Did you know that over 80% of industrial automation relies on servo motors, yet many manufacturers face costly downtime due to motor failures? Understanding the nuances of servo motor repair expert insights is critical to maintaining operational efficiency in today’s fast-paced manufacturing environment. This article delves into the intricate world of servo motor repair, revealing the expertise, challenges, and advancements shaping the industry through the perspective of Michael Norman, the seasoned professional behind ServoTech Incorporated.

What You'll Learn: Key Insights from a Servo Motor Repair Expert

The evolution and importance of servo motor repair services in modern manufacturing

Common motor failure causes and how expert repair services address them

Challenges faced by the servo motor repair industry, including workforce and supply chain issues

Technological advancements and capabilities that set leading repair services apart

Best practices and actionable tips for maintaining servo motors to prevent costly downtime

Overview of Servo Motor Repair Services and Industry Trends

Defining Servo Motor Repair and Its Role in Industrial Automation

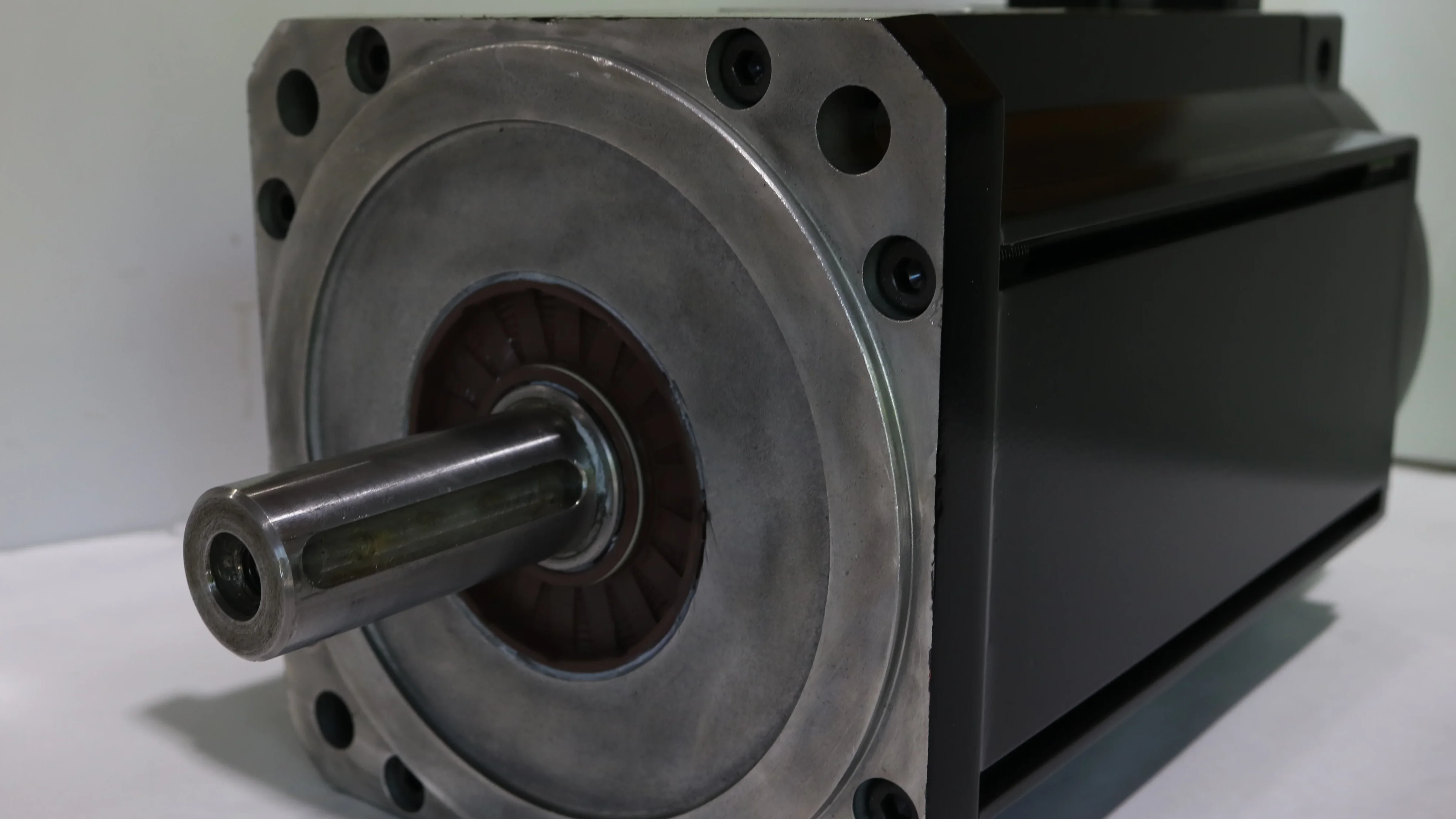

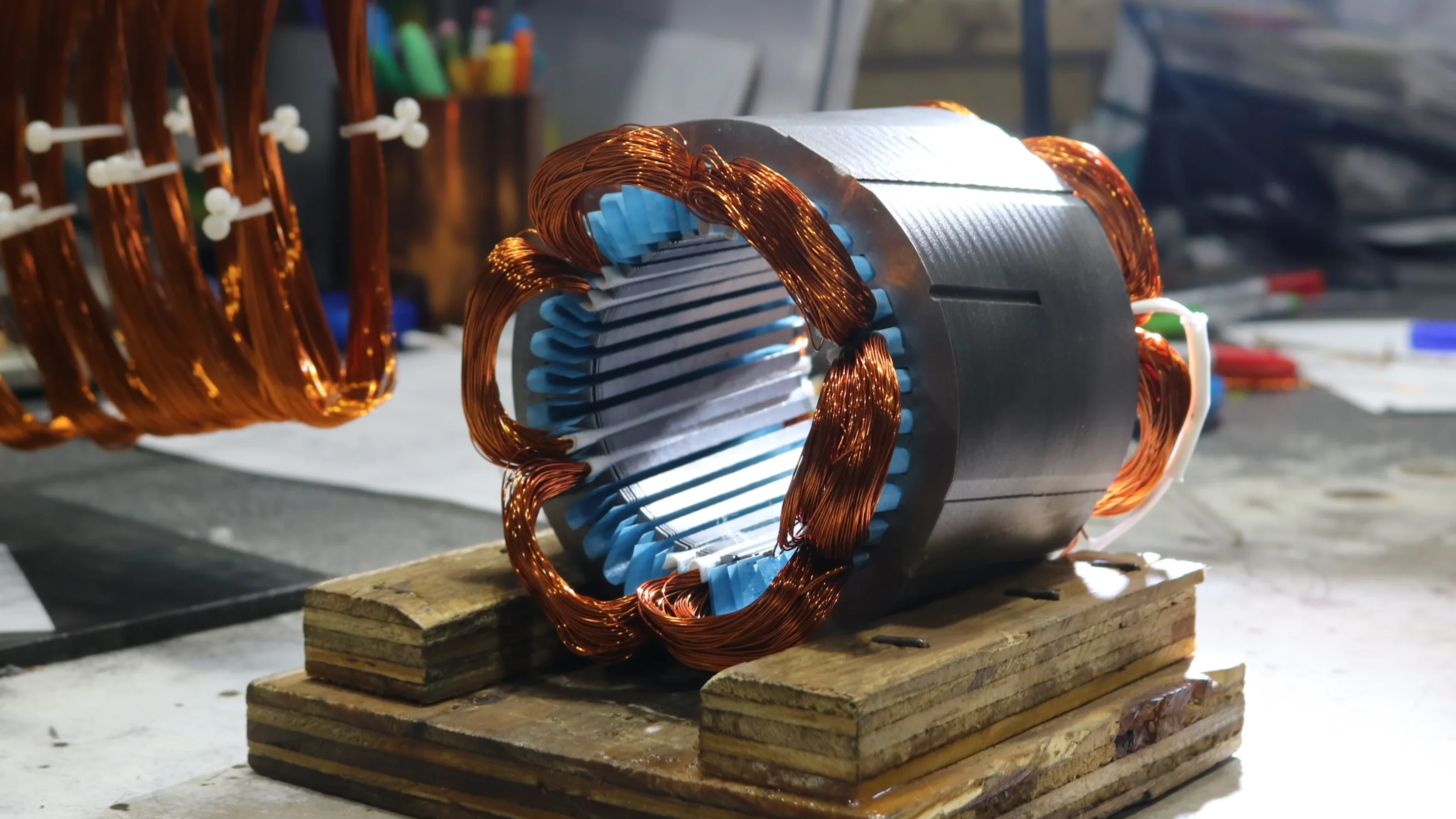

Servo motor repair involves comprehensive refurbishment of high-precision motors integral to automated manufacturing equipment. These motors operate as closed-loop systems, integrating sophisticated feedback devices to allow precise control over machine movements, such as indexing and rotary tables, CNC machines, and robotic arms. The repair process requires restoring critical components like stator windings, bearings, encoders, and electronic feedback systems to factory specifications to ensure optimal performance and extended equipment lifespan.

Michael Norman of ServoTech states that their approach goes beyond simple fixes: they "treat the unit as a whole, refurbishing your entire motor back to factory specifications rather than just fixing what's wrong." This comprehensive service mitigates recurring failures and helps prevent unscheduled machine downtime, which can be financially crippling for manufacturers relying on continuous production lines.

Current Trends in Servo Motor Repair Services

The servo motor repair industry is evolving alongside advancements in industrial automation. Today's machines employ increasingly sophisticated motors equipped with advanced encoders and electronic feedback systems, requiring specialized diagnostic and programming capabilities. Industry leaders invest heavily in proprietary software and diagnostic tools to troubleshoot, refurbish, and reprogram motors and encoders from a wide variety of manufacturers, including FANUC, Yaskawa, Panasonic, Mitsubishi, Siemens, and Allen-Bradley.

Michael points out, “We invest heavily in equipment and software, spending around $10,000 a month to stay current with over 100 manufacturers worldwide.” This ongoing investment allows ServoTech to provide precise repairs and encoder programming and calibration that many competitors cannot match.

Common Motor Failure Issues and Repair Solutions

Typical Causes of Motor Failure in Servo Motors

Servo motors can fail for many reasons, often related to harsh industrial environments and prolonged wear. Common issues include winding insulation degradation, bearing wear, encoder failures, electronic component damage, and overheating. Physical damage caused by improper handling or machine malfunctions also contributes to motor breakdowns. Early diagnosis is critical to prevent collateral damage to expensive machinery and costly production downtime.

Michael describes the complexity of these failures, stating that “encoder feedback devices can transmit up to 1.4 million pulses per revolution, so precision diagnosis and repair of these components is essential.” Understanding these failure modes allows repair experts to tailor accurate, long-lasting solutions rather than superficial fixes.

How Expert Motor Repair Services Diagnose and Fix Motor Issues

Common Motor Failure |

Repair Technique |

Result / Benefit |

|---|---|---|

Winding insulation failure |

Complete rewind of stator coils using precision tools |

Restores motor electrical integrity, lasting durability |

Bearing degradation |

Replacement with OEM-grade bearings and precision fitting |

Reduces noise, vibration, and premature wear |

Encoder malfunction |

Diagnostic testing and programming or replacement of encoders |

Ensures accurate feedback for closed-loop control |

Electronic component damage |

Comprehensive electronic board repair or replacement |

Restores motor control functions and communication |

Physical damage and wear |

OD grinding and mechanical refurbishment |

Extends mechanical life, improves fit and running smoothness |

Challenges Facing the Servo Motor Repair Industry Today

Workforce Shortages and Changing Work Ethic

The servo motor repair industry is confronting a significant workforce challenge. Finding skilled technicians with both mechanical and electronic expertise is increasingly difficult. Michael Norman shares, “Help is hard to find; I have to hire 10 to 15 people to get one good employee. Today's workforce mindset is very different from what we had.”

This shortage impacts turnaround times and the ability to scale operations. Veteran technicians with deep knowledge are rare, and companies struggle to attract younger workers who often prioritize work-life balance differently, complicating operational sustainability.

Supply Chain Disruptions and Tariff Impacts on Repair Services

Supply chain disruptions and tariffs have added new complexities to repair services. Many critical components such as encoders and electronic parts are imported from countries like Japan, Germany, and Taiwan. These imports are subject to tariffs that increase costs, which are often passed on to customers.

Michael explains, “I am for the tariffs because the long-term gains for the United States will help us. Short term, it’s Fcrippling the industry.” He notes that tariffs add about 10% to costs but believes encouraging domestic manufacturing is vital for America's industrial future.

Technological Capabilities and Competitive Advantages in Servo Motor Repair

Advanced Diagnostic Tools and Software for Servo Motor Repairs

Today's servo motor repair services rely on cutting-edge diagnostic tools that test motors dynamically on factory drives, analyze vibration and balance, and calibrate complex encoders. Michael emphasizes the importance of owning a broad spectrum of software and test equipment to service over 100 manufacturers globally.

This advanced testing ensures every motor is returned in "like-new condition," minimizing repeat failures and maximizing customer trust and uptime.

How ServoTech USA Stands Out Among Competitors

Unlike companies that stockpile inventory, ServoTech focuses on technical mastery and comprehensive refurbishment. Michael explains, “We don’t keep a million dollars worth of stock because that’s not in our wheelhouse. Instead, we provide capabilities that others lack and do better work.”

This client-first philosophy means ServoTech will work with customers to find exactly what they need and find a solution that works for everyone, ensuring reliability and satisfaction.

Best Practices and Preventive Maintenance for Servo Motors

Routine Maintenance Checklist to Avoid Motor Failures

Preventive maintenance is crucial to reducing downtime and extending motor lifespan. A systematic approach includes regular inspection of critical components and feedback devices, timely replacement of worn parts, and using OEM components during repairs.

After repair, dynamic testing on factory drives verifies motor performance before returning units to service, securing smooth operation in automation systems.

Tips from Industry Experts on Extending Servo Motor Lifespan

Regular inspection of encoders and feedback devices

Timely replacement of worn components

Use of OEM parts for repairs and replacements

Dynamic testing on factory drives post-repair

Maintaining detailed service records

People Also Ask (PAA): Common Questions About Servo Motor Repair

What are the signs that a servo motor needs repair? Unusual noises, overheating, inconsistent motor performance, and error codes from the machine’s control system often signal required repairs.

How long does a typical servo motor repair take? Most standard repairs are completed within 5 to 10 business days, after an evaluation period of up to around 3 days. Along with a rapid response option that will have the motor refurbished in 48 hours as long as parts are in stock, after receiving the PO or acknowledgement from the customer.

Can all servo motors be refurbished to factory specifications? Expert services refurbish motors to meet or exceed factory specs, ensuring long-term reliability.

What is the warranty on repaired servo motors? Leading repair firms like ServoTech offer up to a one-year warranty from the date of installation.

How do tariffs affect the cost of servo motor repair services? Tariffs on imported parts add around 10-15% to parts costs, reflected in service pricing but support domestic industry revival.

Key Takeaways from a Servo Motor Repair Industry Veteran

Servo motor repair requires comprehensive refurbishment, not just quick fixes.

Workforce challenges and supply chain issues are significant hurdles in the industry.

Investing in advanced diagnostic tools is essential to maintain competitive repair services.

Preventive maintenance is critical to reduce costly downtime and extend motor life.

Tariffs, while increasing short-term costs, may encourage domestic manufacturing growth.

Conclusion: Embracing Expertise and Innovation in Servo Motor Repair

Mike of ServoTech USA concludes, "This client-first philosophy means Servotech will work with customers to find exactly what they need and find a solution that works for everyone, ensuring reliability and satisfaction." Prioritizing deep expertise, technological investment, and honest customer commitment is key to thriving in the servo motor repair industry.

Call to Action

Contact ServoTech USA to learn more about expert servo motor repair services.

Schedule a consultation to discuss your motor repair needs and minimize downtime.

Subscribe to our blog for ongoing insights and updates in industrial motor repair.

Sources:

Add Row

Add Row  Add

Add

Write A Comment