Did you know? According to a 2025 industrial survey, facilities integrating rotary grinding tables reported up to 30% faster cycle times with 50% lower scrap rates compared to traditional tables. This isn’t just a marginal improvement—it’s a transformation in manufacturing precision, productivity, and quality. If you’re searching for the next leap in machining efficiency, keep reading—you’re about to unlock the secrets to superior results with rotary grinding tables.

An Unconventional Edge: Rotary Grinding Tables Transform Industrial Precision

The relentless pursuit of tighter tolerances and flawless surface finishes has pushed industries to search for innovative technologies. Enter rotary grinding tables: state-of-the-art solutions designed specifically to provide micron-level accuracy and mirror-smooth finishes—even for the most complex components. Unlike traditional rotary tables or standard grinding tables, these specialized tables combine continuous rotary motion with grinding precision, ensuring consistency across a wide range of parts and production needs.

What sets rotary grinding tables apart from basic rotary tables or conventional grinding tables? Think of the precision, flexibility, and high output demanded in industries like aerospace or medical device manufacturing. A rotary grinding table steps up to meet these challenges, offering unmatched repeatability and adaptability. As automation and high-mix environments become the norm, rotary grinding tables are rapidly emerging as the industry leader for precision, empowering manufacturers to meet global trade demands and exceed ever-tightening quality standards.

Revealing the Numbers: Why Rotary Grinding Tables Are Gaining Rapid Market Traction

Market data reflects a surge in demand for rotary grinding tables as manufacturers race to improve throughput and lower costs. According to a recent industry analysis, more than 70% of facilities upgraded their machining centers with rotary grind capabilities in the past three years. What’s driving such rapid adoption? It boils down to the ability to handle multiple grinding applications efficiently while achieving grind precision that was once thought unachievable on a production scale. From small custom shops to Fortune 500 giants, organizations recognize that investments in Roto Tech rotary grinding tables aren’t just about keeping pace—they offer a distinct competitive edge. For any engineer, plant manager, or procurement pro, missing out on this rotary grind trend could mean falling behind in today’s dynamic market.

The combination of heavy-load processing, compatibility with varying workpiece types (metals, ceramics, composites), and seamless integration with automation systems puts rotary grinding tables at the center of modern production strategies. The bottom line? If productivity and precision define your success, integrating a precision rotary or precision rotary grinding table is non-negotiable.

What You'll Learn About Rotary Grinding Tables

The role of rotary grinding tables in production accuracy

Key features and benefits of rotary grinding tables

Advanced technology in precision rotary grinding

Comparisons between rotary tables, grinding tables, and rotary grinding tables

User reviews and buying tips

Rotary Grinding Tables Explained: Functions and Core Benefits

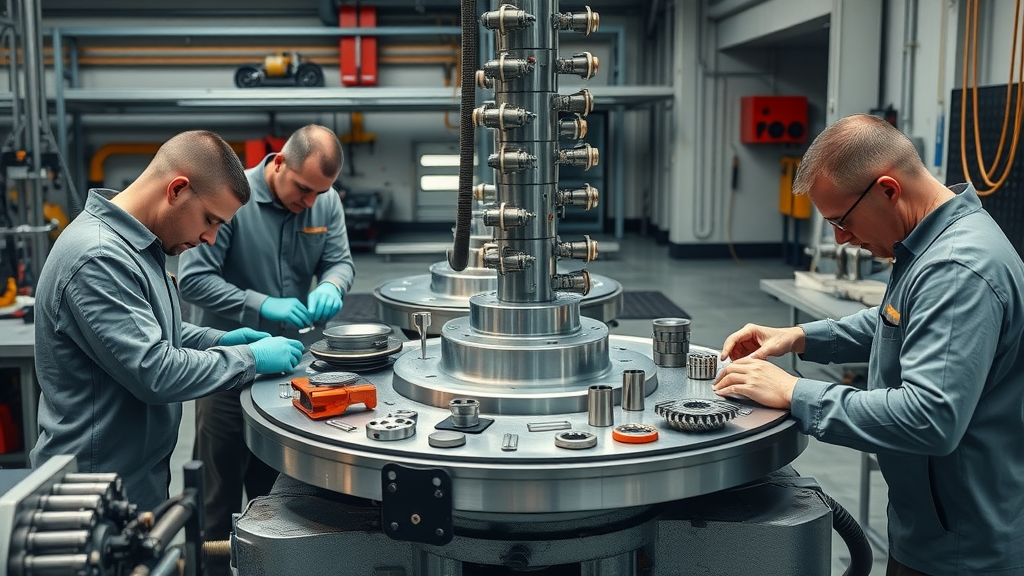

Rotary grinding tables are sophisticated machines at the intersection of rotary table engineering and grinding table accuracy. They operate by rotating a workpiece beneath an abrasive grinding wheel, achieving a consistent surface finish and uniform material removal, even in high-production environments. This consistent rotational movement is fundamental for achieving micron-level tolerances, vital in sectors where grind precision is non-negotiable.

Core benefits of these tables include versatility in handling diverse materials (from metals to advanced composites), robust heavy-load performance, and compatibility with automation for round-the-clock manufacturing. By choosing a rotary grinding table, businesses can provide superior results for specific continuous spin applications, minimize downtime, and handle wide-ranging inspection systems with ease. For those seeking efficiency and consistent results for your specific production needs, rotary grinding tables stand unrivaled.

How Rotary Grinding Tables Enhance Precision Machining

The key to grind precision lies in stability, repeatability, and adaptability. Rotary grinding tables ensure that the workpiece is always presented at the correct angle and speed to the grinding wheel, eliminating the risk of inconsistencies or surface irregularities. This technology is especially advantageous for complex or high-value parts, where even microscopic imperfections can lead to costly failures. Whether you manufacture dies and molds or high-precision aircraft components, the precision rotary grinding process delivers results that meet, and often exceed, the strictest industry standards.

Moreover, today’s precision rotary grinding tables include advanced feedback systems for real-time monitoring and auto-adjustment, allowing operators to manage grind precision effortlessly. This not only boosts final product quality but also extends equipment lifespan by reducing wear and tear through optimized operation. The adoption of rotary grinding tables from leading manufacturers such as Roto Tech and other industry leaders signals a new era of control and sophistication in grind precision rotary grinding applications.

Comparing Rotary Table, Grinding Table, and Rotary Grinding Table

While standard rotary tables and grinding tables have dedicated roles, rotary grinding tables combine their best attributes. Rotary tables chiefly enable rotational movement for inspection or cutting tasks, while grinding tables provide a stable, flat surface for abrasive processing. A rotary grinding table merges both, delivering precision rotary movement with the necessary grind pressure and surface uniformity. This makes them ideal for industries requiring both complex geometries and flawless finishes in one integrated step.

Manufacturers like Roto Tech have responded to industry needs by offering a wide range of sizes and configurations tailored for specific continuous spin applications and grinding precision. The end goal is always the same: superior results, shorter lead times, and greater flexibility. Investing in rotary grinding tables means streamlining workflow, reducing waste, and equipping teams with the latest roto technology for demanding tasks.

Comparison Table: Key Features of Rotary Table vs. Rotary Grinding Table vs. Grinding Table |

|||

Feature |

Rotary Table |

Grinding Table |

Rotary Grinding Table |

|---|---|---|---|

Primary Function |

Rotational Positioning |

Flat Grinding Surface |

Rotational Grinding/Finishing |

Material Compatibility |

Metals, Plastics |

Metals, Ceramics |

Metals, Ceramics, Composites |

Tolerance |

High |

Medium-High |

Micron-Level |

Automation Ready |

Optional |

No |

Yes |

Ideal Use |

Indexing, Inspection |

Surface Finish |

Precision Surface, Complex Geometries |

Rotary Grinding Table Features: What Sets Them Apart

Rotary grind consistency

Material versatility—metals, ceramics, composites

Automation compatibility

Precision rotary grinding with micron-level tolerances

Heavy-load performance

Each rotary grinding table is an engineering marvel, designed to excel in rotary grind applications where ordinary machinery falls short. What makes these tables stand out? Their ability to maintain rotary grind consistency under changing loads ensures superb results, even for the toughest materials—be it titanium, hardened steel, or composite laminates. Their construction supports a wide range of materials, making them indispensable for companies operating across multiple industries.

Automation compatibility is another major advantage. Modern rotary grinding tables are built to integrate with robotic arms and automated production lines, vastly increasing throughput for high-volume operations. These tables feature micron-level precision rotary grinding, resulting in superior finishes and highly repeatable performance. With heavy-load performance capabilities, even the bulkiest engine or mold components are machined precisely—a critical asset for industries such as aerospace, automotive, and medical manufacturing.

"Precision rotary grinding tables have redefined component finishing, setting new standards for industrial efficiency." – Industry Expert

Precision Rotary Grinding Tables: Advanced Technologies and Innovations

Today’s precision rotary grinding tables are transforming manufacturing with integrated smart controls, real-time sensor feedback, and unparalleled grind precision. Manufacturers like Roto Tech and other industry leaders have introduced features like adaptive speed regulation, automated dressing systems, and hybrid rotary grind technologies to maximize productivity and protect both the table and tooling investment. Precision rotary grinding applications now leverage machine learning algorithms to dial-in optimal pressure and speed for every unique workpiece, pushing the boundaries of what’s possible on the shop floor.

Innovation extends beyond mechanical advancements. Precision rotary tables now include advanced HMI (human-machine interface) panels and IoT connectivity, empowering remote diagnostics and predictive maintenance. For manufacturers aiming to future-proof their operations and remain at the forefront of grind precision, these advances in rotary grinding table technology are invaluable. As global supply chains shift and automation deepens, the strategic importance of investing in such systems is only set to grow.

Emerging Trends: Precision Rotary & Automated Rotary Tables

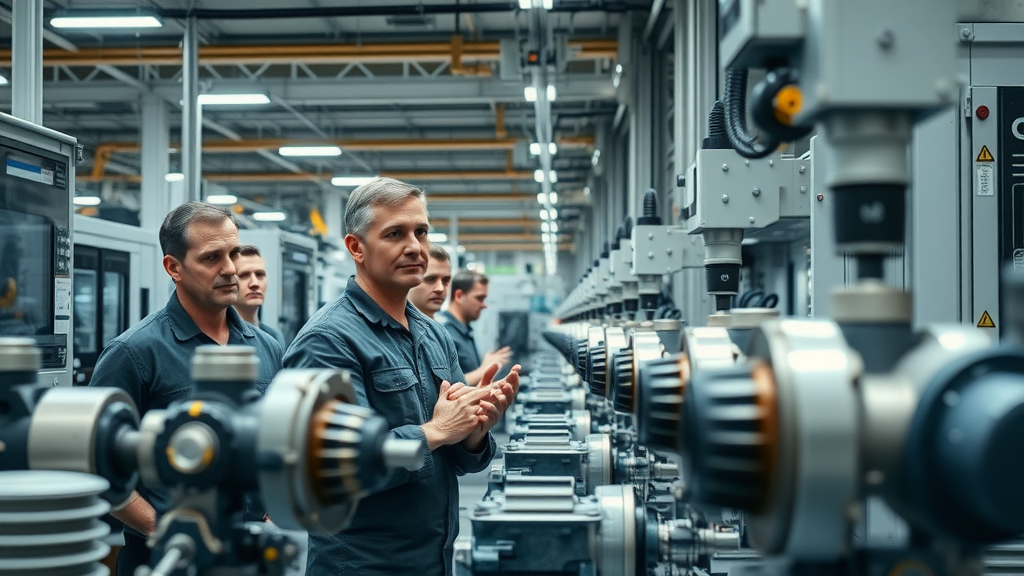

The rise of automated and smart rotary grinding tables signals a clear evolution in the market. Recent trends include the integration of autonomous robotic arms, precision rotary table synchronization, and adaptive tooling systems. These advancements offer continuous operation, reduced labor costs, and greater product consistency—a must for high-mix, high-volume industries. Automated inspection systems now work hand-in-glove with rotary grind equipment to detect minute defects, ensuring 100% compliance with customer specifications and industry standards.

As robo-driven manufacturing and digital twins gain popularity, manufacturers increasingly seek rotary tables capable of deep system integration and real-time data analytics. This shift not only boosts efficiency but also allows factories to flexibly shift between product lines, minimizing transition times between grinding applications. Companies using the latest rotary grinding tables report significant improvements in operational uptime and precision, solidifying their reputations as industry leaders.

Applications: Where Rotary Grinding Tables Deliver Maximum Value

Automotive: Engine and transmission components

Aerospace: Turbine blade finishing

Medical: Orthopedic and implant manufacturing

Tooling: Dies and molds

Rotary grinding tables are the foundation of excellence in sectors that demand absolute perfection. In automotive factories, these tables streamline engine block and transmission component finishing, increasing output while maintaining strict tolerances. Aerospace manufacturers rely on rotary grind precision to finish turbine blades and other flight-critical components, ensuring both safety and performance.

In medical manufacturing, the stakes are even higher—orthopedic implants, bone screws, and surgical tools must boast flawless surfaces to meet regulatory standards. Rotary grinding tables provide superior results in both mass production and custom runs. Toolmakers, meanwhile, use these tables to create dies and molds with long-lasting durability and supreme finish quality. With such a wide range of grinding applications and the ability to tailor grind operations for any sector, rotary grinding tables have become the go-to investment for manufacturers looking to stay ahead.

How to Choose the Right Rotary Grinding Tables: Buyer’s Tips

Assessing load capacity and table size

Evaluating precision rotary grinding tolerances

User interface and automation

Supplier support and warranty

Choosing the right rotary grinding table starts with understanding your unique application needs. First, assess required load capacity and table size; larger engine components or heavy molds demand robust configurations, while thinner medical parts might require compact, high-speed models. Next, prioritize grind precision rotary grinding tolerances. Does your production environment require micron-level accuracy, or is standard tolerance acceptable? Investing in a model with advanced feedback systems, such as those found in leading roto tech solutions, can ensure consistent results even as production demands fluctuate.

Consider the user interface—modern touch panels, automation integration, and remote operation options should be high on your checklist. Last but not least, evaluate the supplier’s reputation for support and warranty. Reliable after-sales service, quick access to spare parts, and options for remote diagnostics can minimize unplanned downtime. Whether you’re exploring a wide range of sizes and configurations or focusing on specific continuous spin applications, making an informed decision on your next rotary grinding table is an investment in both current performance and future growth.

Real-World Reviews: Customer Experiences with Rotary Grinding Tables

"Switching to a rotary grinding table cut our production time by 25%—an undeniable game-changer." – Operations Manager, Manufacturing Industry

Feedback from real-world users speaks volumes about the impact of rotary grinding tables. Manufacturing managers frequently tout reduced lead times, fewer product defects, and the versatility to tackle both small-batch custom work and large-scale production runs. Many mention how upgrading to rotary grinding tables enabled them to expand their product lines into new industries or take on more challenging projects without fear of compromising quality.

In repeated case studies, customers cite the robust performance of leading suppliers—like Roto Tech—as a major factor in their choice. Timely technical support, seamless automation integration, and the flexibility to accommodate a wide range of workpieces have all contributed to positive outcomes, further cementing the rotary grinding table’s status as a cornerstone of 21st-century machining excellence.

People Also Ask

What are rotary grinding tables used for?

Rotary grinding tables are specialized work surfaces used to precisely rotate components under a grinding wheel, ensuring high-quality surface finishes and tolerances. Integrated into production workflows, they excel in grinding complex shapes, delivering accuracy for parts in aerospace, automotive, and medical industries. Their adaptability across materials and part sizes makes them an invaluable asset for manufacturers aiming for consistent, superior results.

How do rotary grinding tables improve machining accuracy?

By ensuring consistent rotational movement, rotary grinding tables maintain tight tolerances and uniform finishes across complex shapes. This accuracy is vital when producing high-value components with exacting specifications. Advanced feedback controls help operators maintain grind precision, eliminating variables that can cause inconsistency or defects, thereby reducing waste and boosting overall production quality.

Can rotary tables be adapted for grinding applications?

Yes, many modern rotary tables are designed or can be upgraded for precision grinding operations, with added features for load management and fine adjustment. Manufacturers offer retrofit kits or purpose-built rotary grinding tables compatible with existing systems. This flexibility means facilities can leverage their current investments while moving toward advanced, precision rotary grinding applications.

FAQs: Rotary Grinding Tables

What maintenance do rotary grinding tables require?

Regular lubrication, periodic inspection of bearings, and timely replacement of wear components ensure peak performance. Modern tables often include alerts for proactive servicing and diagnostic tools for troubleshooting.How do rotary grinding tables compare in price to standard tables?

Rotary grinding tables typically cost more upfront than basic rotary tables or grinding tables due to advanced technology and enhanced precision. However, the productivity gains, superior results, and extended equipment life offer major long-term value.What industries benefit most from rotary grinding tables?

Industries needing exacting standards—such as automotive, aerospace, medical device, and tooling—find the unmatched precision and versatility of rotary grinding tables invaluable for staying competitive.

Key Takeaways: Why Invest in Rotary Grinding Tables?

Unmatched precision and repeatability

Versatile for various industries

Significant productivity improvements

Making Your Decision: Rotary Grinding Tables as a Strategic Investment

"Investing in advanced rotary grinding tables prepared us for future growth and innovation." – Manufacturing CEO

Ultimately, choosing a rotary grinding table is more than a simple purchase—it’s a step toward sustained competitive advantage, rapid innovation, and world-class quality. Leading organizations rely on precision rotary grinding tables to meet evolving market demands efficiently and confidently.

Ready to Take the Next Step with Rotary Grinding Tables?

Don't miss out! Call Roto Tech at 815-713-2305.

Subscribe to Global Trade News for Latest updates. Call 203-271-7991 today.

Integrating rotary grinding tables into your manufacturing process can significantly enhance precision and efficiency. For instance, Roto-Grind offers a range of precision rotary grinding tables designed for applications such as inside diameter, outside diameter, and surface grinding, as well as lapping, inspection, and assembly. Their models, available in sizes from 7” to 15” in diameter, are compatible with existing surface grinders, jig grinders, machining centers, milling machines, and EDM machines. (roto-techinc.com)

Exploring these resources will provide you with detailed insights into the features and benefits of rotary grinding tables, helping you make an informed decision to enhance your manufacturing capabilities.

Add Row

Add Row  Add

Add

Write A Comment