Did you know that 72% of the active pharmaceutical ingredients used in U.S. drugs are sourced overseas? This staggering dependency puts the safety and quality of our most crucial drug products at risk. Disruptions in a global supply chain can create drug shortages, heighten public health threats, and limit oversight for pharmaceutical manufacturing. As the movement to reshore pharmaceutical manufacturing gains momentum across the United States, understanding the pharmaceutical reshoring benefits is more than just an industry trend—it's a strategic imperative for safer, higher-quality drug products and greater supply chain security. Let's examine why bringing drug manufacturing back home could be the key to a safer and more resilient future for patients and pharmaceutical companies alike.

A Startling Look at Pharmaceutical Reshoring Benefits

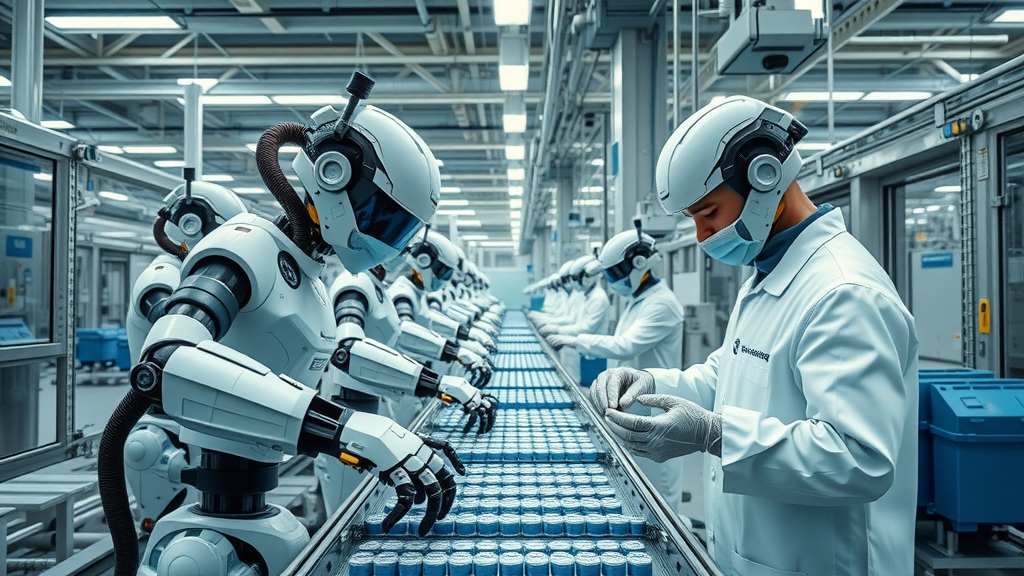

The historic reliance on overseas suppliers has profoundly shaped the current pharmaceutical landscape. With 72% of active pharmaceutical ingredients (APIs) used in U.S. drug products sourced from countries like China and India, the implications for drug safety and supply chain reliability cannot be overstated. Major disruptions—from geopolitical changes to raw material shortages—can quickly ripple through the global supply chain, catalyzing drug shortages that affect patients and public health systems in the United States. Reshoring pharmaceutical manufacturing isn't simply about reducing labor costs or responding to the latest federal government policy; it represents a critical pivot to better control product quality, batch manufacturing, and active oversight. By investing in domestic production capabilities, pharmaceutical companies and manufacturers equip themselves with greater flexibility, increased traceability, and the tools to address emerging threats with speed. This transformation, built on the momentum of recent policy and market trends, will not only bolster supply chain security but also redefine what it means to develop the safest, highest-quality drug products for the U.S. market and beyond.

From a regulatory standpoint, reshoring pharmaceutical manufacturing can vastly improve compliance and streamline communication with oversight agencies like the FDA. Ensuring that drugs meet stringent U.S. safety standards is far easier when manufacturing sites are local, offering real-time quality checks and swifter response to any issues. Beyond compliance, the transition to domestic manufacturing could resolve long-standing issues with generic drug shortages, unlock advanced manufacturing technologies, and build robust pharmaceutical supply chains resilient to both global and local disruptions. As the industry embraces these pharmaceutical reshoring benefits, the conversation must remain grounded in both the economic realities and the unwavering commitment to safer drugs.

What You'll Learn About Pharmaceutical Reshoring Benefits

The critical advantages of pharmaceutical reshoring benefits for safety and quality

How reshoring pharma enhances supply chain security and reliability

The economic, regulatory, and ethical implications of reshoring pharmaceutical operations

Expert and industry opinions shaping the debate on pharmaceutical manufacturing

Pharmaceutical Reshoring Benefits: Defining the Trend

Understanding Pharmaceutical Reshoring and Drug Manufacturing

Pharmaceutical reshoring refers to the movement of bringing drug manufacturing operations—covering the entire spectrum of API, batch manufacturing, and drug product assembly—back to the United States from overseas. This trend is spurred by recognition of vulnerabilities within the global supply chain, the high dependency on foreign manufacturers, and historical lessons from pandemic-related drug shortages. Not long ago, many pharmaceutical companies were drawn abroad by promises of lower labor costs and vast manufacturing capacities, but the risks posed by distance and lack of oversight have become impossible to ignore.

The story of pharmaceutical manufacturing is entwined with developments in global markets, regulatory policies, and shifting economic priorities. The drive for profit once led companies to build manufacturing facilities in countries known for cheaper raw materials and labor. But today, reshoring pharma is seen as a means to improve drug quality, meet regulatory requirements, and safeguard national public health. The federal government, heeding warnings about supply chain fragility, has ramped up support for reshoring initiatives, while manufacturers are exploring investments in advanced manufacturing technologies that promise both efficiency and better quality control.

Reasons for Reshoring Pharma Operations

The movement to reshore pharmaceutical manufacturing has gained traction for several compelling reasons. The most pressing is the need for stronger oversight over supply chains, which are increasingly vulnerable to delays, disruptions, and contamination when APIs and finished drugs rely on the global supply network. Events such as pandemics, geopolitical conflicts, and international transportation breakdowns have shown that placing pharmaceutical manufacturing too far from home endangers both drug product availability and quality.

Additionally, regulatory compliance is much easier to monitor within the United States. Domestic production allows for face-to-face inspections, immediate corrective actions, and stringent batch manufacturing documentation; these factors bolster public trust and improve the overall reliability of the pharmaceutical supply chain. Growing bipartisan support for bringing manufacturing back has led to increased funding for pharmaceutical companies and the development of new policies designed to incentivize investments in U.S.-based pharmaceutical manufacturing capabilities and infrastructure.

Major Pharmaceutical Reshoring Benefits for Drug Product Safety

Comparison of Drug Product Quality: Overseas vs. Domestic Manufacturing |

||

Aspect |

Overseas Manufacturing |

Domestic Manufacturing |

|---|---|---|

Supply Chain Risk |

Higher (subject to international delays, raw material shortages) |

Lower (more predictable, better transparency) |

Regulatory Oversight |

Indirect, less frequent inspections |

Direct, continuous inspections and compliance |

Quality Control |

Variable, often less stringent standards |

Strictly monitored, higher consistency |

Response to Drug Shortages |

Slower; dependent on international logistics |

Rapid, flexible manufacturing capacity |

National Security |

Potential vulnerabilities from foreign dependency |

Greater resilience, aligned with national interests |

Reduced Risk in the Pharmaceutical Supply Chain

One of the most significant pharmaceutical reshoring benefits is the reduction of risk in the pharmaceutical supply chain. When key ingredients and finished drug products must traverse complex global supply routes, the possibility of disruptions grows exponentially. Issues ranging from transportation delays to export restrictions in supplier countries can suddenly halt production of essential medicines, triggering both drug shortages and dangerous gaps in patient care. By reshoring pharma manufacturing, companies regain control over logistics, reduce exposure to overseas hazards, and achieve unparalleled traceability—from raw materials sourcing to drug product delivery—within domestic borders.

This increased control translates to faster detection and resolution of quality issues. Domestic manufacturing operations mean that pharmaceutical ingredients and finished drugs can be tracked in real-time, vulnerabilities are quickly addressed, and regulatory agencies can respond immediately to any potential threats. With these enhancements, pharmaceutical companies can fortify the backbone of their supply chains, ensuring that patients receive safe, effective medicines precisely when needed, and reducing the risk of widespread drug shortages that threaten public health.

Improved Quality in Drug Manufacturing and Oversight

Domestic pharmaceutical manufacturing promises greater consistency in oversight and adherence to the highest U.S. safety and quality standards. Unlike international facilities that may operate under varying interpretations of standards, manufacturing sites in the United States are closely monitored by agencies like the FDA. This close proximity ensures rapid communication during regulatory audits, transparent batch manufacturing records, and the swift implementation of corrective actions, greatly improving the reliability of the pharmaceutical supply chain.

Enhanced transparency not only bolsters patient safety but also nurtures public confidence in pharmaceutical companies. Advanced manufacturing technology, adopted more rapidly at home, further supports real-time quality checks, data-driven decision-making, and the ability to scale manufacturing capabilities to meet shifting demand. Pharmaceutical reshoring benefits thus drive a robust, responsive, and trustworthy system capable of adapting to future challenges while upholding the highest standards for every drug product.

Economic and Societal Impacts of Reshoring Pharma

Reshoring Pharmaceutical Manufacturing and Job Creation

Pharmaceutical reshoring benefits are not limited to drug quality and safety—they extend to substantial economic and societal gains as well. Returning high-value drug manufacturing and pharmaceutical supply chain management to American soil stimulates new job opportunities, particularly in biotechnology and advanced manufacturing. The need for a skilled workforce—from research scientists to manufacturing technicians—fuels employment across regions, infusing local economies with stable, high-wage positions and revitalizing communities that may have experienced industrial decline.

These advantages also contribute to a pipeline of talent in STEM (science, technology, engineering, and mathematics) fields, ensure ongoing education and training, and create pathways for career growth. Pharmaceutical companies investing in U.S.-based manufacturing facilities find themselves not only boosting productivity but also building long-term social equity and economic resilience. In an era of global uncertainty, prioritizing domestic production can help stabilize local economies, expand the tax base, and improve overall public health infrastructure through reliable access to essential drug products.

Long-term Economic Advantages of Pharmaceutical Reshoring Benefits

While the up-front investments in reshoring pharmaceutical manufacturing may be significant—including capital for new facilities, workforce training, and process innovation—the long-term economic returns can be tremendous. Stateside manufacturing strengthens domestic supply chains, encourages technological advancement, and increases the nation’s manufacturing capacity. The result is a more sustainable industry, less vulnerable to external shocks or foreign policy changes.

Pharmaceutical reshoring also addresses strategic concerns about national security, making the United States less dependent on other nations for vital drug products. Effective domestic manufacturing capacity can mitigate the risk of drug shortages, ensure that manufacturing sites are prepared for emergencies, and provide the flexibility needed to ramp up production for unanticipated public health needs. Over time, these structural improvements lay the groundwork for ongoing leadership in pharmaceutical innovation and robust economic growth across the sector.

Challenges and Drawbacks of Pharmaceutical Reshoring

Potential Drawbacks in Domestic Manufacturing Capabilities

Despite the compelling pharmaceutical reshoring benefits, there are critical challenges that must be carefully considered. Establishing or expanding domestic manufacturing facilities often requires significant financial investment, from acquiring advanced manufacturing equipment to upgrading existing sites and maintaining compliance with all regulatory standards. Labor costs in the United States are higher than those in many traditional pharmaceutical exporter countries, which can put pricing pressure on drug products, particularly generic drug segments.

Additional hurdles include the need for ongoing workforce development, as the skills required for modern pharmaceutical manufacturing differ from traditional manufacturing roles. Building a robust talent pipeline will be essential for scaling up domestic production and maintaining high standards of quality and efficiency. Finally, coordination between federal government stakeholders, regulatory agencies, and private pharmaceutical companies is critical to streamline processes and ensure that investments yield sustainable long-term gains across the pharmaceutical sector.

Balancing Benefits and Risks in Drug Manufacturing Reshoring

Finding the optimal path forward means weighing the undeniable benefits of pharmaceutical reshoring against its logistical, regulatory, and financial challenges. For many companies, this process requires careful strategic planning—balancing costs with the potential for long-term savings, enhanced supply chain security, and higher brand equity. The requirement for greater domestic manufacturing capacity calls for both private and public investment, a commitment to ongoing innovation, and an openness to policy reform that rewards domestic production without stifling competition or accessibility.

As Aristotle once proclaimed, "Quality is not an act, it is a habit." For the pharmaceutical industry, this means viewing reshoring as not just a short-term solution to overseas risks but as an enduring commitment to excellence, safety, and public trust.

Key Opinions: Industry Leaders on Reshoring Pharmaceutical Manufacturing

Pharmaceutical manufacturers emphasize that investing in domestic facilities ensures greater regulatory compliance, a faster response to emergencies, and the flexibility to adapt to changing market or public health needs.

Policymakers argue that reshoring the pharmaceutical supply chain is vital for national health security, reducing reliance on unpredictable overseas markets, and enhancing public transparency.

Experts in drug manufacturing stress that innovation and advanced manufacturing techniques, when implemented close to home, result in higher quality and more reliable drug products, thereby safeguarding both the industry and the communities it serves.

Case Studies: Pharmaceutical Reshoring Initiatives

Several recent reshoring initiatives illustrate the real-world pharmaceutical reshoring benefits for supply chain resilience and drug product safety. For example, a leading U.S. pharmaceutical company recently opened a new advanced manufacturing site, doubling its domestic production of generic drugs and critical active pharmaceutical ingredients. As a direct result, regional hospitals noted fewer disruptions in medicine supply and more reliable access to high-demand drug products during crises. Elsewhere, state governments have partnered with pharmaceutical companies to co-fund new manufacturing facilities, leveraging local resources and training programs to speed up onboarding and production. These successes serve as models for how collaboration, investment, and policy support can generate lasting improvements in the U.S. pharmaceutical manufacturing landscape.

Watch: How Reshoring Improves Pharmaceutical Safety and Supply Chain Security

Lists: Top Pharmaceutical Reshoring Benefits at a Glance

Shorter supply chains reduce disruption risks

Greater control over quality standards

Strengthening national public health security

Enhanced responsiveness in emergencies

Job creation in biotechnology and manufacturing sectors

FAQs on Pharmaceutical Reshoring Benefits

What is the purpose of reshoring?

Reshoring aims to bring manufacturing processes, such as drug manufacturing, back to the company's home country. The primary goals are to enhance supply chain security, elevate product quality, and boost economic growth by fostering domestic manufacturing capabilities and reducing reliance on the global supply chain.

What are some of the potential benefits and drawbacks of reshoring or nearshoring manufacturing operations?

Key benefits include improved domestic manufacturing capabilities, increased job opportunities, and enhanced oversight for safer drug products. However, drawbacks may involve higher initial costs for infrastructure, the need for skilled workforce training, and possible delays during the transition as domestic facilities scale up to meet growing demand.

What are the benefits of pharmaceutical advertising?

Pharmaceutical advertising educates patients and healthcare providers about new or existing drug products, supporting better health outcomes. However, it must be balanced with ethical marketing practices to maintain public trust and ensure the accurate dissemination of medical information.

What would be a reason for a company to utilize reshoring?

Companies may choose to reshore their pharmaceutical manufacturing to reinforce the strength and traceability of their supply chain, respond to evolving regulatory requirements, or achieve a competitive advantage by offering high-quality, reliably produced drug products for domestic and export markets.

Key Takeaways: Pharmaceutical Reshoring Benefits

Pharmaceutical reshoring benefits can enhance supply chain security and product quality.

Domestic manufacturing strengthens economic resilience.

Strategic risks and costs should be carefully evaluated.

The industry is at a pivotal moment to redefine its manufacturing capabilities.

Conclusion: Reshoring Pharmaceutical Manufacturing for a Safer Future

The case for pharmaceutical reshoring benefits is rooted in ensuring drug safety, securing supply chains, and supporting domestic economies. Careful strategy, innovation, and policy coordination will be essential for realizing the full potential of this transformative trend.

Stay Informed: Harness Pharmaceutical Reshoring Benefits for Your Business

Manufacturer don't miss out! Stay informed on global trade shifts—tariffs, reshoring, and supply chain updates could reshape your strategy. Subscribe to Global Trade News for latest updates. Call 203-271-7991 today.

Add Row

Add Row  Add

Add

Write A Comment