shaped components.

But why is laser welding so transformative? Its impact stems from a remarkable combination of benefits—ultra-fast cycle times, minimal heat-affected zones, and the ability to automate with robotic welding machines on a mass scale. Manufacturers across industries are shifting to laser beam welding techniques to produce stronger, cleaner, and smaller weld seams, essential for everything from next-generation vehicles to life-saving medical instruments. As the manufacturing world continues evolving toward digital connectivity and lean production, laser welding technology offers an unmatched edge in versatility and scalability.

Exploring the Core Principles of Laser Beam Welding

To grasp the science behind laser beam welding , start with its laser: a device that emits a coherent, focused light beam with tremendous power density. When directed at a material, this intense energy rapidly melts and fuses the target—delivering precision that rivals micro-surgical tools. The process is managed by advanced optics, sensors, and computer controls, making it possible to adjust power, focus, and movement for each unique application. This flexibility allows manufacturers to achieve deep penetration welds or delicate, micro-scale joints, depending on product requirements.

Unlike traditional beam welding techniques that rely on bulkier, less efficient heat sources, laser beam welding offers significantly improved control. By adjusting laser parameters such as wavelength, pulse duration, and focal spot size, fabricators can tailor the process for everything from high-speed automotive assemblies to detailed electronics enclosures. It's this adaptability that has made laser welding a staple in both high-weld-strength industrial applications and environments where thermal conductivity and heat-affected zones must be closely managed.

Comparing Modern Laser Welding Techniques to Traditional Welding Process

While arc welding and resistance welding have long been industrial staples, laser welding technology pushes the boundaries by offering new levels of speed, accuracy, and product consistency. Traditional welding processes frequently introduce wide heat-affected zones, spatter, or distortion, especially on thin or sensitive materials. In contrast, the laser’s concentrated heat source enables deeper, stronger joints and high welding speeds—without the drawbacks.

The efficiency gains are complemented by greater repeatability, higher welding speed, and the ease of automation. Laser beam welding systems can be directly integrated with industrial robots and assembly lines, unlocking seamless production for even the most challenging applications. As manufacturing demand for miniaturized components and lightweight materials increases, the limitations of conventional welding become clear—making the switch to modern laser welding techniques not just a technological upgrade, but a business imperative.

"Laser beam welding isn’t just about speed—it’s about reaching depths and accuracies traditional welding can’t match."

How Does Laser Welding Work? A Deep Dive into Beam Welding Fundamentals

The laser welding process relies on physics principles that transform a focused light beam into a powerful tool for joining materials. In beam welding , a high-intensity laser is directed through an optical system and concentrated on the workpiece surface. The energy density at the focal point is so great it instantly melts the target material, producing a weld with minimal surrounding heat input. The result? Clean, strong seams and an unmatched ability to weld in tight corners, complex geometries, or even in hard-to-reach assembly points.

Key to its versatility is the ability to control laser parameters to suit every application: from deep penetration for thick sheet metals to conduction welding for surface-bonded, low-heat applications. This makes laser beam welding ideal for prototyping, batch manufacturing, or high-volume, automated production. By delivering a concentrated heat source, laser welding solutions can operate at high welding speeds, all while minimizing waste and improving product quality.

The Science of Laser Beam and Deep Penetration Welding

Deep penetration welding is one of laser technology’s signature talents. As the laser beam strikes the material, its energy is absorbed and converted into heat so rapidly that it forms a vapor-filled cavity—known as a keyhole —deep within the metal. This quick formation allows the laser to achieve full-penetration welds in materials that would otherwise require multiple passes or complex joint preparations. The highly focused nature of the laser beam also means the heat-affected zone remains tightly controlled, preserving the mechanical and metallurgical properties of adjacent areas.

The unique aspect of this approach is its adaptability. By tuning the laser beam’s power density or changing the welding technique, manufacturers can switch from conduction welding (which creates fine, shallow welds perfect for electronics) to keyhole welding (which delivers deep, narrow seams needed for structural or load-bearing applications). The ability to adjust parameters on the fly gives manufacturers an unprecedented edge in versatility, allowing for a wide range of industrial and high-precision applications.

Anatomy of a Laser Welding Machine: Precision Components Explained

Every modern laser welding machine is a symphony of advanced engineering. At its heart is the laser source (fiber laser, CO2 laser, or diode laser), which generates the high-intensity beam. This beam then travels through a series of mirrors and focusing optics, ensuring the energy is precisely delivered to the weld site. Critical sensors monitor beam alignment, focal position, and material response in real time, feeding data back to a digital control panel.

Supporting these core components are robust cooling systems that maintain laser stability, specialized fixtures for part alignment, and safety systems to protect operators from laser exposure. The modular nature of laser welding machines also lets manufacturers swap out laser sources, automation modules, or clamping mechanisms based on their specific welding process —increasing throughput without sacrificing quality. This modularity, combined with user-friendly software and automation options, makes today’s laser welding machines both powerful and highly adaptable to any welding application.

Keyhole Welding vs. Conduction Welding: What Offers the Greatest Advantage?

The choice between keyhole welding and conduction welding revolves around application needs. Keyhole welding , with its deep penetration, is ideal for thick, structural metals where weld strength and single-pass efficiency are paramount. This is common in industries such as automotive, energy, or aerospace, where load-bearing joints and robust connections are a must. Its advantage lies in creating high weld quality with minimal distortion, even in high welding speed scenarios.

Conversely, conduction welding offers superior surface finish and is perfect for thin materials or micro-joining tasks—such as electronics and fine medical device parts—where excessive heat would damage sensitive components. The laser beam gently melts only the upper layer, ensuring limited thermal impact and a pristine weld seam. Understanding these distinctions is crucial: by choosing the right welding method for each application, manufacturers maximize both productivity and quality, securing their technological advantage in an increasingly competitive market.

Types of Laser Welding Techniques and Welding Machines

The world of laser welding technology is richer and more varied than ever before. Modern manufacturers can choose from a wide range of laser welding machines and beam configurations, adapting the technology to materials as diverse as stainless steel, aluminum, precious metals, plastics, or composites. The most common types of lasers used in welding include fiber lasers, CO2 lasers, and diode lasers—each with its own strengths and optimal applications.

The right combination of machine and laser type is determined by production volume, part materials, desired weld speed, and system integration requirements. Fiber lasers are popular for their energy efficiency and the ability to weld reflective materials; CO2 lasers excel in plastics and non-metals; while diode lasers shine in precision applications involving delicate or highly conductive metals. Advanced welding machines come equipped for both manual operation and full automation, allowing seamless integration into robotics and Industry 4.0-ready assembly lines.

A Wide Range of Laser Welding Machine Options for Every Application

The evolution of welding machines in the laser sector means manufacturers no longer have to compromise between flexibility and throughput. Entry-level, benchtop systems are optimized for low-volume or prototype work, providing all the core benefits of laser welding in a compact package. For mid-to-high-volume production, modular and automated laser welding cells offer integrated robotics, vision systems, and sophisticated process controls—ensuring repeatable results and compatibility with almost any welding application .

Regardless of scale, the common denominator is high weld quality , fast setup, and operator safety. These welding machines can be configured to handle small, intricate parts or large assemblies, adapting seamlessly to evolving production needs. With the ability to integrate with IoT networks and digital quality assurance platforms, today’s laser welding equipment is as future-ready as the industries it serves.

Types of Lasers: Fiber, CO2, and Diode Technologies Unveiled

| Laser Type | Suitable Materials | Key Applications |

|---|---|---|

| Fiber Laser | Stainless Steel, Aluminum | Automotive, Electronics |

| CO2 Laser | Plastics, Non-Metals | Packaging, Medical Devices |

| Diode Laser | Precious Metals | Jewelry, Battery Manufacturing |

Each type of laser brings unique advantages: fiber lasers provide high power density and are highly efficient; CO2 lasers are versatile for organic and non-metallic materials; and diode lasers, while generally lower in power, excel at delicate micro-welding with outstanding energy control. The right choice amplifies throughput, achieves consistent weld geometry, and meets the highest standards in demanding industries.

Unmatched Benefits of Laser Welding Technology in Modern Industrial Applications

What truly sets laser welding technology apart is its trifecta of speed , precision , and deep penetration . The ability to form joints in milliseconds, to reduce the affected zone nearly to zero, and to automate virtually any aspect of the process means manufacturers enjoy next-level performance regardless of batch size or complexity. Whether welding automotive axles, battery casings, or microscopic medical stents, the result is always the same: unmatched weld integrity and reduced production lead times.

Automation is another cornerstone benefit. Integrated laser welding machines work seamlessly with industrial robots to support high-quality mass production . This dramatically increases throughput and cuts labor costs, while advanced controls guarantee consistent results even in high-mix, low-volume manufacturing environments. Companies leveraging laser beam welding and automation are finding themselves far ahead—achieving targets that were previously unreachable with traditional methods.

Speed, Precision, and Deep Penetration: Next-Level Performance

In performance-focused industries, welding speed, power density , and penetration depth are everything. Laser welding technology delivers on all fronts, making it the go-to solution for racing against tight deadlines while still exceeding stringent quality criteria. Manufacturers regularly report doubling their throughput without increasing defect rates—directly thanks to the unparalleled control and throughput that only laser beam welding offers.

The process is particularly valuable where cleanliness, minimal post-processing, or fusion of non-ferrous and dissimilar materials is needed. With a carefully tuned process, even the most challenging joints—ranging from ultra-thin foils to thick chassis beams—can be completed quickly and reliably. In every scenario, the minimal heat-affected zone results in pristine welds and less wasted material, lowering the overall cost per finished unit.

Laser Welding and Automation: Enabling High-Quality Mass Production

Laser welding technology is uniquely suited for automation. Advanced welding machines can interface directly with robotic arms, material handling systems, and quality inspection units. This not only ensures high-weld consistency but also supports scalable, 24/7 production schedules needed in today’s global supply chains. Automation-friendly design means human operators can focus on system oversight and optimization, reducing risk and increasing uptime.

Integration with digital production systems—such as MES (Manufacturing Execution Systems) or cloud-based analytics—means every weld is documented, traceable, and subject to continuous process improvement. The result is superior weld quality at unprecedented scale, catering to the automotive, aerospace, and medical sectors where quality and traceability are non-negotiable.

- Superior weld quality with minimal heat-affected zone

- Deep penetration capability for thick and challenging materials

- Greater process control for repeatable results

- Compatibility with robotics and automated lines

- Reduced post-processing and finishing

"Laser welding has enabled us to cut lead times in half and deliver flawless results on a wide range of materials." — Plant Operations Manager, Tier 1 Automotive Supplier

Key Considerations and Potential Downsides of Laser Welding Technology

No solution is entirely without challenges, and laser welding technology requires careful planning prior to implementation. Manufacturers must weigh aspects such as up-front investment, operational complexity, and the suitability of materials for laser welding techniques. While the process offers high welding speed, certain materials—especially highly reflective or inconsistent alloys—may require specialized setup or frequent parameter adjustments to avoid quality issues.

Another crucial consideration lies in safety and regulatory compliance. High-power lasers require strict operator training, comprehensive safety shielding, and real-time monitoring to prevent exposure risks. These requirements increase the initial barrier to entry but are essential for safe, long-term operations. Manufacturers must also budget for ongoing maintenance, periodic system recalibration, and potential upgrades as applications evolve.

Understanding the Limitations of Beam Welding and Deep Penetration Techniques

While beam welding offers unmatchable speed and versatility, not every material or application lends itself to the deep penetration welding process. Highly reflective materials—such as copper or certain aluminum alloys—may scatter part of the laser energy, reducing penetration or causing spatter. In addition, joints with poor fit-up or contamination can compromise weld consistency, especially in automated, high-speed production environments.

Thickness and geometry of the workpiece also influence results. Extremely thin materials risk warping, while excessively thick components might require pre-heating or multi-pass strategies. Understanding these nuances ensures that manufacturers get the most from their laser welding operations while minimizing unpredictable downtime or costly defects.

Initial Costs and Operational Demands of Industrial Welding Machines

Investing in modern laser welding machines —especially automated, high-power configurations—requires significant capital. The costs cover not only the laser source and delivery optics, but also robotic integrations, safety systems, and ongoing staff training. While returns often materialize through efficiency gains and defect reduction, it’s essential to factor in timelines for ROI, production volume, and maintenance needs when justifying the transition.

In addition, running and maintaining a laser welding system demands attention to consumables (such as diode modules or protective windows), regular equipment calibration, and robust procedure documentation. Organizations must commit to workforce development so that every operator and engineer is fully versed in both operational protocols and safety best practices.

Mitigating Quality Control Issues in Automated Laser Welding

Even with the best laser beam welding systems, process drift and material variability can pose quality control challenges. Automatic parameter monitoring, real-time vision systems, and closed-loop control modules are critical tools to detect irregularities and make on-the-fly adjustments—ensuring every weld meets exacting standards.

Manufacturers must also establish rigorous inspection and testing protocols, utilizing destructive and non-destructive evaluation techniques to validate weld integrity. By fostering an environment of continuous improvement, companies can mitigate risks, reduce rework, and maintain the consistent high weld quality that defines successful laser welding operations.

Use Cases: Laser Welding Technology in Action Across Industries

The laser welding process finds a home in diverse industries, each taking advantage of its distinct strengths—from deep penetration on heavy equipment to fragile seams in microelectronics. Understanding real-world use cases demonstrates how this technology is rewriting the rules across the manufacturing spectrum.

From automotive body panels to battery electrodes, and even turbine blades for sustainable energy, laser welding machines are making production safer, faster, and more reliable. Here’s how today’s innovators are rethinking manufacturing with laser welding at the core.

Electronics and Medical Devices: Micro-Precision with Laser Beam Welding

For sectors where precision is paramount, like medical device assembly and electronics manufacturing, laser beam welding is indispensable. The process enables assembly of miniature components where even the slightest thermal distortion or spatter could ruin the finished product. For example, modern pacemakers, surgical tools, and sensor packages depend on defect-free bonds produced by highly controlled conduction welding methods.

Similarly, consumer technology companies leverage laser welding for tasks such as battery tab welding and miniature circuit connection—achieving the high welding speed and thermal control needed to prevent damage to sensitive components, all while delivering ultra-high repeatability.

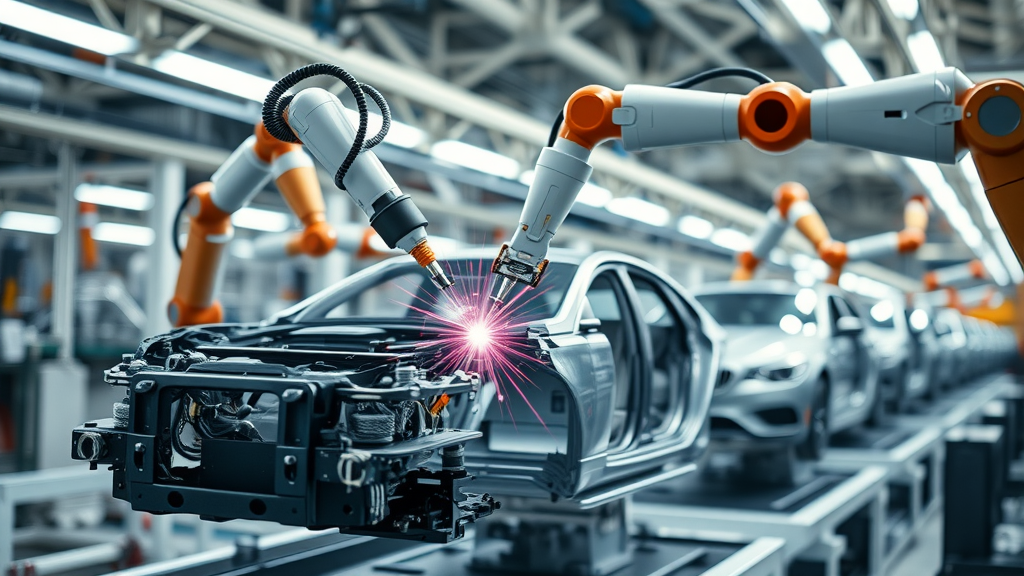

Automotive: From Conduction Welding to Structural Assemblies

In the automotive world, laser welding technology supports both lightweight assembly and high-strength structural work. Manufacturers utilize a mix of conduction welding for trims, panels, and delicate joints, and keyhole welding for core structural elements—axles, chassis, powertrain housings—where deep, robust joints must withstand years of stress and vibration. The integration of laser welding machines with robotic cells ensures high-welding speeds, rapid changeovers, and complete data traceability for crash-critical components.

The combination of deep penetration and compatibility with a wide range of metals—including advanced high-strength steels and aluminum alloys—enables automotive leaders to boost safety and reduce vehicle weight, directly translating into lower fuel consumption and emissions.

Aerospace and Energy: Overcoming Tough Material Challenges with Deep Penetration Welding

Aerospace and energy industries deal with some of the world’s toughest weldment requirements: exotic alloys, ultra-thick plates, and extreme operational environments. Here, laser welding technology enables deep, sound welding in nickel alloys, titanium, or high-strength stainless steel—materials that are notoriously challenging for traditional arc welding.

Laser systems can be tuned for full-penetration and defect-free results in critical structures (think: jet engine parts, turbine disks, or nuclear fuel rods), supporting not just durability but also regulatory and quality compliance. In renewable energy, the speed and adaptability of laser welding help manufacturers scale battery, fuel cell, and wind turbine production efficiently and with minimal waste.

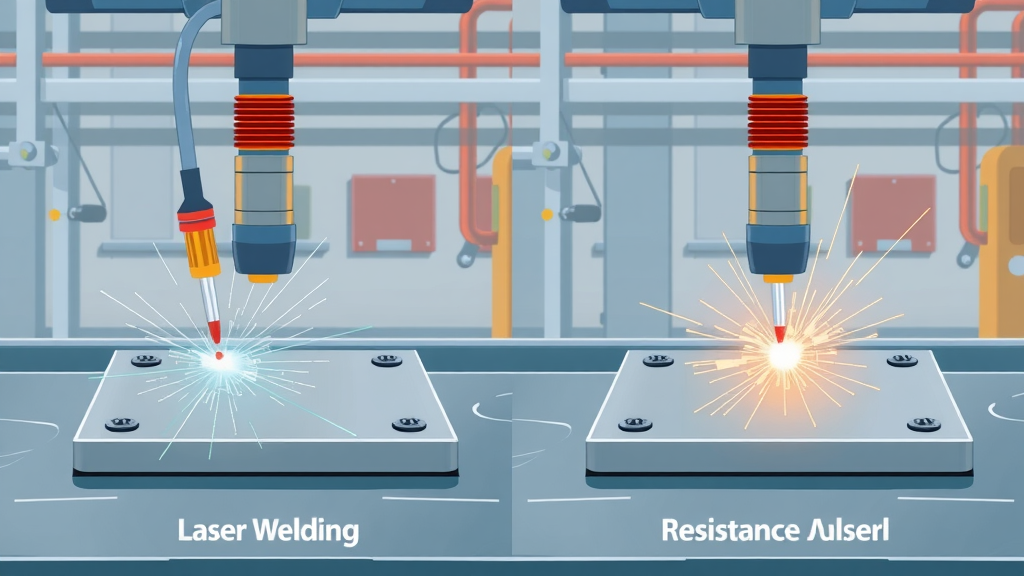

Comparing Laser Welding Technology to Traditional Welding Methods

Laser welding stands apart from arc welding and resistance welding thanks to its precision, minimal heat-affected zone, and rapid processing capability. Here’s how key welding techniques stack up against each other:

Beam Welding, Arc Welding, and Resistance Welding: A Side-by-Side Performance Analysis

| Welding Technique | Speed | Penetration | Heat-Affected Zone | Automation Ready |

|---|---|---|---|---|

| Laser Beam Welding | Very High | Deep | Minimal | Yes |

| Arc Welding | Moderate | Moderate | Large | Limited |

| Resistance Welding | Fast | Shallow | Minimal | Yes |

The data show that laser welding technology surpasses other methods in several key areas: speed , deep penetration , fine control over the heat-affected zone, and easy compatibility with modern automated manufacturing. Forward-thinking manufacturers are embracing these advantages to drive down costs, improve quality, and keep pace with ever-changing market demands.

- Reduced defects and rework

- Lower energy consumption for batch production

- Seamless integration with Industry 4.0 initiatives

People Also Ask

What is laser welding technology?

Laser welding technology is an advanced manufacturing process that uses a concentrated laser beam to join metal or thermoplastic materials. The extremely focused energy enables precise, rapid, and strong welds with minimal distortion, making it the technique of choice for industries demanding accuracy and speed.

What are the downsides of laser welding?

Major downsides include high initial equipment costs, the need for skilled operators, sensitivity to material type and fit-up, and strict safety protocols due to the power of the laser beam. In certain cases, spatter or microcracking in deep penetration welds may also occur if parameters are not optimized.

Does a laser welder really work?

Absolutely. Laser welders are widely used for spot, seam, and deep penetration welding in sectors such as automotive, electronics, aerospace, and medical device manufacturing, regularly achieving results that surpass traditional welding in both quality and productivity.

How much does a laser welder cost?

Laser welder costs can range widely: entry-level manual machines may start around $15,000–$30,000, while advanced automated laser welding systems for industry can exceed $250,000, depending on power, automation, and features.

Frequently Asked Questions on Laser Welding Technology

- How does beam welding differ from laser beam welding?

- What are the key safety practices for operating a laser welding machine?

- Which materials work best for deep penetration laser welding?

- How does conduction welding improve surface finish?

- Can laser welding technology be retrofitted to existing production lines?

Essential Tips for Incorporating Laser Welding Technology into Your Manufacturing Process

- Assess your production needs and material types

- Compare different laser welding machines and their automation capabilities

- Evaluate ROI: initial investment vs. long-term gains in quality and efficiency

- Consult with experts for application-specific guidance

- Plan for training, maintenance, and integration

"Switching to laser welding technology positioned our company to outpace competitors in both speed and quality." — Operations Director, U.S. Industrial Manufacturer

Key Insights: Why Laser Welding Technology is Pivotal for Future-Ready Manufacturing

- Laser welding delivers deeper, stronger joints than most traditional methods

- Integration with robotics ensures unmatched precision and repeatability

- Versatile machine types serve a wide range of materials and applications

- Consistent quality yields faster turnaround and lower defect rates

- Investment in laser welding technology pays off in efficiency and scalability

Ready to Transform Your Supply Chain with Advanced Laser Welding Technology?

Facing Tariff Pressures? It’s Time to Reshore Smarter. At Electronic Service Products, we specialize in precision laser machining solutions that meet the highest quality standards—onshore, on time, and on budget. Whether you're looking to reshore your manufacturing or avoid the mounting cost of overseas tariffs, we offer the speed, precision, and flexibility your supply chain demands. 👉 Call today 203-265-4167 or go to espcnc.com/request-a-quote

Laser welding technology is revolutionizing modern manufacturing by offering unparalleled precision, speed, and efficiency. For a comprehensive understanding of this transformative process, consider exploring the following authoritative resources:

- “Laser Welding” ( ipgphotonics.com )

This resource provides an in-depth overview of laser welding, detailing its principles, advantages, and applications across various industries.

- “What is Laser Welding and How Does It Work?” ( twi-global.com )

This article delves into the mechanics of laser welding, explaining how the process operates and its benefits over traditional welding methods.

By consulting these resources, you can gain a deeper insight into how laser welding technology is reshaping production processes and driving efficiency in manufacturing.

Add Row

Add Row  Add

Add

Write A Comment