Why Fast, Precision Steel Plate Burning Matters More Than Ever

Walk onto any construction site, fabrication shop, or major industrial project, and you’ll quickly spot a universal challenge: how to cut thick, tough steel plates precisely, efficiently, and cost-effectively. Whether building bridges, manufacturing equipment, or assembling vital infrastructure, delays and inaccuracies in metal cutting can compromise safety, waste materials, or send entire schedules veering off track. This is where the process known as steel plate burning emerges as an unsung hero—solving challenges that once seemed unsolvable.

But what exactly makes steel plate burning such an indispensable force for modern metalworking? For decades, fabricators relied on manual torch cutting or basic machines that too often resulted in uneven edges and extra post-cutting work. Today’s clients, however, demand tight tolerances, greater speed, and minimal waste. With rising costs, stricter demand for quality, and the need for custom cuts on short timelines, it’s never been more critical to master the art and science of this essential method. Understanding steel plate burning isn’t just for technical insiders—it’s for anyone who values smart solutions to today’s toughest industrial challenges.

Cutting Through Complexity: What Sets Steel Plate Burning Apart in Metalworking

At its core, steel plate burning is the process of precision-cutting large steel sheets to specific sizes and shapes using high-energy tools—often using gas or plasma. Unlike traditional saws or manual tools, which can leave rough or uneven edges, advanced burning methods use a tightly controlled heat source to melt and separate metal along a predetermined path. When paired with computer-guided equipment, this approach can create intricate parts, sharp corners, and consistent finishes that require little or no edge grinding.

The adoption of CNC-enabled plasma and oxy-fuel burning isn’t just about producing cleaner cuts: it’s about transforming what’s possible with steel. By integrating additional processes such as plasma cutting and post-cut finishing, fabricators gain control over quality, timing, and material usage—core factors in any successful project. Neglecting advancements in steel plate burning can result in excessive material waste, inferior fit, and costly do-overs. That’s why knowing the ins and outs of plate burning is crucial not only for shop owners and engineers, but also for project managers and anyone responsible for getting top results in a demanding industry.

Precision, Versatility, and Value: Why Cutting-Edge Plate Burning Outpaces Outdated Methods

Industry experts, such as the specialists at Infra-Metals Co. (a major structural steel service provider recognized for their comprehensive approach), emphasize how next-level steel plate burning redefines project outcomes. Leveraging high-definition plasma machinery with tighter nozzles than traditional equipment, modern providers deliver high-tolerance cuts. The result is finished steel that demands minimal edge grinding—a clear advantage for speed, safety, and labor cost savings.

The benefits of integrating precision plate burning extend well beyond the physical properties of each cut. Faster turnaround times, improved part uniformity, and less post-fabrication work mean projects can move from the planning table to active construction or manufacturing with fewer bottlenecks. For clients and contractors alike, this translates to better material optimization, lower overhead, and the confidence of working with steel that meets or exceeds specification right from the start. In a competitive market, these advantages drive both profitability and peace of mind.

How High-Definition Plasma Burning Raises the Standard for Steel Fabrication

The transition from manual torch work to high-def plasma burning represents a seismic leap in the steel industry. Unlike standard plasma or oxy-fuel cutting, modern high-definition burners deploy a more concentrated plasma arc through a finer nozzle, focusing heat energy for maximum accuracy. This results in not only narrower kerf widths, but also smoother, more uniform edges—qualities that reduce the need for additional grinding or machining. Infra-Metals’ approach, for instance, puts this technology to work by prioritizing finished products that are ready for immediate use or further fabrication, minimizing the “gap” between raw steel and finished component.

By streamlining these processes, steel service centers can meet tight deadlines with confidence and adapt quickly to custom or large-scale requests. The versatility of plate burning expands possibilities—enabling the efficient creation of brackets, gussets, base plates, and custom designs that would challenge conventional saws or presses. Ultimately, adopting high-def plasma burning boosts reliability while empowering businesses to respond proactively to client needs, adding measurable value at every project stage.

Integrating Plate Burning with Value-Added Services: An End-to-End Solution

Steel plate burning doesn’t exist in a vacuum—it’s often part of a larger suite of fabrication services that together create a seamless supply chain. Providers like Infra-Metals demonstrate how clients can benefit from incorporating plate burning with additional value-added processes such as drilling, forming, blast & prime, cambering, and saw cutting . When these services are unified within one distribution model, customers avoid the logistical headaches and quality variation that often come from juggling multiple suppliers.

This end-to-end approach means that a project’s steel components can be cut, drilled, bent, finished, and prepped for installation, all with minimal handling and maximal precision. Especially for intricate builds or rapid deployment projects, this connected workflow improves project efficiency, traceability, and material integrity—key factors in both construction quality and regulatory compliance.

The Time-Saving Edge: Reducing Downtime and Wasted Material

Precision steel plate burning is an invaluable ally in reducing material waste and unplanned downtime—issues that routinely threaten even the most well-orchestrated builds. Because advanced machinery ensures consistent cuts and edge quality, less material ends up scrapped or reworked. In addition, streamlined programming and computer-guided nesting can optimize each plate to maximize yield, further minimizing waste and improving project economics.

Those who invest in state-of-the-art burning methods see results in the form of tighter turnaround windows and reduced dependency on secondary finishing. For project managers and procurement professionals, this delivers predictability and accountability, helping keep projects on schedule and within budget, no matter the complexity of the cut list.

Expert Philosophy: The Infra-Metals Approach to Modern Steel Plate Burning

At the heart of innovative steel plate burning is a philosophy built on integration, precision, and unyielding commitment to customer needs. Infra-Metals has established itself as one of the largest structural steel service providers in the United States by aligning distribution capabilities with regional needs and by maintaining a steadfast pursuit of high-quality, prompt, and economical service. Their emphasis on being a ‘one-stop shop’ reflects a deeper mission: to reduce friction in the supply chain and to bring technological excellence—like high-definition plasma cutting—directly to the fore of every project.

The company's investment in modern cutting and processing methods mirrors a belief in the value of continuous improvement. By combining cutting-edge technology with knowledgeable staff and custom distribution models, Infra-Metals helps ensure that every plate cut aligns with stringent industry standards and client demands. The goal isn’t just to provide steel—it’s to deliver comprehensive, reliable solutions that empower customers to build with confidence, efficiency, and accuracy.

This commitment extends across their portfolio, where quality and client satisfaction are not buzzwords but operational standards. Whether for custom fabrication, large infrastructure work, or heavy industrial needs, Infra-Metals’ focus on precision and customer partnership defines their reputation in a competitive landscape that values both speed and certainty.

What Success Looks Like: Real-World Validation from Those Who Rely on Plate Burning

When clients leverage advanced steel plate burning, the difference is apparent not just on paper, but in finished structures, delivered projects, and streamlined workflows. While formal review quotes are sparse in public listings, the broader industry consensus—and extensive demand for steel cut to precise standards—speaks volumes about the everyday successes realized through high-definition plate burning.

[No suitable customer review was provided from the Google listing, but industry-wide adoption and continual growth in steel plate burning services demonstrate ongoing trust and satisfaction in the method.]

For anyone invested in the success of industrial builds or custom fabrications, the smart utilization of steel plate burning is a proven path toward achieving results quickly, safely, and with absolute reliability. The right process, backed by expertise and technology, can transform what’s possible—and set new standards for project delivery and success.

Why Precision Steel Plate Burning Remains Essential for Competitive Projects

As the demand for tighter tolerances, faster timelines, and top-tier material utilization rises, the importance of advanced steel plate burning only continues to grow. Industry leaders like Infra-Metals bring depth and technology to this process, demonstrating that cutting-edge plate burning is more than a commodity—it’s a bridge to project certainty, cost efficiency, and unmatched build quality. When steel is cut right the first time, every stakeholder from fabricator to end user benefits.

From bridges to buildings and everything between, steel plate burning remains a cornerstone of progress in construction and manufacturing. Companies committed to advancing these technologies—guided by a service-first philosophy—stand at the leading edge of the industry, shaping the future one precisely cut plate at a time.

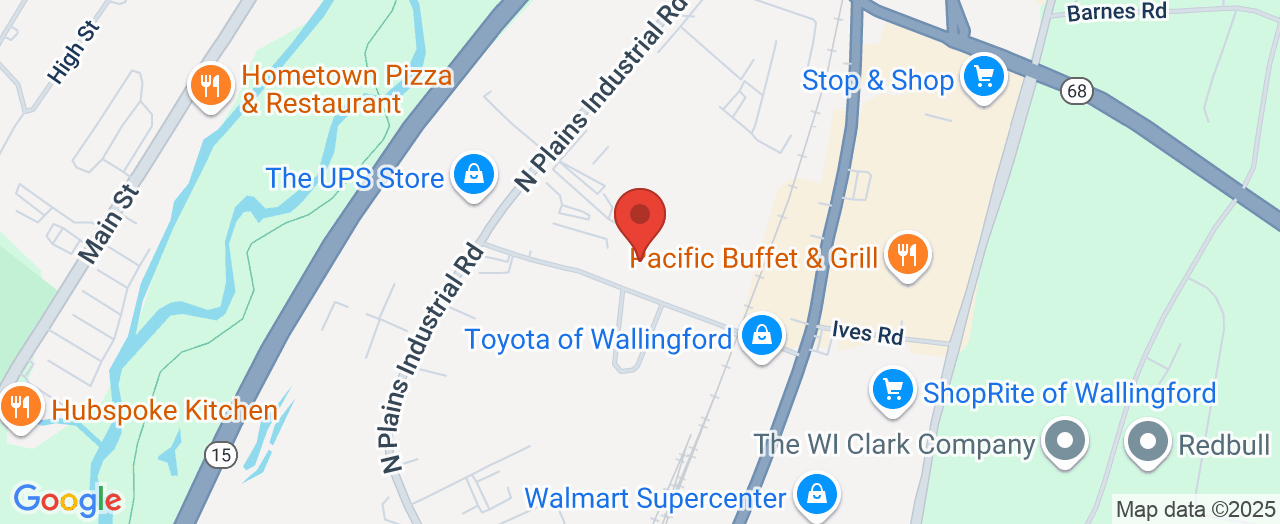

Contact the Experts at Infra-Metals Co. - New England Division

If you’d like to learn more about how steel plate burning could benefit your next structural steel project, contact the team at Infra-Metals Co. - New England Division. 📍 Address: 55 Pent Hwy, Wallingford, CT 06492 📞 Phone: +1 800-243-4410 🌐 Website: http://www.infra-metals.com/

Infra-Metals Co. - New England Division Location and Availability

🕒 Hours of Operation: 📅 Monday: 8:00 AM – 5:00 PM📅 Tuesday: 8:00 AM – 5:00 PM📅 Wednesday: 8:00 AM – 5:00 PM📅 Thursday: 8:00 AM – 5:00 PM📅 Friday: 8:00 AM – 5:00 PM📅 Saturday: ❌ Closed📅 Sunday: ❌ Closed

Add Row

Add Row  Add

Add

Add Row

Add Row  Add

Add

Write A Comment