The Backbone of Modern Construction: Why Steel Framing Solutions Matter

Modern architecture and construction are pushing the boundaries of what once seemed possible. With increasing demand for buildings that last longer, perform better, and lend architectural flexibility, every material selected becomes critical. Traditional wood framing, despite its legacy, is often challenged by issues like decay, limited spans, and irregular performance. For people ready to invest in structures that not only meet, but exceed these new-age standards, the concept of steel framing solutions has become a central consideration.

Imagine the frustration of planning a commercial facility or industrial space, only to find the limitations of conventional materials slowing progress, increasing costs, or inviting maintenance headaches down the road. Steel framing, by contrast, is transforming the landscape with its remarkable structural integrity and adaptability. This isn't just a new trend; it’s a pragmatic response to enduring problems in the building industry. Understanding why steel framing solutions are radically changing expectations might be the deciding factor for anyone planning their next build or renovation project.

Steel Framing 101: The Engineered Edge Over Conventional Building

Steel framing solutions are setting new standards for construction across the world, blending engineering precision with time-tested strength. Unlike wood or masonry, steel resists warping, pests, and fire, making it extraordinarily reliable for commercial, industrial, and residential applications alike. The popularity of steel framing lies in its unique properties: minimal maintenance, consistent quality, and the capacity to support creative architectural designs without compromising safety. Pre-engineered metal building systems—an approach central to progressive firms—utilize meticulously calculated plans and state-of-the-art job cost software to guarantee accuracy and efficiency.

When architects and engineers discuss steel framing solutions, they’re not just talking about steel beams—they're referencing an entire system engineered to reduce project risks and lifecycle costs. From the precision of structural components to the flexibility of design, steel framing’s impact is far-reaching. Neglecting to consider this modern approach can leave property owners perpetually stuck in reactive maintenance or dealing with design limitations that hinder growth. That’s why understanding the fundamental benefits and potential of steel frames isn’t just desirable, it’s essential for making well-informed construction choices today.

How Steel Framing Solutions Shape Quality, Service, and Flexibility in Every Build

Leading construction firms, such as De Baise Construction Co Inc, demonstrate that expert application of steel framing solutions brings tangible value to clients looking for lasting strength and efficiency. With more than 20 years of hands-on field experience and an integrated team of architects, engineers, and project managers, these specialists leverage advanced design and estimating tools to deliver outstanding quality and adaptable solutions in every project. This deliberate pairing of technology and seasoned expertise ensures that steel framing isn't just structurally sound, but also perfectly tailored to each client's vision.

Clients benefit far beyond basic durability. The unwavering strength of steel offers robust resistance to environmental threats and reduces the long-term costs of ownership. Furthermore, steel framing’s inherent flexibility allows for open, customizable layouts—critical for businesses and industries evolving with market demands. By employing steel framing solutions, forward-thinking organizations sidestep costly delays, gain better control over project budgets, and realize faster, more efficient builds without sacrificing quality or design intent.

Steel Framing in the Evolution of Industrial and Commercial Construction

The rise of steel framing solutions has fundamentally changed how industrial and commercial spaces are conceived, built, and maintained. Structures once limited by traditional materials now embrace large open spans, intricate façades, and enhanced load-bearing capacities—making possible everything from state-of-the-art warehouses to highly efficient manufacturing plants. Coupled with metal roofing and pre-engineered buildings, the steel framing approach has moved from an alternative to a preferred standard, particularly when businesses or property owners seek both aesthetic and operational advantages.

Steel framing's design flexibility means engineers and architects can collaborate more freely, incorporating practical and creative visions into a single, seamless structure. For industrial facilities with specialized needs—such as custom foundation work, precise masonry, or specialized metal repairs—integrating steel framing ensures compatibility across all project stages. This creates a comprehensive building solution that meets today’s demands while offering scalability for tomorrow.

Building for the Future: Why Expertise in Steel Makes All the Difference

As sustainability, resource optimization, and lifecycle performance draw more focus in the construction industry, steel framing solutions emerge as a frontrunner for future-ready design. The push towards pre-engineered buildings and eco-efficient development is more than a trend; it’s a necessity rooted in the principles of quality, safety, and environmental stewardship. Steel’s recyclability, combined with precise engineering, means projects can achieve both green goals and operational targets, supporting a smarter built environment.

What ultimately sets a successful steel-framed project apart is the caliber of professional oversight guiding the process. Deep knowledge in metal building systems, advanced cost estimation, and flexible project management all contribute to smoother builds and greater owner satisfaction. By aligning with specialists who value quality and service above all, project owners ensure every steel framing solution is both a technical and practical asset—today and into the future.

From Vision to Reality: A Professional Approach Grounded in Collaboration

De Baise Construction Co Inc exemplifies a philosophy centered around delivering quality, service, and flexibility in every steel framing project. With a team that includes architects, engineers, and project managers, the process is highly collaborative—each project begins by truly listening to client needs. This commitment is visible from the earliest design phases, where state-of-the-art estimating and design software bridges client concepts with field-tested expertise. The result is steel framing that supports not only the structural integrity of the building, but also the operational goals and growth expectations of the client.

What distinguishes their approach further is adaptability. By specializing in pre-engineered metal building systems, the team at De Baise ensures that every project, whether it demands custom foundations, innovative layouts, or complex metal repairs, is delivered with robust precision. Their reputation is built upon decades of practical experience combined with a modern outlook—demonstrating that intelligent application of steel framing means every vision can become reality, without compromise.

How a Thoughtful Steel-Framed Build Transforms Business: Real-World Success

Choosing to invest in steel framing is not just about the physical strength of materials, but about bringing a vision to life in a way that maximizes long-term value and utility. One client recently described their journey transitioning a growing custom manufacturing operation into a new, steel-framed facility. This review, rooted in experience, reflects why so many businesses view the right construction partner as a catalyst for transformation.

I knew that for my business to grow, I needed additional and more efficient space for my custom countertop manufacturing operation. After meeting with various contractors, I finally met with DeBaise Construction. During the initial meeting Steve already had a handle on my needs and began to make sound suggestions, which were ultimately made part of the final design. From the design phase, through the planning and zoning approvals and ultimately the construction, DeBaise Construction proved to be the right company for my project. R. Teixeira

Stories like these underscore the deep trust and appreciation business owners have when their practical and long-term needs are truly understood. Investing in steel framing solutions often marks a pivotal step in operational success—yielding not only improved spaces, but smoother processes and more confident planning for years to come.

Steel Framing Solutions as the Cornerstone of Sustainable, Flexible Construction

In today’s competitive marketplace, steel framing solutions are quickly becoming the cornerstone of efficient, future-ready building strategies. The expertise and philosophy of firms like De Baise Construction Co Inc play a vital role in advancing construction quality across communities, transforming what’s possible for both large-scale developments and smaller specialized builds. Ultimately, selecting steel framing solutions represents more than a material choice—it’s an investment in structural excellence, longevity, and architectural freedom for every type of client or project.

Whether designing a new industrial plant, expanding a business facility, or considering ways to cut long-term maintenance costs, understanding the potential of steel framing solutions has never been more crucial. Its combination of durability, customizability, and expert-driven implementation will continue elevating standards for what modern construction can and should be.

Contact the Experts at De Baise Construction Co Inc

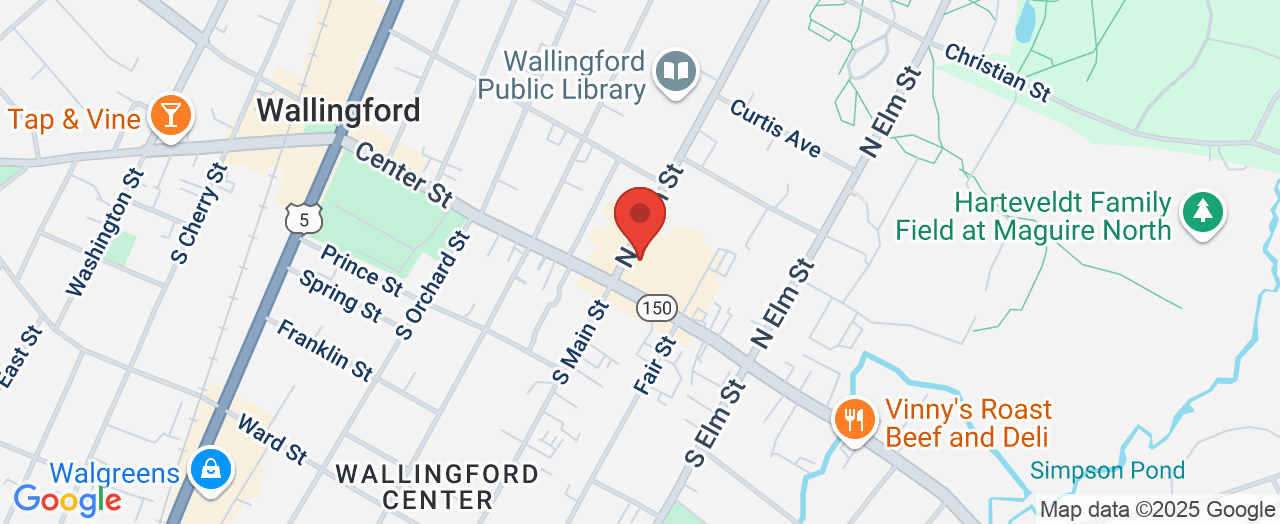

If you’d like to learn more about how steel framing solutions could benefit your next construction project, contact the team at De Baise Construction Co Inc. 📍 Address: 33 N Main St, Wallingford, CT 06492 📞 Phone: +1 203-284-1603 🌐 Website: http://debaise.com/

De Baise Construction Co Inc Location and Availability

🕒 Hours of Operation:📅 Monday: 7:00 AM – 5:00 PM📅 Tuesday: 7:00 AM – 5:30 PM📅 Wednesday: 7:00 AM – 5:00 PM📅 Thursday: 7:00 AM – 5:00 PM📅 Friday: 7:00 AM – 5:00 PM📅 Saturday: ❌ Closed📅 Sunday: ❌ Closed

Add Row

Add Row  Add

Add

Write A Comment