Did you know? Over 60% of manufacturers reported significant electronics supply chain disruptions in the last three years, leading to a dramatic rethinking of sourcing and production strategies. As the world becomes more connected yet vulnerable to unexpected shocks, companies are swiftly moving from traditional offshore models and mastering electronics supply chain reshoring to secure their future growth. Read on to discover why reshoring is not just a passing trend, but a critical strategy to stay ahead.

Startling Realities: The State of Electronics Supply Chain Reshoring

"Over 60% of manufacturers reported significant electronics supply chain disruptions in the last three years, prompting a drastic shift toward reshoring strategies."

Key statistics reveal global electronics supply chains remain vulnerable despite advances in digital tracking and forecasting technologies.

Frequent supply chain disruptions—spanning component shortages to clogged shipping lanes—are the main drivers forcing electronics manufacturers to consider reshoring to regain control.

The initial impacts on electronics manufacturing competitiveness include increased production costs, longer lead times, and fierce pressure to innovate in both process and product.

What You'll Learn About Electronics Supply Chain Reshoring

Clear definition and vital role of electronics supply chain reshoring

Critical benefits and challenges facing the electronics manufacturing sector

Strategic, step-by-step guide to master reshoring in electronics manufacturing

Essential risk mitigation methods and how to improve quality control

Understanding Electronics Supply Chain Reshoring

Defining Electronics Supply Chain Reshoring in Modern Manufacturing

Electronics supply chain reshoring is the process of returning the manufacturing of electronic components, devices, and finished goods—or key parts of that process—back to domestic facilities, often after having sourced them from overseas for years. This strategic move reverses decades of offshoring in electronics manufacturing, responding to increased supply chain risk, difficult lead times, shifting labor costs, and rising tariffs. While offshoring once offered attractive cost savings, modern manufacturing demands more localized, agile supply chains—especially for critical components.

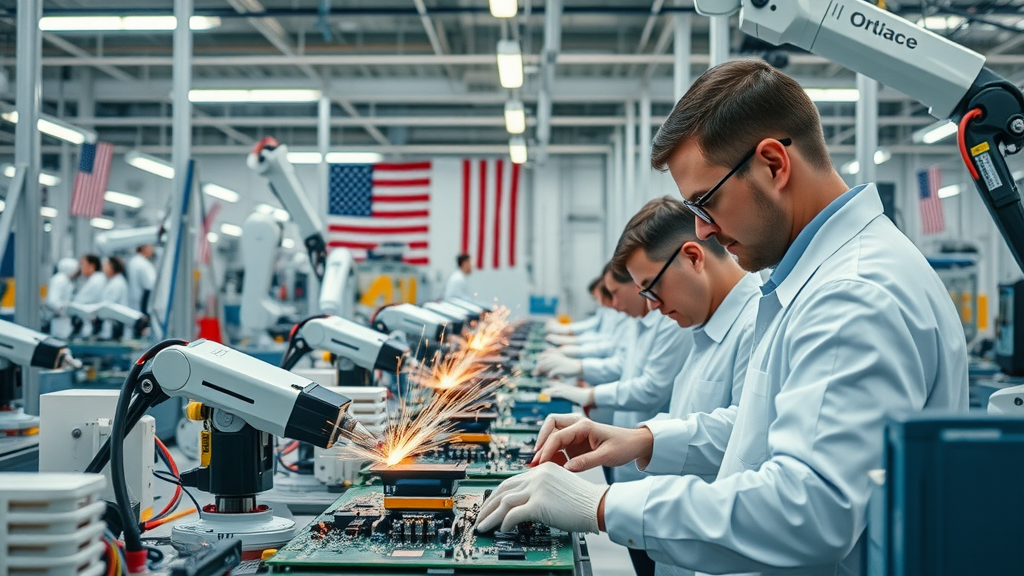

By prioritizing reshoring initiatives, electronics manufacturers gain greater control over quality control, dramatically reduce lead times, and boost supply chain resilience. These practices ensure that production disruptors—natural disasters, pandemics, and changing trade policies—have less opportunity to grind production to a halt. Electronics supply chain reshoring not only strengthens domestic manufacturing jobs, but enhances oversight and fosters innovation by bringing R&D and manufacturing back home.

Why Electronics Manufacturing is Moving Back: Supply Chains and Labor Costs

Global shifts in labor costs have closed the gap in production costs between overseas and domestic operations.

Tariffs, trade tensions, and unpredictable trade policies add hidden costs and risk, making reshoring more attractive for electronics manufacturing.

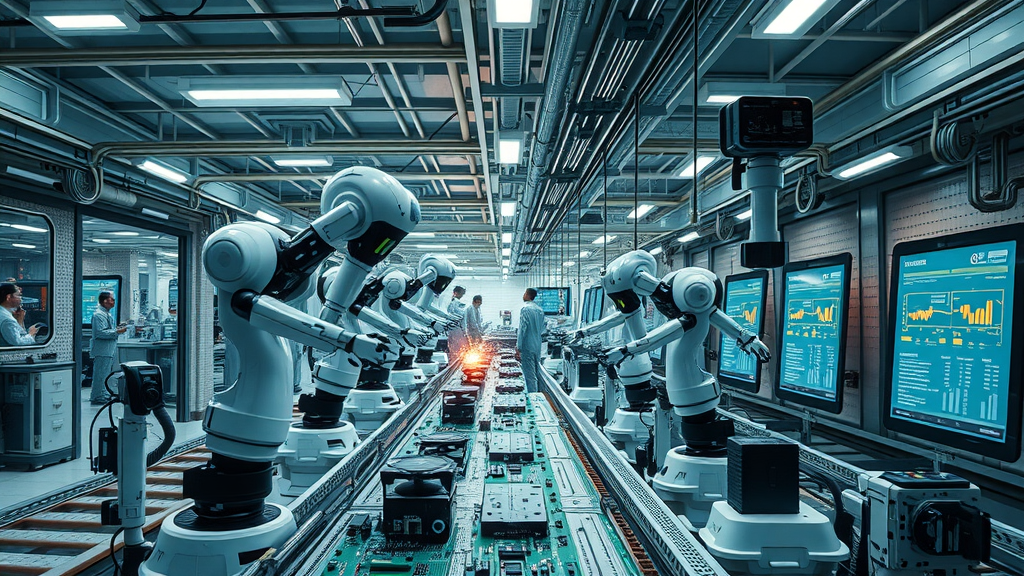

Advanced manufacturing technologies—such as robotics and AI-powered digital supply chains—enable competitive domestic production and offset rising labor costs.

The rising labor costs in key offshoring regions, when combined with the risks of global supply chain disruptions, have persuaded many companies in electronics manufacturing to reevaluate previous offshoring arrangements. Turning to reshoring brings not only potential cost savings by leveraging smart automation and reducing transportation expenses, but also supports domestic production growth, revitalizes manufacturing jobs, and streamlines supplier management.

The Reshoring Initiative: Driving Change in the Electronics Industry

"The reshoring initiative is not just a trend—it's an industry-wide recalibration driven by risk, innovation, and quality improvement." - Industry Analyst

The reshoring initiative in electronics manufacturing is catalyzing a new era of global competition. Industry leaders are investing in North American facilities, forming collaborative alliances, and targeting government incentives to encourage investment in domestic supply chains. As technology evolves and policy environments shift, electronics companies focused on supply chain resilience and robust quality control will be best prepared for future disruptions.

Major electronics manufacturers now realize that managing risk and ensuring consistent product quality are business-critical. Reshoring makes these goals achievable by allowing direct oversight of production processes, supply chain transparency, and streamlined logistics—while supporting the development of advanced domestic manufacturing ecosystems.

People Also Ask About Electronics Supply Chain Reshoring

What is reshoring in supply chain?

Reshoring refers to moving electronics manufacturing and assembly processes back to a manufacturer's home country after having previously offshored them to lower-cost regions.

Unlike offshoring (outsourcing overseas) or nearshoring (moving production to nearby countries), electronics supply chain reshoring emphasizes local control, enhanced quality, and supply chain resilience.

Reshoring enables electronics manufacturers to regain direct oversight, enhance quality control, and respond more quickly to market shifts. In contrast, offshoring often extends lead times and increases risk with complex, spread-out supply chains. Nearshoring provides some of the benefits of proximity, but only reshoring brings manufacturing entirely back home for optimal control and minimum disruption.

Is reshoring happening in the US?

Recent years have seen a marked increase in electronics manufacturing returning to US soil, as companies seek to counteract global supply chain disruptions and gain a competitive edge.

Case studies from leading US electronics manufacturers—such as expansions of semiconductor fabrication plants in Arizona and Texas—demonstrate successful shifts to domestic production and manufacturing back home.

The US is at the forefront of the reshoring initiative in electronics. Companies large and small have announced major investments in domestic facilities, citing the need for short lead times and decreased reliance on foreign-sourced electronic components. As more electronics manufacturing shifts back home, North America is poised to lead innovation and create higher-value manufacturing jobs.

What is supply chain restructuring?

Supply chain restructuring involves making changes to a company's end-to-end sourcing, logistics, and production processes for greater efficiency and risk management.

Unlike complete reshoring, supply chain restructuring may combine onshoring, nearshoring, and offshoring, while addressing critical vulnerabilities exposed by recent disruptions in electronics manufacturing.

For electronics manufacturers, supply chain restructuring can mean supplementing overseas operations with domestic assembly, creating redundancies in critical component sourcing, and digitizing supply network management to proactively manage risk. Modern supply chain resilience goes beyond cost savings—it’s about flexibility, speed, and preparedness for any disruption.

What are some of the difficulties that the electronics industry is facing?

Global supply chain constraints: From natural disasters to geo-political turmoil, electronics manufacturers have experienced a perfect storm of disruptions affecting vital raw materials and components.

Scarcity of semiconductor components: The electronics industry remains especially vulnerable to chip shortages, driving up lead times and slowing production across scores of products.

Rising logistics costs and labor shortages: Transportation crises and fierce competition for skilled workers increase overall supply chain costs while adding complexity to every link in the electronics supply chain.

These difficulties have forced companies to rethink their reliance on global supply chains, search for new suppliers, diversify sourcing strategies, and invest heavily in digital transformation to ensure better visibility at every step of the process.

Key Drivers of Electronics Supply Chain Reshoring

Mitigating Risks: Supply Chains, Resilience, and Quality Control

Supply chain resilience is essential as electronics manufacturers face increasing volatility in both demand and logistics.

Reshoring enables enhanced quality control by allowing direct oversight, resulting in fewer product defects and speedier corrective actions.

Shortened lead times and improved supply chain agility are additional benefits, ensuring customer demands can be met even in crisis events.

Building resilient electronics supply chains through reshoring means manufacturers can respond rapidly to evolving threats, whether they are global pandemics or trade disruptions. By returning production back home, companies better control quality assurance, reduce corrective delays, and benefit from locally-sourced materials. This flexibility is particularly vital for high-margin or mission-critical electronic components where performance and reliability cannot be compromised.

Additionally, domestic manufacturing facilitates seamless integration between product designers, engineers, and factory teams—further driving innovation and greater accountability throughout supply chain operations.

Cost Savings and the Challenge of Labor Costs

Comparison of Labor, Transportation, and Total Cost Savings: Offshore vs. Reshored Electronics Manufacturing |

||

Factor |

Offshore Manufacturing |

Reshored Manufacturing |

|---|---|---|

Labor Costs |

Low (but rising) |

Higher, offset by automation |

Transportation Costs |

High (long shipping routes, port fees) |

Low (domestic logistics, faster delivery) |

Total Cost |

Often lower, but more volatile (hidden costs from disruptions) |

Increasingly competitive (stable, fewer delays) |

Lead Times |

Weeks to months |

Days to weeks |

Quality Control |

Difficult oversight, higher risk of defects |

Strong oversight, enhanced quality |

Rising labor costs abroad, coupled with mounting expenses in global transportation and compliance, tip the cost equation further in favor of reshoring. Electronics manufacturers that successfully leverage automation, robotics, and digital supply chains can close the labor cost differential, while saving millions in logistics and avoiding the hidden price of disruptions.

While up-front investments may be higher domestically, the long-term cost savings from decreased lead times, more reliable logistics, and better quality control contribute directly to sustained competitive advantage. The key is balancing the initial outlay for advanced technologies against the value of stability and risk reduction.

Tariffs, Trade Tensions, and the Global Electronics Supply Chain

New and shifting global trade policies have increased the cost of importing electronic components while encouraging local investments through incentives or tariffs.

Electronics manufacturers are reevaluating their sourcing and production models to account for long-term supply chain resilience, safety, and cost transparency.

Tariffs not only drive up direct costs, but also add risk by making it harder to forecast future pricing and profit margins. In response, companies are focusing on building domestic supplier networks, obtaining government support, and adopting a more agile approach to supply chain management to sidestep international unpredictability.

Trade tensions are expected to remain high, making electronics supply chain reshoring a crucial hedge against volatility, sudden regulation changes, or future trade barriers. Being closer to end customers can also result in improved customer service, higher reliability, and greater growth potential.

Step-by-Step Guide: Mastering Electronics Supply Chain Reshoring

Assessing Supply Chain Vulnerabilities and Mapping Your Reshoring Initiative

Begin by mapping every supplier and process in your current electronics supply chain, ranking them by risk, location, and criticality. Assess vulnerabilities—from sole-sourced electronic components to suppliers in high-risk regions—and run scenario planning for disaster events or major delays. This evaluation is the cornerstone of a successful reshoring initiative.

After identifying at-risk nodes, companies develop phased plans for shifting critical processes and high-value production back home. This often starts with the most vulnerable supply chains or products with the highest margins, then expands to supporting suppliers and secondary assemblies. Digital supply chain mapping tools make this process more transparent, helping visualize alternative networks and cost impacts.

Strategic Supplier Selection and Building Domestic Value Chains

Choosing the right domestic suppliers involves more than just cost comparisons. Prioritize suppliers with proven reliability, commitment to innovation, and robust quality control practices. Building strong partnerships with local sources not only reduces logistics risk but ensures quicker response times, which are vital for electronics manufacturers working with complex, rapidly evolving product lines.

Engage in collaborative planning with your chosen suppliers, co-develop digital integration strategies, and align quality benchmarks. By investing in domestic value chains, companies create a resilient, well-connected ecosystem less likely to be disrupted by global shocks. Every step taken toward local sourcing should fit into your broader supply chain resilience strategy, ensuring flexibility and competitiveness.

Implementing Quality Control for Electronics Manufacturing Back Home

Deploy next-gen inspection technologies—such as AI-driven vision systems and big data analytics—to catch defects early and continuously monitor process efficiency.

Invest in regular training for your workforce to ensure supply chain resilience and up-to-date skills in electronics production and quality standards.

Directly managing quality control is easier and more effective when electronics manufacturing is back home. With robust in-factory testing and instant feedback loops, manufacturers can quickly adjust production settings and eliminate defects. This results in faster lead times, lower warranty costs, and higher customer satisfaction.

Continuous improvement processes and worker training keep domestic operations agile and informed about the latest quality standards, helping companies adapt rapidly to supply chain changes without sacrificing product reliability. This focus on local accountability is central to building and maintaining world-class electronics manufacturing operations.

Leveraging Technology: Digital Supply Chains & Automation

Adopt smart manufacturing: Integrate data analytics and cloud-based platforms to monitor supply chain health, demand spikes, and production bottlenecks in real time.

Use robotics and automation to standardize processes, manage labor costs, and maintain high production quality—even as demand shifts quickly.

A digital-first approach to electronics supply chain reshoring relies on full supply network visibility, consistent predictive analytics, and automated production lines. Smart sensors and IoT devices generate early alerts for supply chain risks, while robotics in assembly plants deliver consistent quality at reduced labor costs. Digital twin technology further models supply chain scenarios, helping manufacturers fine-tune production optimization strategies while mastering risk management.

Modernizing your electronics manufacturing back home with these technologies secures long-term cost savings, sharper competitiveness, and the ability to adapt instantly during times of crisis or surges in demand.

Case Studies: Reshoring Electronics Manufacturing

Industry leaders such as major contract electronics manufacturers and semiconductor giants have successfully brought production home, reporting improved cost savings and fewer supply chain disruptions.

Valuable lessons include strategic use of government incentives, relentless focus on quality control, and ensuring domestic talent pipelines for sustained growth.

One leading electronics manufacturer reduced transportation delays by 70% and minimized costly defects by centralizing sensitive production processes in the US. Another firm shifted manufacturing operations to North America, achieving greater flexibility and the ability to bring innovations to market faster—even in times of global trade instability.

These real-world examples demonstrate that the move toward electronics supply chain reshoring yields more than headlines—it brings quantifiable financial and operational benefits, from workforce expansion to competitive differentiation.

Challenges and Pitfalls in Electronics Supply Chain Reshoring

Addressing Labor Cost and Talent Shortages

While labor costs can be offset by automation, the electronics industry faces talent shortages in high-demand roles—including automation specialists, engineers, and skilled line workers. Building strong training programs and partnering with educational institutions helps develop the workforce necessary for sustainable reshoring.

Companies that overlook talent development may find domestic production bottlenecked by capacity or quality issues, negating potential cost savings and complicating supply chain resilience efforts.

Infrastructure and Regulatory Barriers for Electronics Manufacturing

Reshoring initiatives often confront gaps in physical infrastructure—such as outdated facilities or lack of advanced logistics networks. Navigating diverse regulatory requirements for safety, environmental compliance, and labor practices also requires careful planning and ongoing investment.

Overcoming these obstacles demands coordinated public-private partnerships and a willingness to adapt manufacturing operations for both compliance and efficiency, while leveraging government incentives when available.

Managing Complex Global Supply Chains During Reshoring

Balancing cost savings with secure, high-quality production remains an ongoing challenge, especially when transitioning legacy supply chains to mixed or fully domestic models.

Maintaining supply chain resilience requires strong backup plans and diversified sources, even after reshoring, to ensure continuous operations in the face of new disruptions.

"While supply chain reshoring offers competitive advantages, companies must weigh talent shortages and logistical challenges carefully." - Supply Chain Director

A practical approach involves incremental reshoring—focusing on the most vulnerable segments of the electronics supply chain, building confidence with each success, and remaining adaptable as both market conditions and regulatory frameworks evolve.

Electronics Supply Chain Reshoring: Pros, Cons, and Recommendations

Reshoring vs. Offshoring: Key Factors for Electronics Manufacturing |

||

Factor |

Reshoring |

Offshoring |

|---|---|---|

Cost |

Potentially higher up-front, but stable and with fewer disruptions |

Lower, but hidden and rising costs due to global risks |

Quality Control |

Direct oversight, high consistency |

Challenging to manage, higher risk of defects |

Risk |

Lower (greater resilience to disruptions) |

Higher (exposed to global volatility) |

Flexibility |

High (rapid response to change) |

Low (longer lead times, rigid structure) |

-

Best Practices:

Thoroughly evaluate current vulnerabilities and map out supply chains.

Invest in digital and automation solutions to offset labor and production costs.

Build and nurture trusted supplier relationships domestically.

Focus relentlessly on quality control and workforce training.

Leverage government incentives and partnerships for infrastructure upgrades.

"Effective quality control and robust supplier partnerships are the cornerstones of successful electronics supply chain reshoring." - Industry Consultant

Watch an in-depth expert commentary and infographic breakdown on evolving global electronics supply chains, future trends in reshoring, and how advanced technologies are shifting competitive dynamics.

FAQs: Electronics Supply Chain Reshoring

How does electronics supply chain reshoring improve quality control?

Reshoring electronics manufacturing empowers companies with direct oversight over production processes. This proximity allows real-time audits, immediate feedback loops, and standardized protocols, leading to fewer defects and higher reliability. As a result, manufacturers can meet stricter quality demands while building stronger relationships with domestic suppliers.

What investments are needed for successful electronics supply chain reshoring?

Successful reshoring typically requires capital in facility upgrades, workforce training, advanced automation, and robust digital supply chain platforms. These investments may seem significant initially, but they translate into long-term cost savings, improved quality, and lower risk of future disruptions in the electronics industry.

Is electronics supply chain reshoring suitable for every manufacturer?

Not every electronics manufacturer may benefit equally from reshoring. The decision depends on supply chain complexity, product type, and cost structures. Companies handling sensitive, high-margin products or requiring fast turnaround are prime candidates; others may opt for hybrid models combining global sourcing with targeted reshoring for the most critical components.

Key Takeaways: Mastering Electronics Supply Chain Reshoring

Assess vulnerabilities and map your electronics supply chain—from raw materials through delivery.

Embrace digital technology and automation to offset labor costs and enhance supply chain resilience.

Prioritize domestic supplier relationships and continuous quality control improvements.

Balance initial investments with the long-term benefits of stability, agility, and competitive differentiation.

Stay informed on policy changes and act swiftly to maintain your advantage as the global landscape evolves.

Conclusion: Take Control of Your Electronics Supply Chain Reshoring Journey

Electronics supply chain reshoring offers greater stability, improved quality, and risk reduction. For manufacturing leaders, acting promptly ensures competitiveness and protects against global shocks.

Stay Ahead: Subscribe for Essential Global Trade & Electronics Supply Chain Reshoring Updates

Manufacturer, don't miss out! Stay informed on global trade shifts—tariffs, reshoring, and supply chain updates could reshape your strategy. Subscribe to Global Trade News for the latest updates. Call 203-271-7991 today.

Add Row

Add Row  Add

Add

Write A Comment