Did you know 80% of laser welding process failures are caused by simple, preventable setup errors? These mistakes aren't just frustrating—they can cost thousands of dollars in rework, material waste, and delayed delivery. In today's high-precision manufacturing landscape, understanding every step of the laser welding process is crucial for quality, profitability, and staying ahead in your industry. This guide cuts through the confusion, saves you from expensive blunders, and ensures your beam welds are strong, precise, and reliable from the start.

Unveiling the Truth: Startling Facts About the Laser Welding Process

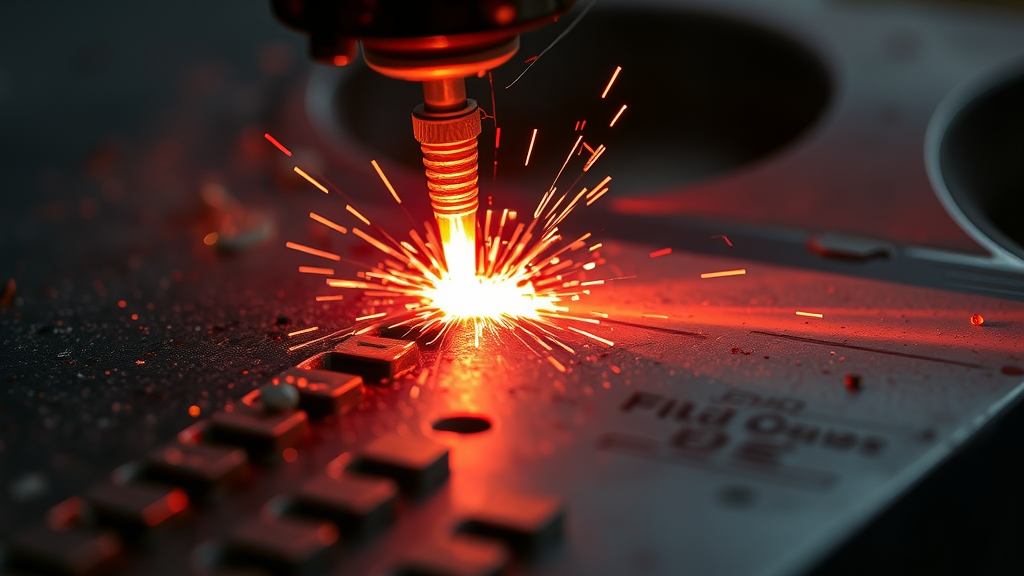

The laser welding process might seem futuristic, but it's a staple in countless industries requiring robust, high-weld integrity joins—from automotive chassis to medical implants. Unlike conventional arc welding, where large amounts of filler material and wide affected zones can compromise precision, the laser weld focuses intense energy precisely where it’s needed, often using a highly concentrated heat source—a laser beam.

What’s startling is just how much a small calibration mistake can wreak havoc. For example, setting an incorrect beam focus can lead to incomplete fusion or excessive porosity—defects hidden until costly inspections or failed product tests reveal them. Laser welding offers the promise of deep penetration , repeatable quality and minimal distortion, but only under tightly controlled process conditions. The differences between beam welding and traditional arc weld methods can significantly impact overall production costs and outcomes.

What You’ll Learn on Laser Welding Process Steps

- The core stages and critical controls in the laser welding process

- How laser beam welding ensures deep penetration and weld strength

- Common mistakes during laser beam weld operations—and how to avoid them

- Comparison to arc welding and conventional welding methods

- Industry applications and the advantages of laser weld over traditional processes

Breaking Down the Laser Welding Process: Step-by-Step Guidance

Mastering the laser welding process means more than just understanding how to operate the machine. Each step, from material selection to equipment setup, directly affects the quality, cost, and speed of your beam welds. Let’s break down this complex process into clear, actionable steps. By following proven procedures, you minimize the risk of flaws, maximize productivity, and unlock the full potential of laser beam welding—even for high welding speed applications. Whether you're new to beam welding methods or looking to avoid that one costly mistake, this walk-through equips you with practical, real-world techniques you can apply immediately.

Preparation and Material Selection for Laser Weld Success

Before turning on your laser welding system, it's essential to choose compatible materials. Not every metal responds to a laser beam in the same way; some, like stainless steel and certain aluminum alloys, are ideal due to their reflective properties and melting points. Understanding the limitations and recommendations for each material ensures your beam weld is both strong and durable. Pre-weld surface cleaning is another non-negotiable step. Any contamination—be it oil, dust, or oxidation—can disrupt the laser beam’s interaction with the surface, causing pores or incomplete fusion in the joint. Use isopropyl alcohol or specialized industrial cleaners for best results.

Finally, selecting the right joint configuration matters. Butt joints, lap joints, and T-joints each interact differently with the concentrated heat source and material thickness. The right setup maximizes penetration, minimizes affected zones, and delivers a high-quality, high-weld speed, repeatable result. Focusing on these early choices can mean the difference between routine production and expensive beam weld rework down the line.

- Understanding compatible materials for laser welding

- Pre-weld surface cleaning and its importance

- Selecting the right joint configuration for laser weld applications

Setting Up Equipment: Laser Beam Parameters and Machine Calibration

The next critical step in the laser welding process is equipment setup. Proper configuration of laser beam characteristics —power, focus, and spot size—directly determines penetration, weld quality, and speed. For instance, higher power density is typically required for thick-section welding to achieve full-depth fusion, while finer spot sizes maximize precision on delicate or thin materials. Adjust these settings based on your specific application, and consult your welding system’s guidelines for initial guidance before dialing in for optimal results.

Machine calibration and alignment also play a major role in avoiding errors. Misaligned optics, incorrect beam orientation, or improper workpiece positioning can turn a clean laser beam weld into a costly mess. Careful calibration—often checked with test coupons or automated vision systems—ensures the energy goes where it’s supposed to, minimizing wasted heat and saving both time and money across a wide range of beam welding applications.

- Configuring laser beam characteristics (power, focus, and spot size)

- Machine alignment and setup for optimal laser beam welding

Laser Beam Welding: Key Controls and Quality Parameters

Once your setup is complete, maintaining tight control over your laser beam weld is essential. Precision in every parameter—pulse settings, power, travel speed—produces high-integrity joints with deep penetration and minimal distortion. To achieve the best weld, every element of the process must work in harmony, from energy input to beam motion. Ongoing, real-time monitoring allows you to immediately adjust any deviations, preventing minor missteps from turning into major, costly failures.

The beauty of laser beam welding lies in its adaptability: you can switch between pulsed and continuous modes, fine-tune penetration, and create uniform weld beads even on complicated geometries. This flexibility makes it ideal for sectors that demand consistent results and tight tolerances.

Controlling the Laser Beam for Precision Welds

The secret sauce of a flawless beam weld is control. You’ll need to decide between pulse mode—where short, concentrated laser beams deliver precise, high-weld energy in bursts—and continuous wave modes, which provide a steady stream of heat for longer seams. Both have their place: pulsed laser welding excels in microelectronics or thin materials, while continuous mode is preferred for deep penetration and higher welding speed on robust assembly lines.

Monitoring penetration depth and weld bead formation during the laser welding process is crucial. Too little energy and the weld won’t penetrate deep enough, potentially causing incomplete fusion—a costly mistake if detected late. Excess energy, on the other hand, can cause excess spatter, a wide affected zone, or even part distortion. Using cameras, sensors, or even post-weld metallographic checks helps confirm each beam weld meets your precision standards, letting you adjust on the fly before errors escalate.

- Pulse settings and continuous wave modes

- Monitoring penetration depth and weld bead formation

Achieving Deep Penetration and Consistent Fusion

Deep penetration isn’t just a buzzword—it’s a key advantage of laser beam welding. Managing energy input ensures the laser beam reaches the full desired thickness, creating a solid, pore-free bond from top to bottom. Too little energy leaves a shallow bond, while too much can warp the metal or cause excessive heat-affected zones. The right balance delivers uniform fusion, exceptional mechanical strength, and a clean weld appearance.

Controlling travel speed and the path the laser beam takes across the workpiece is equally important. High welding speed is possible due to the concentrated heat source, but only if you calibrate movement so the laser and materials stay in sync. Automated systems can maintain consistent speed, ensuring every section of the laser beam weld is as strong as the last, even in mass production environments.

- Managing energy input for deep penetration benefits

- Controlling speed and travel of the laser beam

Avoiding Common Mistakes in the Laser Welding Process

Even with the best equipment and materials, common pitfalls can sabotage your results. Complacency in setup, contaminated workpieces, or poorly configured parameters can all cause failures—sometimes undetectable until costly repairs or recalls are needed. By understanding and preventing these issues in your laser welding process, you can consistently deliver high weld quality and minimize downtime.

Typical Laser Weld Flaws: Causes and Solutions

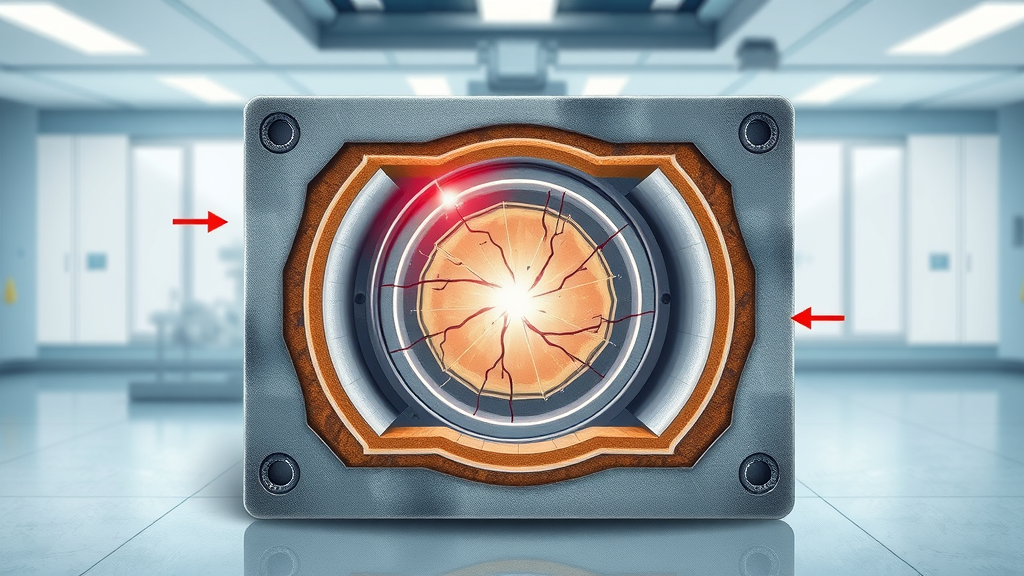

Flaws like cracking, porosity , and incomplete fusion are all too common in poorly executed laser welding systems. Cracking often results from excessive cooling or incompatible material choices, while porosity is typically caused by surface contamination or poor shielding gas coverage. Incomplete fusion may trace back to low energy input, an improperly focused laser beam, or uneven beam travel speed. To fix these, scrutinize your joint design, ramp up cleaning protocols, and verify laser settings before production runs.

For keyhole weld and keyhole welding errors, improper beam alignment or excessive energy can cause the molten pool to vaporize too rapidly, leading to voids or blowholes. Monitoring the stability of the keyhole and adjusting energy on the fly is key to remediation. By addressing these causes proactively, a skilled operator ensures each laser beam weld is consistent, eliminating repeat defects and expensive post-weld processing.

- Cracking, porosity, and incomplete fusion in laser beam welds

- Remediation strategies for keyhole weld and keyhole welding errors

Safety Considerations in Beam Welding Environments

The laser welding process comes with unique hazards—intense beams that can easily harm skin and eyes, reflectivity issues causing stray beams, and toxic fumes emitted from certain metals. Never, under any circumstances, shortcut your safety protocols. Always wear appropriate eye protection specifically rated for laser work, and ensure all beam paths are adequately shielded to contain reflections and prevent accidental exposure.

Think about your facility’s ventilation, too. Some welding processes generate fumes that require localized extraction or entire-room air handling solutions. Protective equipment such as gloves, fire-resistant attire, and beam-interlock safety setups should be in place on every beam welding job. Training staff on emergency shutdown procedures further ensures that even in the rare event of malfunction, you’re never caught unprepared.

- Hazards associated with intense laser beam exposure

- Protective equipment and setups for laser welding safety

"Laser welding stands out for its deep penetration and high-precision results, but even the smallest mistake in setup can lead to costly rework or catastrophic failure." — Industry Expert from Electronic Service Products

Laser Welding vs. Conventional Methods: Where Laser Weld Excels

Why choose the laser welding process over tried-and-true arc welding? The answer boils down to control, precision, and versatility. Compared to conventional arc weld methods, laser beam welding produces a much narrower affected zone, meaning less material warping and more precise, cleaner joint formation. The feedback control inherent in modern laser welding systems allows for automated monitoring, reducing operator fatigue, and raising weld quality standards across mass production lines.

The concentrated heat source delivered by a focused laser beam creates deeper penetration at higher speeds than most arc welding methods. This makes laser weld ideal for applications requiring minimal distortion and exceptional repeatability. Modern industries demand welds that are robust and cosmetically flawless—criteria where laser beam welding outperforms legacy methods like MIG and TIG. Furthermore, the process can join a wide range of metals, including those that are typically difficult to weld with conventional equipment.

Comparing Laser Beam Welding, Arc Weld, and Arc Welding

When it comes to energy control , the laser welding process has a distinct advantage. The fine-tuned focus of a laser beam means heat is applied only where needed, leading to lower overall heat input and less thermal stress on the workpiece. With arc welding, energy spreads over a larger area, often creating wider affected zones and requiring post-weld clean-up or reshaping. Beam welding methods—such as laser beam weld—excel in adaptability, easily handling everything from microelectronic joints to thick aerospace alloys.

Speed is another benefit: laser welding achieves high welding speed without sacrificing quality. Its flexibility also means fast changeover between jobs—a crucial factor for modern, high-mix manufacturing environments. For many operations, the reduced need for filler material and post-processing make laser weld an all-in-one, cost-effective welding process.

- Energy control in laser beam systems vs. arc welding

- Speed, flexibility, and application range of beam welding

| Process | Penetration Depth | Heat Input | Material Range |

|---|---|---|---|

| Laser Welding Process | Deep | Low/Precise | Metals, Alloys |

| Arc Welding | Moderate | Higher | Metals |

| MIG/TIG Welding | Shallow-Moderate | Moderate | Metals |

Industry Applications: The Wide Range of Laser Welding Process Uses

Laser welding systems aren’t just lab curiosities—they’re vital tools in industries that demand speed, accuracy, and performance beyond the reach of legacy welding methods. From automotive production to medical and aerospace manufacturing, the laser welding process enables more sophisticated designs, lighter components, and defect-free joints that meet or exceed global standards.

This wide range of applications is possible thanks to the process's versatility, deep fusion capability, and minimal need for filler material. As design tolerances tighten and new materials emerge, industries increasingly rely on beam welding’s unique strengths for competitive advantage.

Automotive: Spot and Seam Laser Welding for Lightweight Components

In the automotive sector, reducing vehicle weight is key for efficiency and environmental goals. Here, spot and seam laser welding processes shine. Robotic arms can lay down thousands of consistent spot welds in minutes, joining high-strength steels and exotic alloys in chassis and engine components. The deep penetration and minimal distortion of laser beam weld means thinner materials can be joined securely, supporting both crash safety and lightweighting initiatives. Automated beam welding lines also cut cycle times and virtually eliminate the need for extensive post-weld straightening or finishing.

Medical Devices and Electronics: Precision Laser Beam Welds

For medical and electronic manufacturing, cleanliness, repeatability, and microscopic accuracy are non-negotiable. The laser welding process enables assembly of tiny, delicate components—like pacemakers, micro-valves, and circuit enclosures—without the risk of excess heat damaging sensitive parts. Laser beam welding produces smooth, contamination-free joints that support device reliability and regulatory compliance. Minimally invasive heat-affected zones safeguard materials, preserve biocompatibility, and ensure the performance of every high weld in the batch.

Electronics benefit from similar advantages. The precise focus of the laser beam means components as thin as a hair can be joined accurately, supporting next-gen miniaturized designs for wearables, sensors, and mobile devices.

Aerospace and Beyond: Key Benefits of Laser Beam Welding

- Deep penetration

- Minimal distortion

- Clean, repeatable joints

Aerospace relies on beam weld techniques for joining critical engine parts, turbine blades, and airframe structures. Here, the advantageous combination of deep penetration and high welding speed supports both cost efficiency and stringent safety standards. Laser welding also minimizes the risk of microcracks and material fatigue, crucial for missions where failure is simply not an option.

Across all these industries, the laser welding process proves itself as more than just a joining method—it's a pathway to innovation, reliability, and market leadership.

Optimizing Your Laser Welding Process for Peak Efficiency

Unlocking the full potential of your laser welding process requires ongoing optimization—pushing for faster cycle times, consistent quality, and actionable real-time data. As you introduce new products or ramp up production, continuous improvement in equipment, processes, and operator skill will keep defect rates low and yields high.

Key opportunities include automating quality checks, integrating sensor feedback, and troubleshooting issues before they snowball into wasted material or schedule overruns. When each laser beam weld is exactly right, you boost both your team’s confidence and your bottom line.

Automation and Monitoring in Laser Beam Welding

Modern laser welding systems often include automated quality controls. These range from camera systems that inspect weld bead formation in real-time, to sensors that detect deviations in power or travel speed before poor joints are formed. The result: fewer defects, immediate operator feedback, and the ability to document weld quality for regulatory compliance or customer audits. Such controls support high weld-speed operations and are especially valuable for high-volume, safety-critical sectors such as automotive and aerospace.

Sensor-based monitoring forms the backbone of consistency in beam welding. By integrating data feedback loops into your workflow, minor process drifts are caught early—before they turn into major, costly process deviations. Data trends from these systems can also inform proactive maintenance or process improvement efforts.

- Real-time quality controls in laser welding

- Sensor-based monitoring for beam weld consistency

Troubleshooting: Quick Fixes for Common Laser Weld Problems

Even advanced laser welding processes face occasional hiccups. Common issues include misconvergence of the laser beam focus, causing irregular penetration or bead shape. If you spot a sudden drop in weld quality, check focus optics and recalibrate as needed—a simple correction can restore consistent performance. Alignment of joint setup is another frequent culprit; misaligned parts can lead to incomplete fusion or excessive top bead reinforcement. Use precision fixtures and in-process vision checks to confirm every joint is positioned perfectly before firing up your beam welding equipment.

Remember, ongoing training for your team ensures they spot these issues early, maintaining high weld quality and minimizing downtime.

- Laser beam focus adjustment

- Correcting joint alignment in laser beam weld setups

Expert Tips for Ensuring Laser Welding Process Reliability

- Routine equipment maintenance for beam welding systems

- Best practices for operator training and certification

To achieve flawless beam weld results every time, institute regular maintenance on your laser welding systems—this includes lens cleaning, calibration, and beam alignment verification. Preventive care catches optics degradation and positional errors before they affect production runs. Equally important is investing in thorough operator training. Certification ensures staff understand equipment nuances, process variables, and key safety protocols for every type of laser welding process. When everyone on the floor knows what a perfect weld looks like and how to achieve it, mistakes sharply decline and productivity soars.

"With increasingly tight tolerances, laser beam welding remains unparalleled in delivering repeatable, contamination-free results across a wide range of industries." — Senior Process Engineer

People Also Ask:

Is laser welding stronger than TIG?

Laser welding can produce welds that are as strong or stronger than TIG, particularly for deep penetration applications and high weld integrity. The focused laser beam enables very narrow, high-strength joints with minimal affected zones. However, the ideal process depends on material type, joint configuration, and industry requirements; in some cases TIG may offer superior performance for filling gaps or working with specialty alloys.

Laser Welding Process Vs. TIG: Performance and Strength

When comparing laser welding to TIG, the laser beam welding method offers a higher energy density, allowing for faster welding speed, deeper penetration, and smaller heat-affected zones. TIG, favors more control in manual applications but is slower and creates a wider affected zone. For mass production or automated environments, laser weld consistently delivers superior strength and lower distortion in compatible materials.

What is the disadvantage of laser welding?

The main disadvantage of the laser welding process is its higher upfront cost—both for equipment and operator training. Sensitive calibration and maintenance requirements can challenge new users, and reflective materials like copper can be difficult to weld. Certain jobs requiring extensive filler material or unusual joint shapes may still be better suited to arc welding processes.

Understanding the Downsides of the Laser Welding Process

Laser welding systems require precise alignment and a clean working environment, increasing the demand for skilled operators. The high initial investment and the cost of ongoing maintenance can be a barrier for small operations. Additionally, thick or extremely reflective metals may challenge even the best laser beam weld setups, limiting universal applicability.

Is laser welding TIG or MIG?

Laser welding is a distinct process from both TIG and MIG. While TIG and MIG are types of arc welding—using a consumable (MIG) or non-consumable (TIG) electrode as the heat source—laser welding uses a focused laser beam as its heat source. Laser beam welding typically requires less filler material and achieves cleaner, stronger, and narrower welds compared to both TIG and MIG welding methods.

How Laser Welding Process Differs from TIG and MIG Welding

The laser welding process is unique in that it leverages a highly concentrated heat source, enabling rapid, deep penetration and minimal distortion. TIG and MIG are more versatile for filling wide gaps or for materials with high impurity, but cannot match the speed or precision of a focused laser beam weld, especially in automated setups or mass production.

Is laser welding possible?

Yes, laser welding is widely possible and used across a broad spectrum of industries such as automotive, aerospace, electronics, and medical device manufacturing. The process can be finely tuned to handle different materials and thicknesses, offering high weld quality when set up and monitored correctly.

Application Feasibility: Can All Metals Use the Laser Welding Process?

Most metals, including stainless steel, aluminum alloys, and titanium, are suitable for the laser welding process. Metals with high reflectivity or thermal conductivity, such as pure copper or thick aluminum, may require specialized settings or more powerful laser beams. The process continually evolves, allowing an expanding wide range of materials to be joined with beam weld technology.

Frequently Asked Questions on Laser Welding Process

- What types of lasers are used in welding?

- How does deep penetration affect laser welding quality?

- Can aluminum alloys be joined using the laser welding process?

Takeaways for an Efficient and Error-Free Laser Welding Process

- Meticulous setup and parameter control are crucial for laser beam weld quality

- Deep penetration and precision define laser welding’s biggest strengths

- Avoiding common process mistakes saves time and production costs

Enhance Your Manufacturing: Precision Laser Welding Process Solutions

- Facing Tariff Pressures? It’s Time to Reshore Smarter. At Electronic Service Products, we specialize in precision laser machining solutions that meet the highest quality standards—onshore, on time, and on budget.

- Whether you're looking to reshore your manufacturing or avoid the mounting cost of overseas tariffs, we offer the speed, precision, and flexibility your supply chain demands.

- 👉 Call today 203-265-4167 or go to espcnc.com/request-a-quote

Start optimizing your laser welding process: focus on meticulous setup, avoid common errors, and empower your team for flawless results with every beam weld!

To deepen your understanding of the laser welding process and its critical steps, consider exploring the following authoritative resources:

-

“Laser Welding” : This comprehensive guide from IPG Photonics details the laser welding process, including its advantages such as high precision, repeatability, and minimal maintenance requirements. ( ipgphotonics.com )

-

“What Is Laser Welding and How Does It Work?” : TWI provides an in-depth explanation of laser welding, covering its operation modes—conduction limited welding and keyhole welding—and the factors influencing weld quality. ( twi-global.com )

These resources offer valuable insights into optimizing your laser welding procedures and avoiding costly mistakes.

Add Row

Add Row  Add

Add

Write A Comment