Finding the Right Material: A Balancing Act

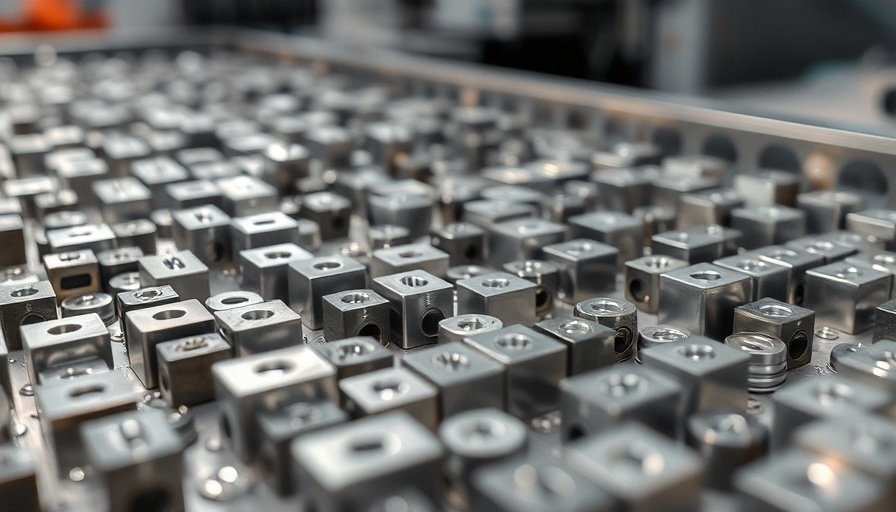

In the realm of precision metal stamping, choosing the right materials is not just a technical decision—it’s a strategic one. Importers and exporters need to consider both cost and availability, especially in industries like automotive, aerospace, and medical devices. While it might be tempting to choose materials based solely on performance metrics, overlooking cost implications can lead to inefficiencies that strain profitability.

Cost Analysis: The Price of Progress

When it comes to high-volume production, selecting the right material can significantly impact your bottom line. Common choices, like stainless steel and aluminum, are favored for their cost-effectiveness and adaptability. However, specialty components that require unique materials, such as titanium alloys, can incur higher costs. It's crucial to evaluate the total cost of ownership, considering not just the material costs but also processing and compatibility with existing equipment.

The Long Game: Material Availability

Material availability poses another layer of complexity in metal stamping. Supply chain disruptions can lead to delays, driving up costs and impacting delivery commitments. Importers and exporters must understand market dynamics, staying ahead of trends in material sourcing and production capabilities. Establishing partnerships with suppliers that have diverse inventory options can mitigate risks associated with shortages.

Global Supply Chains: The Big Picture

Geopolitical tensions and tariffs can complicate procurement strategies, making it vital to partner with suppliers who understand the intricacies of the global market. Keeping a close eye on these factors allows businesses to adapt their sourcing strategies proactively, thereby ensuring material availability and cost controls remain aligned with production goals.

Best Practices for Effective Material Selection

To optimize material choices, it's essential to leverage the expertise of metallurgists and engineers. Engaging with experts can reveal more economical options that do not compromise performance. Additionally, establishing strong relationships with suppliers can open doors to valuable insights, helping businesses forecast material needs and costs effectively.

Embracing Sustainability for Long-term Success

Another important consideration for importers and exporters is sustainability. Choosing recyclable materials or those with lower environmental impacts can align with corporate responsibility goals and mitigate future regulatory risks. As more industries focus on sustainable practices, adjusting sourcing strategies to reflect these values can improve a company's reputation and operational efficiency.

Conclusion: Partner for Success

Navigating the complexities of material selection in precision metal stamping demands a thorough analysis of costs, market conditions, and sourcing challenges. Collaboration with experienced suppliers, such as Ulbrich Stainless Steels & Special Metals, can provide crucial support in achieving an effective balance between cost and performance. To learn more about how Ulbrich can assist in your material needs, contact us today!

Add Row

Add Row  Add

Add

Add Row

Add Row  Add

Add

Write A Comment