-

A single shift in mineral tariff changes can increase raw material costs by over 15% overnight—forcing businesses to react quickly or risk severe losses. Why should this number matter to your operation? Discover how these mineral tariff changes are upending your trade strategies right now.

Mineral tariff changes are sending shockwaves through global supply chains and the markets for critical minerals . In days—sometimes overnight—a single tariff adjustment can raise raw material costs by more than 15%, directly impacting your bottom line. If your business depends on a steady flow of minerals or metals, failing to react to these sudden tariff rate shifts could put you behind your competitors or even push you out of the market entirely. Understanding these urgent changes is not just a matter of cost, but of survival. In this article, you’ll discover why these shifts matter, who’s at the controls, and what actionable strategies you must use to adapt today.

With new policies from the White House , international reciprocal tariffs , and growing concerns about national security , businesses worldwide are scrambling to understand and manage the new tariff landscape. Let's dive into the urgent details that will define your company's competitive edge in the evolving world of critical mineral supply chains .

Why Mineral Tariff Changes Are Redefining the Global Critical Mineral Supply Chain

-

Explore recent mineral tariff changes, their direct impact on supply chain efficiencies, and why you must monitor critical mineral regulations to maintain competitiveness.

-

What You'll Learn in This Article about Mineral Tariff Changes

-

• How mineral tariff changes disrupt mineral supply chains

-

• What market volatility means for critical minerals

-

• The geopolitical context—recent decisions by presidents and global leaders

-

• Practical strategies to shield your supply chain from unexpected tariff rate spikes

-

• Key statistics and future trends in reciprocal tariff battles

The global critical mineral supply chain operates on a razor’s edge. Mineral tariff changes don't just present accounting headaches; they fundamentally alter the cost, speed, and reliability at which manufacturers and technology companies secure essential resources. From rare earth elements that power your smartphone to metals crucial for electric vehicle batteries and global energy systems, these shifts can upend carefully calibrated supply chains overnight.

CEOs and supply chain professionals must now navigate a landscape where every new tariff rate or emerging reciprocal tariff policy could mean sudden price surges—or even the loss of critical suppliers. Notably, the increasing use of tariffs as a tool for national security and international leverage, especially by U.S. leaders like President Trump and the current administration, has raised both opportunity and risk for anyone importing minerals. Monitoring every regulatory change is now a competitive necessity; falling behind risks being priced out of production or losing precious market position.

Decoding Mineral Tariff Changes: How Recent Tariff Rate Adjustments Impact Critical Minerals

Current Tariff Rate Trends Affecting the Mineral Supply Chain

Today, the world’s major economies are engaged in a tariff rate tug-of-war, pushing costs higher along the mineral supply chains for businesses in the United States , Europe, and Asia. Recent increases in import tariffs —often jumping from single digits to over 20%—mean that manufacturers sourcing critical minerals such as lithium, cobalt, and rare earth elements are now facing a new paradigm of risk and expense. For instance, when one partner imposes a new 15% tariff, competing countries often retaliate with reciprocal tariffs, making it virtually impossible to rely on historically stable trade routes.

The pattern is clear: mineral tariff changes seldom come in isolation. Rather, they set off a global domino effect, with both established and emerging markets racing to protect domestic industries. As a result, the cost structure of everything from electric vehicle batteries to semiconductor chips is rapidly evolving. Businesses that once benefited from global access to affordable raw materials are now forced to adapt quickly or fall behind.

Market Volatility: How Mineral Tariff Changes Influence Critical Mineral Supply and Demand

Market volatility has become the defining characteristic of today’s critical mineral supply chains . Each time a government enacts a new tariff or counters with a reciprocal tariff, the cost of essential raw materials fluctuates sharply. As international trade relations become more complex—especially following actions by the trump administration —volatility has risen across all mineral-dependent industries. End buyers in the supply chain suffer, from automakers to electronics giants, forcing supply chain managers to constantly reassess their procurement strategies and pricing models.

Suppliers and buyers alike must also consider secondary consequences: hoarding, panic buying, and sharp swings in trade volume—all of which can amplify shortages and drive up prices further. With no sign of long-term stability, volatility driven by mineral tariff changes is now a risk that supply chain teams must budget for and manage on a quarterly, if not monthly, basis.

Reciprocal Tariff Policies: The New Norm for Global Mineral Supply Chains

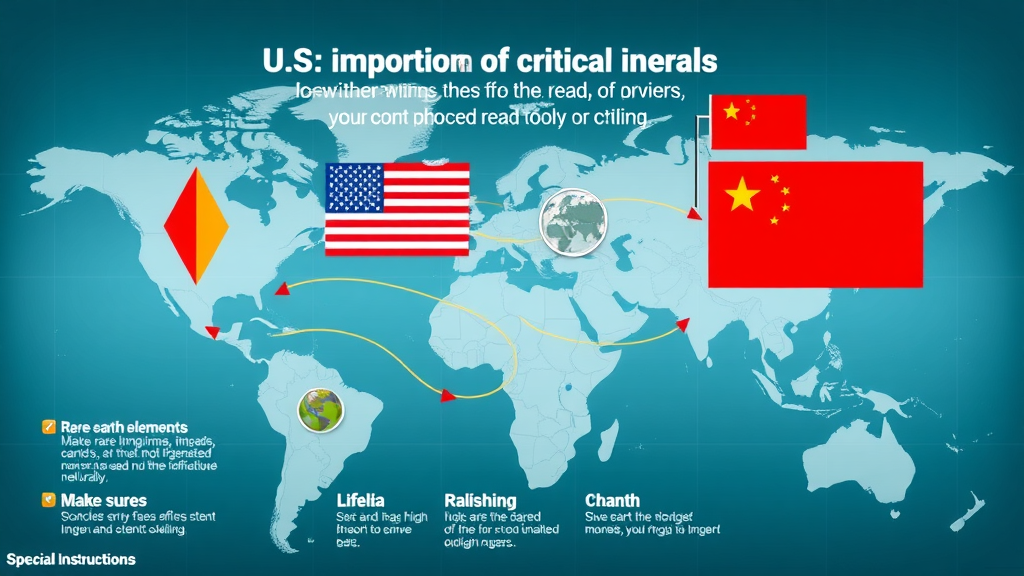

One of the most significant trends in mineral trade policy is the emergence of reciprocal tariffs as a standard operating procedure. When one nation implements a tariff hike on critical minerals , immediate reciprocal action is the norm, causing tit-for-tat escalations that trap companies between rising costs and regulatory uncertainty. These reciprocal tariff cycles are especially visible between the United States and China, where president trump and later administrations used tariffs as both negotiation tools and political statements.

The acceleration of these tactics has created a new reality for businesses reliant on critical mineral supply chains : constant vigilance and the necessity of strategic flexibility. Importers must not only monitor policy changes abroad, but also watch for retaliatory measures that may impact routes or add new compliance challenges.

"In the wake of sweeping mineral tariff changes, entire mineral supply chains are grappling with unpredictability. The stakes for national security and industrial growth have rarely been higher." – Industry Analyst

The Geopolitical Power Play: Mineral Tariff Changes, National Security, and Presidential Actions

President Trump and the Push for Stronger Critical Mineral Tariff Policies

The role of president trump marked a pivotal moment for U.S. mineral trade policy. By signing an executive order to bolster the domestic mining industry and reduce dependence on foreign minerals, the administration recalibrated the nation’s approach to mineral tariff changes . These actions included the imposition of new tariffs on imported rare earth elements and other strategic minerals widely used in defense, technology, and energy sectors.

The rationale was clear: protect domestic interests, improve economic security, and drive investments into local extraction and processing of critical minerals . Yet the ripple effects were global—prompting key trade partners to retaliate with their own tariffs and export controls, further destabilizing existing supply chains and pricing models.

Legacy of President Donald Trump: Impacts on Reciprocal Tariffs and Supply Chains

Under president donald Trump's leadership, the concept of reciprocal tariff policies became central to U.S. trade strategy. By prioritizing reciprocal treatment, the United States triggered waves of counter-tariffs from both allies and rivals, particularly for minerals crucial to national security and technology industries. One far-reaching effect was the uncertainty injected into global critical mineral supply chains , making it difficult for businesses to forecast costs or secure long-term contracts.

While some manufacturers applauded the efforts to level the playing field, others struggled with the resulting volatility. For many, the era of predictable tariffs was over, replaced by near-constant recalibration as reciprocal measures took hold from country to country.

How Mineral Tariffs Shape National Security Priorities

Mineral tariff changes are now widely considered matters of national security . Modern defense systems, renewable energy platforms, and high-tech manufacturing all depend on steady supplies of critical minerals . Tariff shifts initiated on security grounds—such as to counter foreign control of rare earth markets—have had sweeping effects. Policymakers increasingly view tariffs not merely as economic levers, but as key instruments for safeguarding intellectual property, ensuring strategic autonomy, and preventing potential disruptions by geopolitical rivals.

As recent decisions and executive orders demonstrate, the intersection of trade policy, mineral supply, and national security has become a battleground for global influence. Those who adapt to these realities can future-proof their operations; those who ignore them may face strategic setbacks that are hard to recover from.

"Tariff adjustments are no longer just trade policy—they are critical tools for advancing national security strategies in the mineral sector." – Policy Expert

How Mineral Tariff Changes Affect Your Trade: Practical Scenarios for Critical Mineral Supply

Case Study Table: Comparing Pre- and Post-Tariff Rate Impacts on Mineral Supply Chains

|

|

|

|

|

Impact of Tariff Rate Changes on Supply Chains by Region |

|

Region |

Previous Tariff Rate |

New Tariff Rate |

% Cost Increase |

Critical Mineral Impact |

|---|---|---|---|---|

|

United States |

5% |

25% |

15-20% |

Rare Earths, Lithium |

|

EU |

3% |

12% |

6-10% |

Cobalt, Nickel |

|

China |

2% |

15% |

10-14% |

Graphite, Rare Earths |

|

Asia-Pacific |

4% |

10% |

3-7% |

Copper, Manganese |

Industry List: Sectors Most Exposed to Volatility in the Critical Mineral Supply Chain

-

Automotive manufacturing

-

Electronics and chip makers

-

Renewable energy (solar, EVs, wind)

-

Defense and aerospace

-

Chemical processing

The effects of mineral tariff changes are not spread evenly across industries. Sectors such as automotive manufacturing , where electric vehicle components depend on a secure flow of critical minerals , are particularly exposed. Electronics and chip makers are often hit hard by every shift in global tariff rate policies, as even a minor disruption in the supply of semiconductors or specialty metals can translate to massive productivity losses. Renewable energy firms—especially those engaged with solar or wind technologies—are equally vulnerable, given their dependence on rare earths, lithium, and other strategic inputs.

The defense, aerospace, and chemical industries cannot ignore the threat either. As market volatility and reciprocal tariffs become the norm, the importance of action-ready risk management grows by the day.

Risk Management: Strategies to Anticipate and Respond to Mineral Tariff Changes

-

Diversify mineral supply chains

-

Increase inventory resilience

-

Build reciprocal trade partnerships

-

Monitor tariff rate announcements

To navigate the growing uncertainty, supply chain executives must take proactive steps:

Diversifying your mineral supply chains —sourcing from multiple countries—can reduce vulnerability to sudden tariff spikes. Maintaining higher levels of critical inventory adds resilience should a disruption occur, while forging reciprocal trade partnerships can buffer the effects of import tariffs.

Equally critical is the need to monitor tariff rate announcements from both domestic and international regulators; sometimes, just a few days’ notice can mean all the difference in securing affordable supply or facing price hikes.

Video Analysis: Navigating Mineral Tariff Changes in Real Time

Expert Panel: Critical Minerals and the Supply Chain After Recent Tariff Rate Changes

Industry experts agree: succeeding in this new era of critical mineral supply chains requires agility and constant learning. In recent discussions, panelists highlighted real-time adjustments to procurement contracts, increased reliance on data analytics to forecast market volatility , and the crucial role of interdepartmental communication—from compliance to logistics to finance. The consensus? Mineral tariff changes are a long-term reality, and those who build flexible teams and digital infrastructure will be best positioned to thrive, no matter the next announcement out of Washington, Beijing, or Brussels.

Video Deep Dive: How Reciprocal Tariffs Change the Landscape for Critical Mineral Supply Chains

Analyst Commentary: Adapting to Supply Chain Disruptions

Leading supply chain analysts stress that every participant—from supplier to manufacturer—needs adaptive playbooks for handling unexpected reciprocal tariffs . That means building in price buffers, hedging essential mineral purchases, and establishing rapid communication channels with global partners. Real-world examples show how companies able to “switch lanes” among suppliers or rapidly reroute logistics can minimize cost increases and ensure steady production despite tariff shocks.

Comparing Global Approaches: Mineral Tariff Changes and Reciprocal Tariffs Across Leading Economies

Major Trading Partners: Supply Chains Influenced by Mineral Tariff Fluctuations

|

|

|

|

Key Countries Implementing Recent Reciprocal Tariff Measures |

|

Country |

Tariff Policy |

Target Minerals |

Effect on Mineral Supply Chains |

|---|---|---|---|

|

United States |

25% additional tariff on critical minerals from China |

Rare Earths, Lithium |

Increased costs, sourcing diversification |

|

China |

Export controls and reciprocal tariffs on US-origin minerals |

Graphite, Cobalt |

Reduced US imports, new trade routes |

|

EU |

Tariff harmonization, retaliation for US steel/aluminum tariffs |

Nickel, Aluminum |

Trade diversion, cost volatility |

|

Australia |

Tariff-free agreements with Asia-Pacific partners |

Lithium, Manganese |

Stable export markets, increased global role |

Quotes from Industry Leaders on Critical Mineral Tariff Shifts

"We have never seen such rapid shifts in the mineral tariff environment. Every importer must stay nimble or risk losing market share." – Global Trade Executive

How Mineral Tariff Changes Cause Market Volatility in Mineral Supply Chains

Top Factors Amplifying Market Volatility for Critical Minerals

-

Unpredictable reciprocal tariffs

-

Sudden shifts in demand for battery metals

-

Disruptions due to national security concerns

-

Regulatory changes in key mineral supply countries

Market volatility is at an all-time high for global critical minerals . The biggest drivers are surprise government interventions, rapid rises in demand (such as for battery metals powering the electric vehicle revolution), and ongoing disruptions from security-driven export controls. Changes in regulations—especially in countries like the United States, China, and the EU—can instantly distort the global mineral supply chains , leaving importers and manufacturers scrambling for alternatives.

With so many moving pieces, even well-established supply chains must brace for unexpected shocks as the landscape evolves.

Action Steps: Stabilizing Your Supply Chain Amid Mineral Tariff Changes

The best defense is a strong, adaptable offense. Forward-thinking companies use data analytics to track upcoming tariff rate adjustments, maintain diversified supply chain networks across continents, and build relationships with backup suppliers. They also develop game plans for regulatory changes, including ready-to-activate alternative shipping routes and flexible manufacturing processes that can quickly adapt to shifts in raw material sourcing.

By investing in digital transformation and training staff to proactively monitor policy changes, businesses can turn volatility into an opportunity—positioning themselves as leaders, rather than laggards, in the future global minerals market.

Future Outlook: What Mineral Tariff Changes Could Mean for Critical Mineral Supply Chains

Emerging Trends in Global Tariff Rate Adjustments

Looking ahead, expect tariff rate adjustments to remain dynamic, as governments continually respond to shifting market and geopolitical realities. Growing demand for critical minerals —especially those tied to green tech and national security —means tariffs will increasingly be used as both economic and political tools. We will likely see more reciprocal tariffs, selective exemptions for essential industries, and an expansion of bilateral trade agreements designed to circumvent new barriers.

Companies who make future-proofing their critical mineral supply chains a top priority will be best placed to handle the twists and turns ahead.

Policy Recommendations for Ensuring Critical Mineral Supply Resilience

Policymakers and industry groups must collaborate to keep critical minerals flowing—especially for sectors essential to economic and national security. Recommendations include the creation of international early-warning systems for mineral tariff changes , ongoing investment in domestic extraction and processing, and incentives for supply chain diversification. Proactive diplomacy and engagement with global partners will also be crucial for reducing the pain of reciprocal tariff cycles.

"The next wave of mineral tariff changes will test the adaptability of every supply chain executive focused on critical minerals." – Economic Forecaster

Your Checklist: Evaluating Mineral Tariff Changes for Your Trade Operation

-

Is your supply chain diversified across trusted regions?

-

Are your procurement teams monitoring global tariff rate updates weekly?

-

Do you have alternative suppliers ready for key critical minerals?

-

Are you engaged with trade associations and policymakers?

-

Does your scenario planning include reciprocal tariff disruptions?

People Also Ask: Mineral Tariff Changes in Practice

Did Trump remove tariffs from China?

-

Despite calls for tariff relief, most tariffs on critical minerals and related sectors remained in effect under President Trump, with only limited exceptions and exemptions for certain supply chain necessities.

Will metal prices go up with tariffs?

-

Yes, mineral tariff changes frequently result in higher imported metal prices, raising costs throughout supply chains and impacting end-use manufacturers.

How will tariffs affect chip makers?

-

Chip makers dependent on critical minerals may face increased production costs and supply chain disruptions as a result of shifting mineral tariff policies and reciprocal tariffs.

What is the current tariff rate in the US?

-

US tariff rates on minerals vary widely but have increased materially for several critical minerals in recent years—averaging 10–25% depending on the mineral supply and trade partner.

Key Takeaways: Navigating the Impact of Ongoing Mineral Tariff Changes

-

• Mineral tariff changes are reshaping the global critical mineral supply chain

-

• Ongoing market volatility demands supply chain agility

-

• Businesses should diversify sourcing and monitor reciprocal tariff developments

-

FAQs on Mineral Tariff Changes

-

• What industries are most affected by mineral tariff changes?

-

• How do critical mineral tariffs relate to national security policy?

-

• What are effective risk mitigation strategies?

Looking Ahead: How to Prepare for Future Mineral Tariff Changes in Critical Mineral Supply Chains

-

With mineral tariff changes set to remain a central force in global trade for critical minerals, proactive adaptation is crucial. Refocus your supply chain strategies, monitor evolving tariff rate regimes, and stay engaged with policymakers and peers to maintain resilience.

Interested in the Evolving Mineral Tariff Landscape? Contribute Your Expertise

-

Have insights to share on global trade? Let's talk—call us at 203-271-7991 to explore contributing an article.

Act confidently: Build resilience into your supply chain and stay ahead of mineral tariff changes by diversifying sourcing, monitoring trends, and engaging with policy decision makers.

Recent developments in mineral tariffs are significantly impacting global supply chains and critical mineral markets. For instance, President Donald Trump’s announcement of a 50% tariff on copper imports has led to a surge in U.S. Comex copper futures, which jumped over 12% to a record high. This move is expected to stimulate domestic production but also introduces volatility in global copper pricing. ( reuters.com )

Additionally, China’s retaliatory measures, including restrictions on the export of critical metals such as tungsten, tellurium, bismuth, indium, and molybdenum, are further complicating the landscape. These export controls are a direct response to U.S. tariffs and are likely to affect industries reliant on these materials. ( mining.com )

Understanding these shifts is crucial for businesses to adapt their trade strategies effectively. For a comprehensive overview of the recent U.S. and Canadian metals and minerals tariff treatments, including specific tariff rates and exemptions, refer to the detailed analysis provided by McCarthy Tétrault. ( mccarthy.ca )

Staying informed about these developments is essential for navigating the evolving trade environment and mitigating potential risks associated with mineral tariff changes.

Add Row

Add Row  Add

Add

Add Row

Add Row  Add

Add

Write A Comment