Did you know that over 70% of leading manufacturers now rely on non-contact automated gaging to boost product quality and reduce waste? This remarkable shift highlights the new era of advanced quality control—where precision and efficiency aren’t options, but expectations. Today’s manufacturing world demands measurement solutions that keep up with rapid throughput, critical dimensions, and global trade shifts. Whether you're overseeing a production line or evaluating your next technological upgrade, understanding how non-contact automated gaging powers results can make the difference between lagging behind and leading the industry. Dive in to discover how you can elevate your process with next-generation gauging systems for measurable ROI.

"Over 70% of leading manufacturers now rely on non-contact automated gaging to boost product quality and reduce waste."

How non-contact automated gaging revolutionizes inspection

Key differences between non-contact and contact gauging

How leading systems like Six Sigma Concepts navigate global trade impacts

Criteria to select the best automated gauging system for your process

Answers to top industry questions about non-contact measuring technology

A Game-Changer: Non-Contact Automated Gaging and the Future of Quality Control

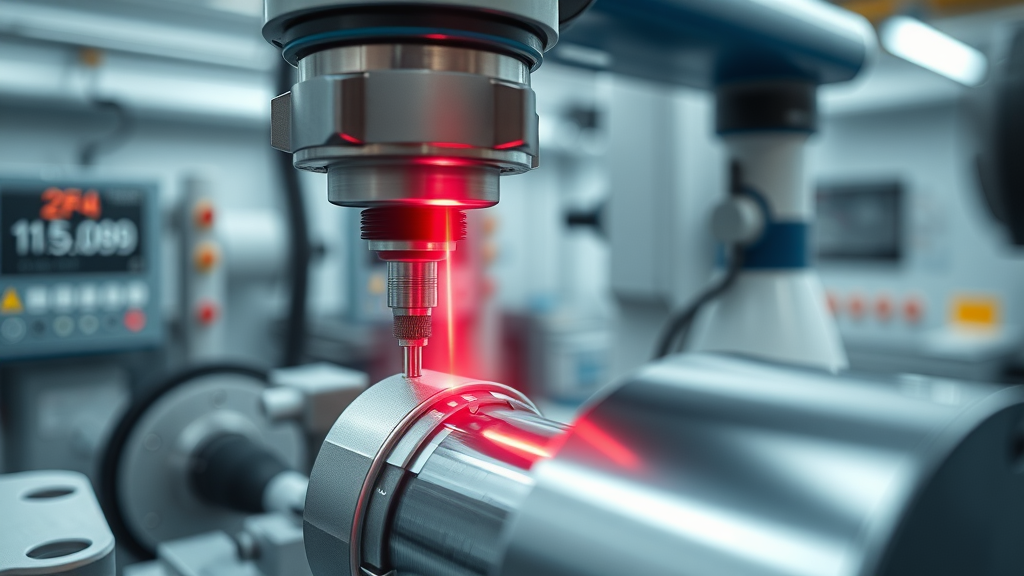

When it comes to quality control, non-contact automated gaging is rewriting the rulebook for factory environments across the globe. Unlike traditional contact gauging that can slow production lines and introduce wear, non-contact systems use lasers, vision, and sensors to inspect critical dimensions with incredible speed and accuracy. This leap is driving measurable improvements in output, consistency, and cost-efficiency for manufacturers striving to stay ahead of global competition and evolving regulatory standards.

Automated gauging systems—especially those featuring inline gaging—integrate seamlessly into existing manufacturing process workflows and deliver real-time checks at every stage. As the global supply chain faces pressures from tariffs and reshoring, companies are leaning on non-contact automated gaging to navigate uncertainty and enforce compliance with stringent industry standards. By leveraging automated inline gaging, manufacturers don’t just detect problems—they prevent defects and enable smarter process control, ultimately delivering fast, accurate results that keep customers satisfied and businesses thriving. Investing in automated gauging is more than a quality control upgrade; it’s a strategic move that offers scalability and future-proofs your operations against industry disruption.

What Is Non-Contact Automated Gaging? Defining Next-Generation Gauging Systems

Non-contact automated gaging refers to systems that use lasers, machine vision, and advanced sensor technology to measure part physical dimensions without touching the workpiece. Unlike legacy contact thread and mechanical devices, these innovative systems feature precision and speed, reducing manual errors and measurement variation common in traditional gauging systems. The result? Highly accurate monitoring, measurement, and data collection during production, ensuring process control and minimizing the risk of defective parts entering downstream operations.

How Non-Contact Automated Gaging Works Within Modern Gauging Systems

In a high-tech production environment, non-contact automated gauging works by integrating various sensing modalities—laser micrometers, optical comparators, and vision systems—to measure components as they flow through the production line. Each sensor transmits and analyzes beams or images, instantly interpreting dimensions, form, and even surface finish. All of this information is relayed to a central quality lab or control company software, allowing operators to track trends, spot deviations, and make immediate, data-driven adjustments. Unlike conventional methods that slow down throughput or require costly human inspection, these modern gauging systems automate precise measurement at high speed, minimizing downtime and human error. The systems that deliver fast, accurate results are specifically designed for the rigorous demands of today’s manufacturing environment, keeping production lines moving and reputations intact.

Automated Gauging Systems Versus Contact Gauging: Key Differences

Traditional contact gauging relies on probes or mechanical devices making direct contact with parts—a method still in use for certain applications but increasingly outpaced by the accuracy and speed of automated gauging systems. With contact gauging, there’s an inherent risk of marking or deforming delicate surfaces, potential delays due to probe maintenance, and limitations in measuring complex geometries. Conversely, non-contact automated gaging eliminates direct contact, allowing for inspection of intricate shapes, flexible materials, or high-volume parts without wear or tear on equipment. The shift to automated gauging means improved consistency, less operator intervention, and more comprehensive dimensional data for every part. For specialized needs like contact thread verification or parts with challenging critical dimensions, modern gauging system designs provide both traditional and non-contact options to cover the full measurement spectrum.

Dimensional Gauging: Advancements with Non-Contact Sensors

Dimensional gauging with non-contact sensors is at the core of modern process control and quality optimization. These sensors—ranging from laser displacement devices to high-resolution optical cameras—measure physical dimensions instantly and precisely, even as parts move at speed. What distinguishes non-contact solutions is their ability to take multiple readings per second, process real-time data, and feed actionable insights straight into control systems or automated inline workflows. Whether verifying thread geometry, part diameter, or overall surface profile, these systems ensure each product meets exacting tolerances without manual checks, supporting both mass production and custom part manufacturing with equal efficiency.

Core Features and Benefits of Non-Contact Automated Gauging Systems

Inline Gaging for Real-Time Quality Control: Instantly detect errors and deviations as parts move through the line, cutting waste and costly delays.

Automated Inline Gaging Enhances Efficiency: Maintain continuous throughput and reduce bottlenecks with no slowdowns for manual checks.

Versatility for Multiple Part Types: Adapt quickly to changing production needs, from tiny components to large assemblies—no need for separate setups.

Minimal Maintenance & Downtime: Non-contact sensors don’t wear; systems require only occasional calibration, maximizing uptime.

Scalability for Various Production Volumes: Handle both low and high-volume runs with consistent, repeatable accuracy—critical for expanding operations.

Comparing Gauging System Types: Automated Gauging System, Contact Thread, and More

Comparison of Automated Gauging Systems vs. Contact Gauging Methods |

||

Criteria |

Automated Non-Contact Gaging |

Contact Gauging |

|---|---|---|

Accuracy |

Highly accurate, repeatable, ideal for complex and delicate parts |

Good, but subject to mechanical wear and probe deformation |

Speed |

Real-time, high throughput—enables inline gaging during production |

Slower, requires physical contact and repositioning time |

Maintenance |

Minimal, mostly sensor calibration, no moving parts in contact |

Frequent, due to probe wear and calibration needs |

Operational Cost |

Lower over time due to fewer manual interventions and less downtime |

Higher—more labor, replacement parts, and downtime |

Selecting the Right Non-Contact Automated Gaging for Your Operations

Choosing the right non-contact automated gauging system for your manufacturing process requires considering part types, required tolerances, expected production volumes, and integration needs. Begin by mapping out your process flow and identifying where inline gaging can prevent costly defects. Evaluate the versatility of available systems—can they handle complex geometries, perform thread verification, and easily scale with growth? Look for features like real-time data analysis, minimal manual intervention, and compatibility with your existing control company infrastructure. And remember: reliable supplier support and trained technical staff are just as important as the hardware itself for maintaining uptime in high-stakes production environments. The best automated gauging system is one that aligns with your current needs and provides flexibility for future expansion or new product lines.

Inline Gaging and Automated Inline Integration Strategies

To maximize quality and output, integrating automated inline gaging at critical junctures of your production line is essential. Modern manufacturers implement inline sensors right after key operations—such as drilling, turning, or assembly—so every part is measured the moment it’s made. Data from these systems is streamed instantly to dashboards or process control software, providing a transparent, real-time window into quality lab performance. This approach not only safeguards against passing defects along the line, but also empowers operators to make adjustments proactively, before minor issues become major production halts. Automated inline gaging supports lean manufacturing initiatives, validating each step without bottlenecks or additional labor, and ensures you consistently deliver parts and components that exceed customer requirements.

Automated Gauging System Considerations: Software, Sensors, and Support

When seeking an automated gauging system, don't just focus on sensors—consider the role of intuitive software, integration flexibility, and responsive technical support. Leading gauging systems feature powerful analytics tools to detect trends, visualize results, and automate reports for compliance or audits. Check if the system supports customizable parameters and is user-friendly for both new operators and seasoned technicians. For sensors, verify they can measure the full range of your parts and withstand demanding factory environments. Finally, partner with providers who offer comprehensive support—from initial installation to long-term calibration—so you have the expertise to deliver on even the most challenging production cycles. With these considerations, your investment in non-contact automated gaging becomes a cornerstone of process control and repeatable, top-tier manufacturing outcomes.

Case Study: How Six Sigma Concepts Thrives with Non-Contact Automated Gaging

When the global supply chain landscape shifted, Six Sigma Concepts invested in non-contact automated gaging to ensure product compliance and precision across its international facilities. With complex regulatory demands and high-volume output, their adoption of advanced automated gauging systems—including inline and automated inline gaging—transformed their approach to quality control. By integrating multi-sensor modules and real-time data dashboards, Six Sigma Concepts proactively detected subtle process deviations, reduced material waste, and maintained compliance despite changing tariffs and shipping constraints. Their experience and expertise in deploying the right gauging system for each unique operation stand as proof that the right non-contact solution can safeguard both your brand reputation and your bottom line—even in unpredictable times.

"Navigating the shifting global supply chain, Six Sigma Concepts leverages non-contact automated gaging to ensure precision and compliance across multinational facilities."

People Also Ask: Insights into Non-Contact Automated Gaging Systems

What is an example of a non-contact measuring instrument?

Laser micrometers, optical comparators, and machine vision inspection systems are all non-contact measuring instruments integral to advanced gauging systems. They enable manufacturers to measure part dimensions at speed and with unparalleled accuracy, even for intricate or moving components. These instruments are often deployed on production lines for automated quality control, making them a staple in the world of non-contact automated gaging.

Which is an example of a non-contact sensor?

Examples include laser displacement sensors, capacitive sensors, and machine vision cameras. These non-contact sensors are commonly found in automated gauging systems, where they measure size, shape, and other physical attributes without touching the part. Their precision and durability make them ideal for continuous, reliable operation in factory environments.

What is the difference between contact and non-contact sensors?

Contact sensors require physical touch with the measured object, which can slow operations and wear out over time. In contrast, non-contact sensors use light, sound, or electromagnetic fields to measure from a distance, minimizing part distortion and maximizing accuracy—especially crucial for high-speed automated gauging.

What is a non-contact level measurement?

Non-contact level measurement determines material height or volume in containers using radar or ultrasonic waves. This technology is essential in quality control and inventory management, as it enables rapid, contamination-free measurement of liquids, powders, or bulk goods—key for both automated gauging and process monitoring in modern manufacturing.

FAQs: Non-Contact Automated Gaging and Modern Gauging Systems

How does non-contact automated gaging improve quality control?

By providing real-time, inline measurement of every part, non-contact automated gaging quickly identifies deviations, prevents defects, and reduces the need for costly rework—all while maintaining high throughput in production lines.Can automated gauging systems handle custom part types?

Yes! Today’s non-contact systems are designed for versatility, adapting to a wide variety of part shapes, sizes, and materials without the need for manual tool changes or time-consuming adjustments.What industries benefit most from non-contact automated gaging?

Industries with stringent quality requirements, including automotive, aerospace, medical device manufacturing, and electronics, see significant cost savings and compliance assurance from advanced gauging systems.How does inline gaging fit into today’s manufacturing workflows?

Inline gaging integrates directly with automated production and assembly lines, providing continuous quality checks and live feedback, so any issues are caught early—boosting efficiency and reliability across the entire manufacturing process.

Key Takeaways: Elevating Quality with Non-Contact Automated Gaging

Non-contact automated gaging drives next-level quality, efficiency, and scalability.

Flexible integration is possible for diverse manufacturing setups.

Real-world examples prove measurable ROI and compliance benefits.

Ready to Transform Your Quality Control? Get the Latest on Non-Contact Automated Gaging

-

Don't miss out! Call Six Sigma Concepts at 413-935-1885.

Subscribe to Global Trade News for the latest updates. Call 203-271-7991 today.

Transform your process control—contact us today and unlock the full potential of non-contact automated gaging!

Add Row

Add Row  Add

Add

Write A Comment