Understanding Safety-Critical Components in Electrical Equipment

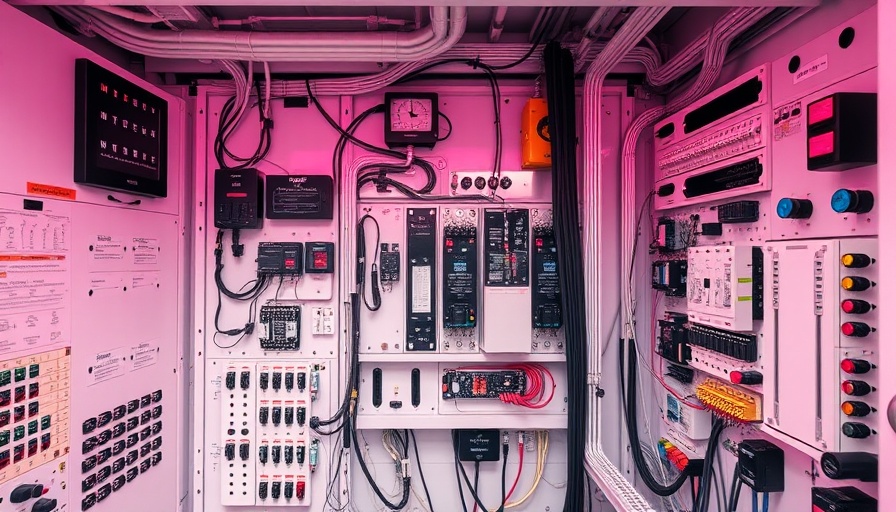

In the world of electrical equipment, ensuring safety is paramount. Safety-critical components are integral elements designed to prevent hazardous situations that could lead to injuries or damage. Their failure would not merely disrupt functionality but potentially create dangerous conditions during various stages, including production, transportation, and use.

Crucially, safety-critical components span a variety of parts such as power supplies, circuit breakers, and even software, which is becoming increasingly recognized as essential given its role in the safety infrastructure of devices. Each component must undergo rigorous third-party evaluations, such as those offered by Underwriters Laboratories (UL), to ensure they meet strict safety standards.

Key Types of Safety-Critical Components

Examples of safety-critical components abound, including:

- Power supplies

- Transformers

- Fuses

- Circuit breakers

- EMI filters

- Batteries

Every component plays a distinct role in mitigating risks present throughout the lifetime of an electrical product. Beyond hardware, software has also emerged as a critical factor in safety considerations, as it serves to manage data and operational protocols that affect a product's reliability.

The Importance of UL Standards and Certifications

UL has been at the forefront of establishing safety standards for over 125 years, with a portfolio of more than 500 standards dedicated to electrical safety. These standards help to assure manufacturers and consumers that electrical devices will function without significant risk of harm.

For example, UL standards include guidelines for construction, performance, and testing, ensuring products are safe when installed correctly. Markings of compliance, such as the UL Listing Mark, signify that a product has met crucial safety practices and can drastically reduce incidents of shock, fire, and other hazards.

How to Validate Safety-Critical Component Compliance

To harness the safety benefits of critical components, manufacturers must ensure components are UL approved. An approval certificate or the manufacturer's data sheet alone is not enough; products should visibly display the certification mark, confirming compliance. This is particularly vital as components may not always display certification directly due to space restrictions.

The Risks of Non-Compliance: A Cautionary Note

Failure to comply with UL standards can lead to catastrophic results. A striking statistic highlights the gravity of electrical hazards, revealing that electrical issues contribute to approximately 46,700 home fires annually. These statistics underline the necessity for businesses engaged in import and export to equip their products with recognized, compliant safety components.

Future Trends and Evolving Standards

As technology advances, so do the standards governing safety-critical components. For instance, the integration of recycled materials in electrical devices is gaining traction, with UL developing standards to ensure safety in these innovations. As an importer or exporter, staying informed on these trends and adhering to evolving standards will be crucial in maintaining compliance and ensuring product safety.

Take Action: Ensure Your Components Are Safe and Compliant

For companies engaged in the global electrical markets, understanding and implementing UL standards can not only mitigate risks but also instill consumer trust. Whether you’re involved in manufacturing, importing, or exporting electrical equipment, prioritizing compliance with safety-critical components is essential. Be sure to validate your components and stay ahead of industry risks as technology progresses.

Add Row

Add Row  Add

Add

Write A Comment